Hardened matt hot-molten composite film and preparation method thereof

A composite film and matte technology, applied in the direction of chemical instruments and methods, flat products, other household appliances, etc., can solve problems such as damage, insufficient coating firmness, etc., and achieve the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

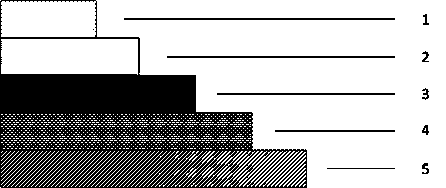

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] The invention provides a hardened matte hot-melt composite film, the structure of which is figure 1 As shown, the composite film has a five-layer structure, which is a hardened matte UV coating 1, a substrate layer 2, an adhesion-promoting layer 3, an adhesion-promoting layer 4, and a hot-melt resin layer 5 from top to bottom. The base layer 2 is composed of hot melt resin particles through melt extrusion and the base layer composite hot melt resin layer 5, the base layer 2 is coated with a hardened matte UV coating 1, between the base layer 2 and the base layer An adhesion-promoting layer 3 and an adhesion-promoting layer 4 are added between the hot-melt resin layers 5 .

[0024] The base material layer is made of one of polyethylene terephthalate, polypropylene, polyvinyl chloride and polycarbonate film, with a thickness of 10-200um.

[0025] The hot-melt resin i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com