Post-treatment method of tert butyl alcohol containing tert-butyl hydroperoxide

A technology of tert-butyl hydroperoxide and tert-butanol, which is applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of high energy consumption, achieve low energy consumption, mild reaction conditions, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

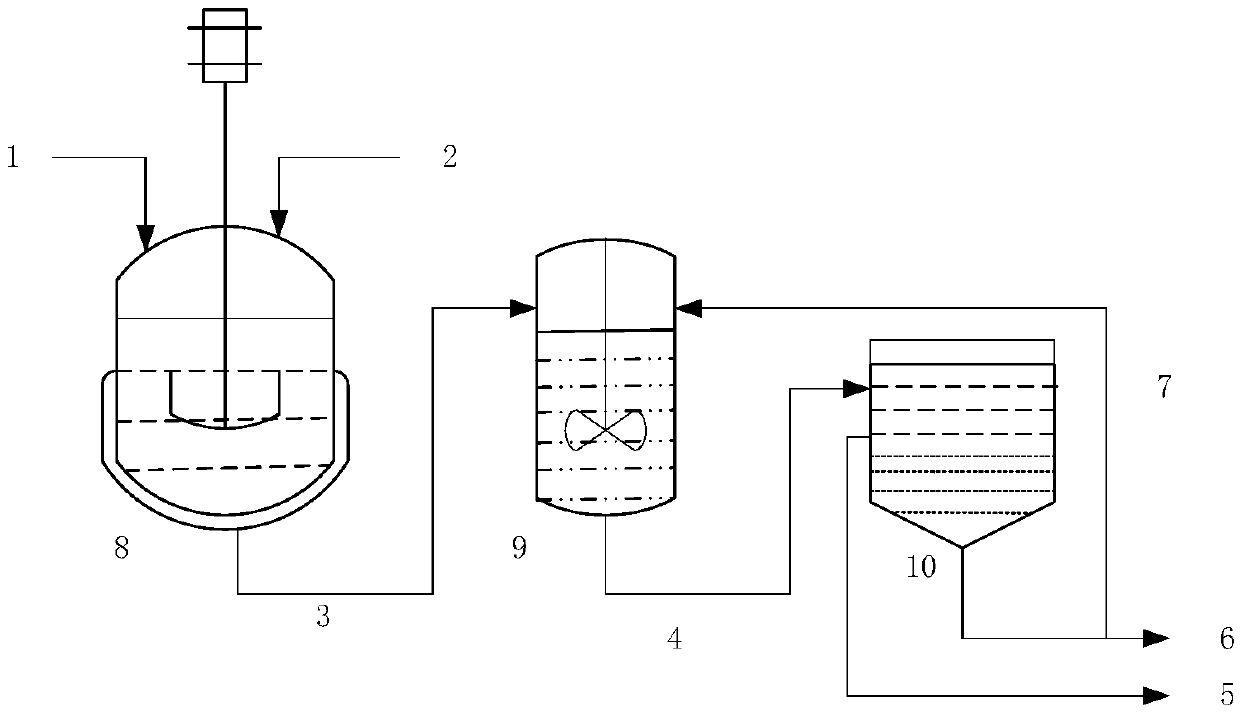

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0033] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0035] In the four-neck flask (water bath temperature control) that is equipped with thermometer, constant pressure dropping funnel and condensing tube 1000ml, add 190g concentration and be the sodium sulfite aqueous solution of 18.7%, stir, add TBA-TBHP solution 39.5g in dropping funnel ( TBHP content 61.8wt%), slowly add dropwise to the sodium sulfite aqueous solution, control the temperature at 50° C., and continue stirring for 10 minutes after the dropwise addition is completed in 30 minutes. The temperature was lowered to 30° C., and the layers were left to stand. After separation, 32 g of tert-butanol was obtained. Gas chromatographic detection showed that TBA and the water phase did not contain TBHP, and TBA contained 32% water, and did not contain sodium sulfate and sodium sulfite.

Embodiment 2

[0037] In the four-neck flask (water bath temperature control) that is equipped with thermometer, constant pressure dropping funnel and condenser tube 1000ml, add 190g concentration and be the sodium sulfite aqueous solution of 18.7%, stir, add TBA-TBHP solution 40g (TBHP in dropping funnel) Content 50wt%), slowly added dropwise to the sodium sulfite aqueous solution, the temperature was controlled at 50° C., and after 30 minutes the dropwise addition was completed, the stirring was continued for 10 minutes. The temperature was lowered to 30° C., and the layers were left to stand. After separation, 33.5 g of tert-butanol was obtained. Gas chromatographic detection showed that TBA and the water phase did not contain TBHP, and TBA contained 31.5% water, and did not contain sodium sulfate and sodium sulfite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com