Modified multi-block allyl amine demulsifier and preparation method thereof

An allyl amine demulsifier and multi-block technology, which is applied in the field of modified multi-block allyl amine demulsifier and its preparation, can solve the problem of unsatisfactory demulsification effect and poor wide-spectrum adaptability of different crude oil products, etc. problem, to achieve good universality and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

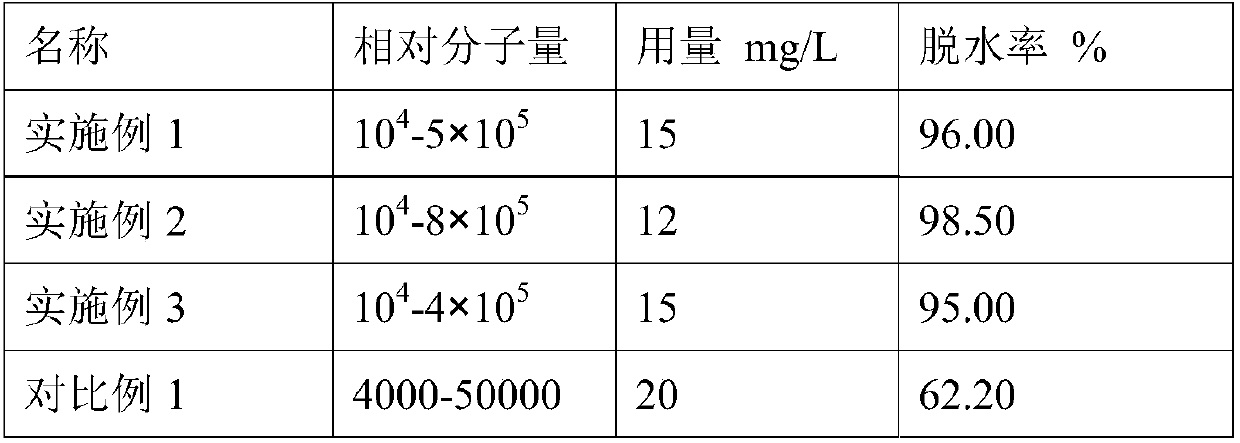

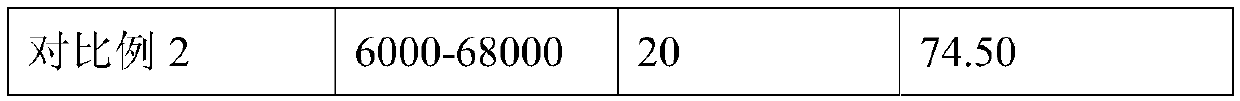

Examples

Embodiment 1

[0026] 1) 40 grams of starter allylamine and 4 grams of AlCl 3 Put it into a reactor equipped with a stirring and condensing device, heat up to 115-145°C, control the pressure in the reaction vessel below 0.4MPa, feed 600 grams of ethylene oxide to fully react, and then vacuumize to remove unreacted epoxy Ethane and small molecule by-product; Pass into 600 gram propylene oxide and 400 gram butylene oxide then under the same condition, after fully reacting, vacuumize and remove unreacted propylene oxide and butylene oxide, obtain initial product;

[0027] 2) Dissolve 400 grams of the initial product obtained in step 1) in 350 grams of ethanol, and then add 6 grams of azobisisobutyronitrile and 2 grams of OP-10 into a reactor with stirring, condensation, and dropping devices , start the stirrer, heat up to 65°C, slowly add 200 g of α-methyltriethoxysilane dropwise under stirring, control the dropwise addition for 1.5 hours, continue the reaction for 2 hours, and distill off the ...

Embodiment 2

[0029] 1) 16 grams of starter allylamine and 10 grams of AlCl 3 Put it into a reactor with a stirring and condensing device, heat up to 115-145°C, control the pressure in the reaction vessel below 0.4MPa, feed 320 grams of ethylene oxide to fully react, and then vacuumize to remove unreacted epoxy Ethane; Then pass into 660 gram propylene oxide and 320 gram butylene oxide under the same condition, after fully reacting, vacuumize and remove unreacted propylene oxide and butylene oxide, obtain initial product;

[0030] 2) Dissolve 600 grams of the initial product obtained in step 1) in 300 grams of ethanol, and then add 10 grams of azobisisobutyronitrile and 6 grams of OP-10 into a reactor with a stirring, condensation, and dropping device , start the agitator, heat up to 50°C, slowly add 160 g of α-methyltriethoxysilane dropwise under stirring, control the dropwise addition for 0.5 hours, continue the reaction for 0.5 hours, and distill off the solvent under reduced pressure to...

Embodiment 3

[0032] 1) 160 grams of starter allylamine and 20 grams of AlCl 3 Put it into a reactor equipped with a stirring and condensing device, heat up to 115-145°C, control the pressure in the reaction vessel below 0.4MPa, feed 660 grams of ethylene oxide to fully react, and then vacuumize to remove unreacted ethylene oxide Alkane; Pass into 520 gram propylene oxide and 350 gram butylene oxides under the same condition then, vacuumize after fully reacting and remove unreacted propylene oxide and butylene oxide, obtain initial product;

[0033] 2) Dissolve 100 grams of the initial product obtained in step 1) in 450 grams of ethanol, and then add 1.5 grams of azobisisobutyronitrile and 3 grams of OP-10 into a reactor with a stirring, condensation, and dropping device , start the agitator, heat up to 80°C, slowly add 450 g of α-methyltriethoxysilane dropwise under stirring, control the dropwise addition for 1.5 hours, continue the reaction for 2 hours, and distill off the solvent under r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com