Gear oil for assembly of new energy automobiles

A new energy vehicle and gear oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of easy corrosion of gear oil and difficulty in regeneration treatment, and achieve good low-temperature flow, good high-temperature oxidation stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This implementation provides that the present invention provides a new energy automobile assembly gear oil, which is composed of the following components in terms of mass percentage: 92% di-octyl sebacate (castor oil derivative), 2,6 di-tert-butyl Hydroquinone 2.0%, sodium petroleum sulfonate 1.0%, tricresyl phosphate 3.0%, polyacrylate 0.004%, polymethacrylate 0.416%, palmitic acid 0.08%, polymethacrylate 1.5%.

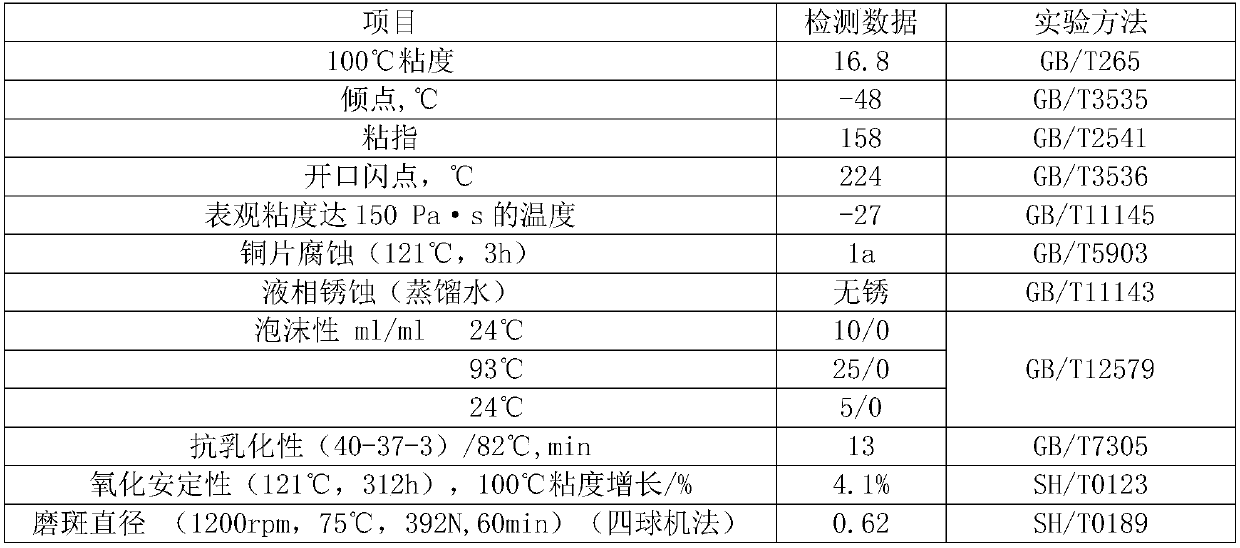

[0028] The performance of the new energy vehicle assembly gear oil in this implementation was tested, and the results are as follows:

[0029]

[0030] From the above experimental data, it can be seen that this new gear oil not only has good high temperature oxidation stability but also has excellent low temperature fluidity, and is suitable for the climate in most regions of China.

Embodiment 2

[0032] This implementation provides that the present invention provides a new energy automobile assembly gear oil, which is composed of the following components in terms of mass percentage: 88.669% of sucrose polyester, 3.0% of nonyl diphenylamine, 0.4% of calcium petroleum sulfonate, phosphoric acid Tricresyl is 4.2%, polyacrylate is 0.001%, polymethacrylate is 1.5%, palmitic acid is 0.03%, and polyisobutylene is 2.2%.

[0033] Among them, the degree of esterification of sucrose polyester is 7.

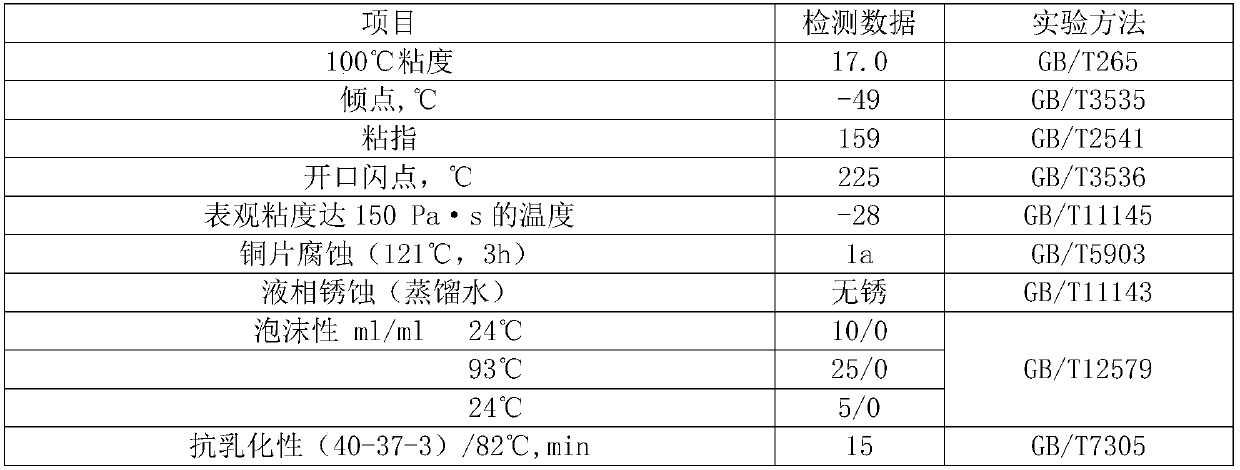

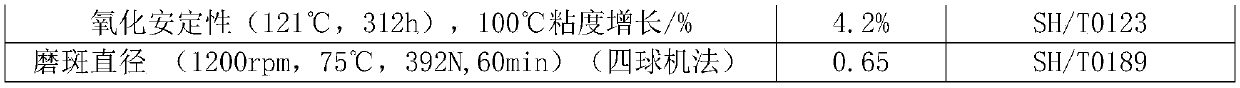

[0034] The performance of the new energy vehicle assembly gear oil in this implementation was tested, and the results are as follows:

[0035]

[0036]

[0037] From the above experimental data, it can be seen that this new gear oil not only has good high temperature oxidation stability but also has excellent low temperature fluidity, and is suitable for the climate in most regions of China.

Embodiment 3

[0039] This implementation provides that the present invention provides a new energy vehicle assembly gear oil, which is composed of the following components in terms of mass percentage: hydrogenated rapeseed oil is 92.065%, nonyl diphenylamine is 0.4%, petroleum calcium sulfonate is 1.8%, Chlorinated paraffin was 2%, polyacrylate was 0.05%, poly-alpha olefin was 1.5%, sulfurized whale oil was 0.03%, and hydroxymethylcellulose was 2.2%.

[0040] The performance of the new energy vehicle assembly gear oil in this implementation was tested, and the results are as follows:

[0041]

[0042] From the above experimental data, it can be seen that this new gear oil not only has good high temperature oxidation stability but also has excellent low temperature fluidity, and is suitable for the climate in most regions of China.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com