Automatic winding device of PVB film production line

A technology of winding device and production line, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., which can solve the problems of inconvenient cutting and lower production efficiency, and achieve the goal of improving winding efficiency and saving manpower for loading materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

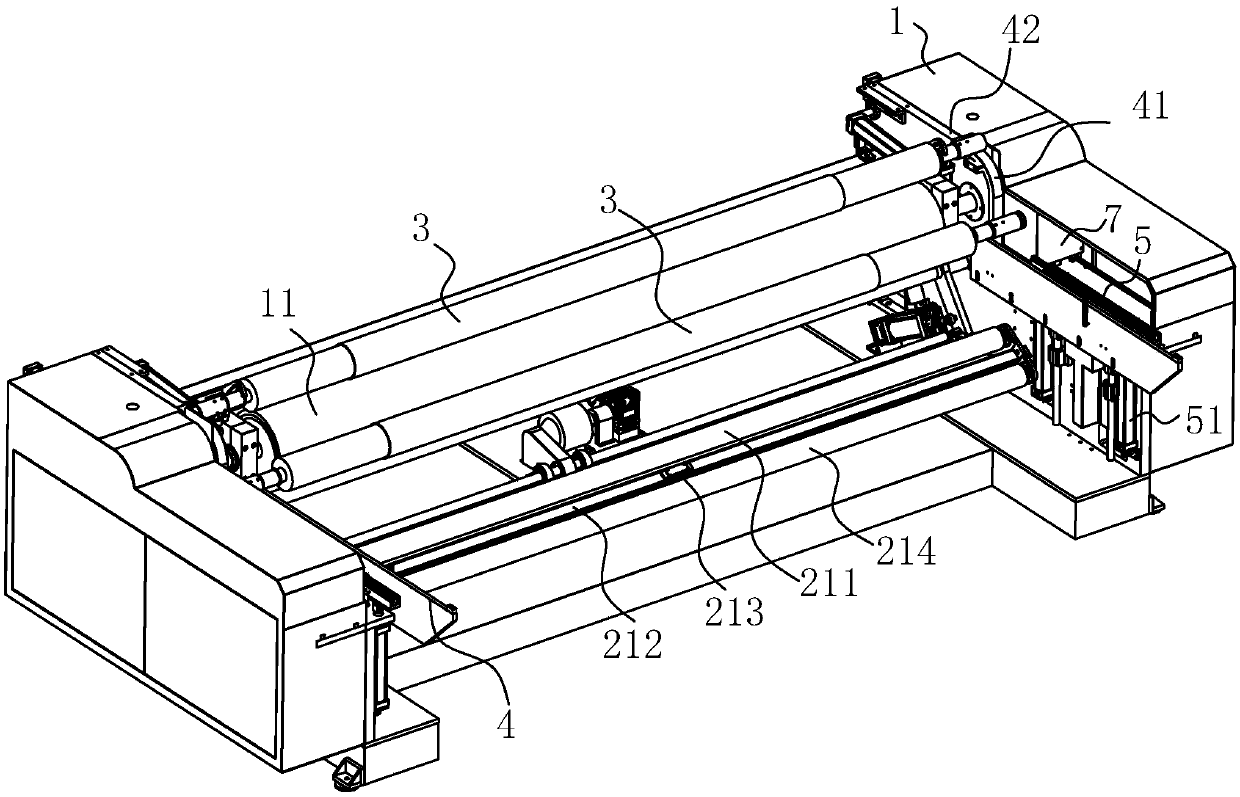

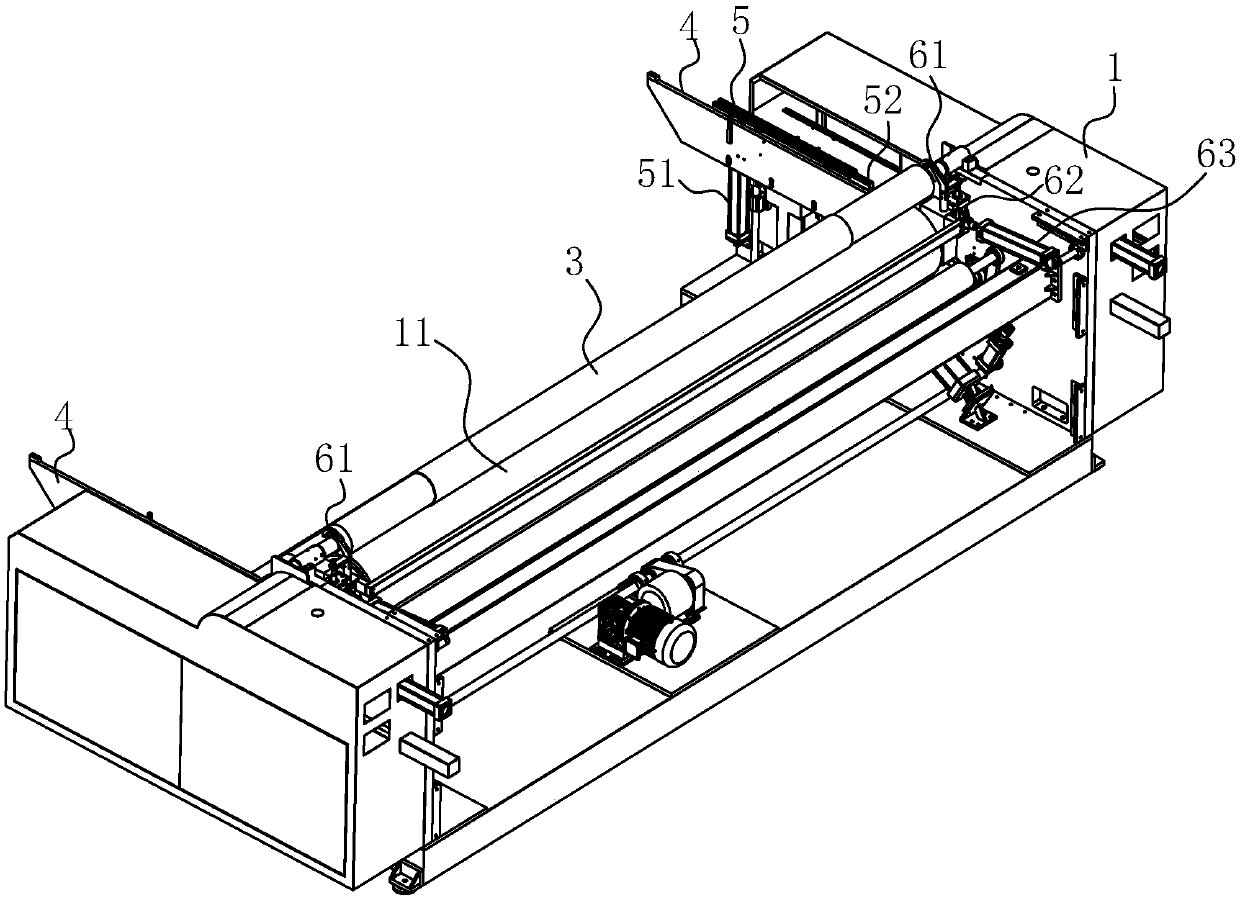

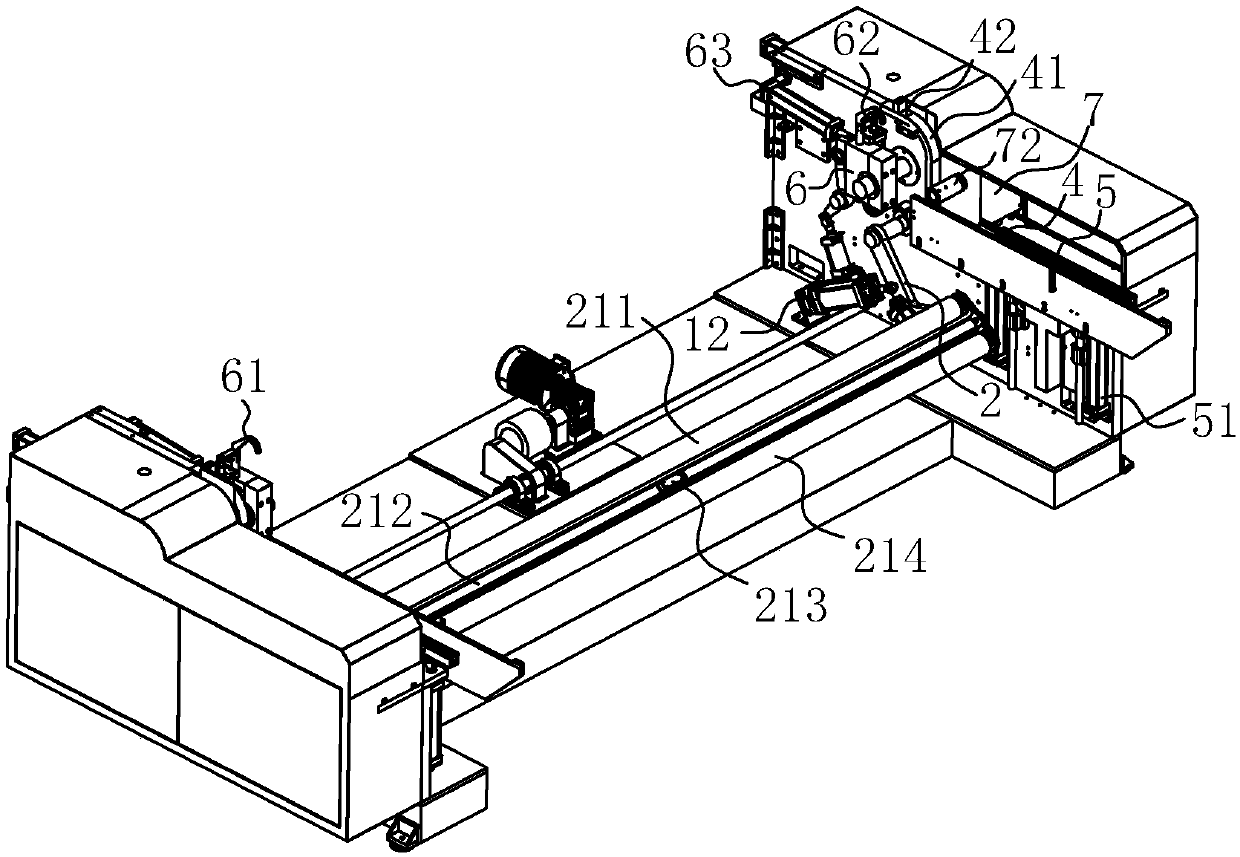

[0035] refer to figure 1 as well as figure 2 , is the automatic rewinding device of a kind of PVB film production line disclosed by the present invention, comprises frame 1, is connected with the support roll 11 that PVB film is rotatably supported on frame 1, and support roll 11 is arranged along the width direction of PVB film, During conveying, the PVB film bypasses from the top of the support roller 11, and the support roller 11 supports the PVB film, and a take-up roller 3 is also provided on the frame 1 parallel to the support roller 11, and the take-up roller 3 rotates and is arranged on the frame 1, the PVB film passes through the gap between the winding roller 3 and the supporting roller 11 after bypassing the support roller 11, and is fixed on the surface of the winding roller 3, and the winding roller 3 is rotated to wind the PVB film to On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com