New material with high magnetic-conductivity property and manufacturing method

A production method and high magnetic permeability technology, which are applied in the fields of instruments, electrical digital data processing, transportation and packaging, etc., can solve the strict requirements of the magnetic permeability of sensing series products, reduce the economic value and benefit of magnetic conductive materials, The problems of poor magnetic permeability of magnetic conductive materials, etc., can achieve the goal of magnetic permeability, increase economic value and benefits, and have rich ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

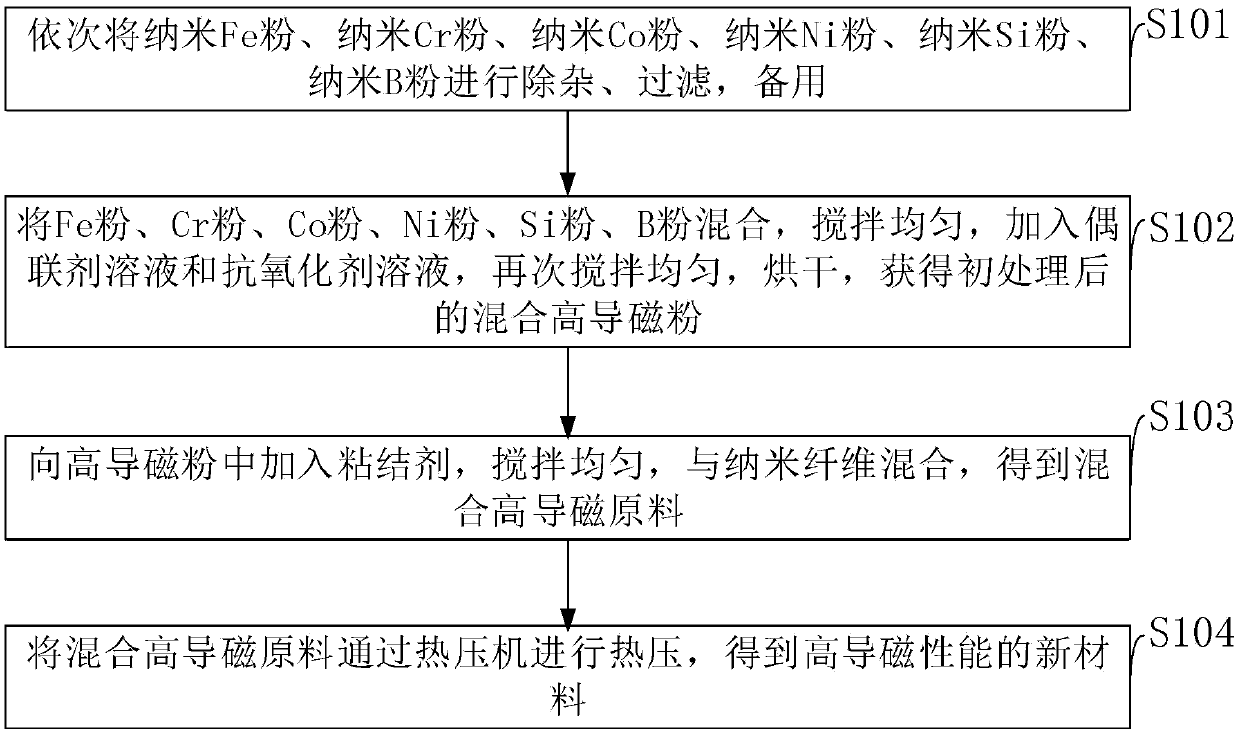

Method used

Image

Examples

Embodiment 1

[0103] The new material with high magnetic permeability provided by the embodiments of the present invention consists of 70 parts of nano-Fe powder, 20 parts of nano-Cr powder, 15 parts of nano-Co powder, 20 parts of nano-Ni powder, 10 parts of nano-Si powder, and 10 parts of nano-Si powder according to the mass parts. 15 parts of powder, 10 parts of nanofiber, 2 parts of binder, 2 parts of coupling agent, 5 parts of heat stabilizer, and 3 parts of antioxidant.

Embodiment 2

[0105] The new material with high magnetic permeability provided by the embodiments of the present invention consists of 80 parts of nano-Fe powder, 30 parts of nano-Cr powder, 25 parts of nano-Co powder, 30 parts of nano-Ni powder, 30 parts of nano-Si powder, and 30 parts of nano-Si powder according to the mass parts. 20 parts of powder, 14 parts of nanofiber, 6 parts of binder, 6 parts of coupling agent, 9 parts of heat stabilizer, and 5 parts of antioxidant.

Embodiment 3

[0107] The new material with high magnetic permeability provided by the embodiments of the present invention consists of 75 parts of nano-Fe powder, 25 parts of nano-Cr powder, 20 parts of nano-Co powder, 25 parts of nano-Ni powder, 20 parts of nano-Si powder, and 20 parts of nano-Si powder according to the mass parts. 17.5 parts of powder, 12 parts of nanofiber, 4 parts of binder, 4 parts of coupling agent, 7 parts of heat stabilizer, and 4 parts of antioxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com