A kind of solid antibacterial lubricating film layer with high binding force of space mechanism and preparation method thereof

A bonding force and lubricating film technology, applied in coating, vacuum evaporation coating, metal material coating process, etc., can solve the problems of accelerating the release of harmful gases from materials, endangering the life safety of astronauts, accelerating material aging, etc. The binding force, the antibacterial effect is lasting, the binding force improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

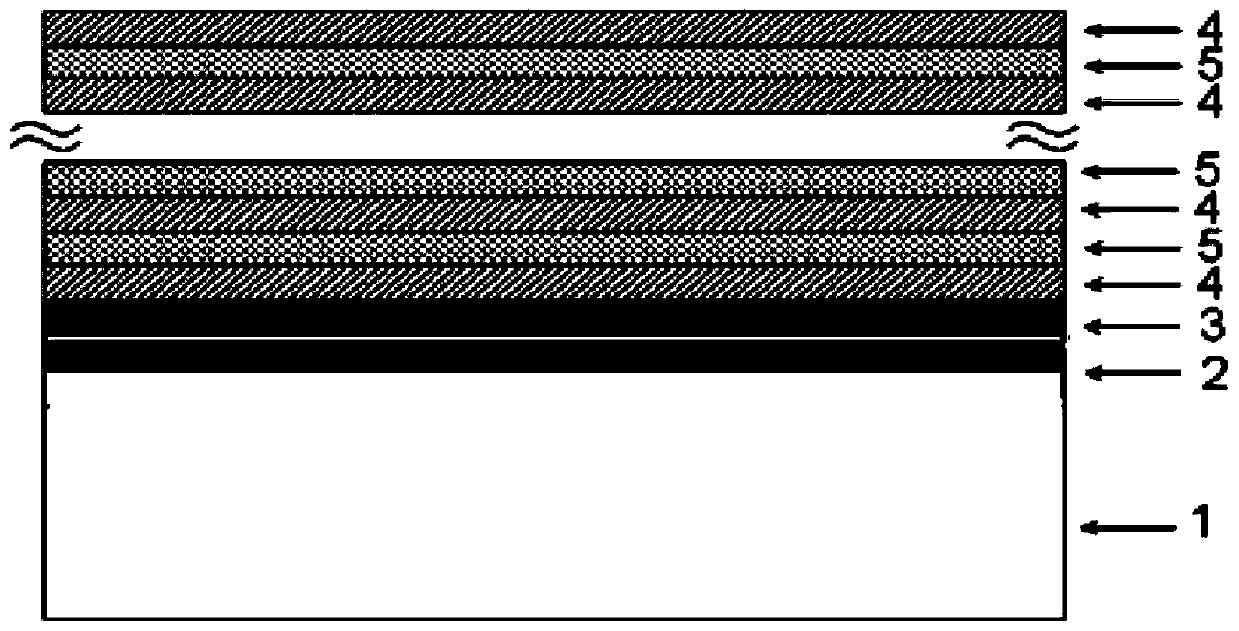

[0027] The structural representation of the solid antibacterial lubricating film layer product of the space mechanism high binding force of the present invention, see figure 1 , where 1-substrate, 2-binding layer (Ti), 3-transition layer (TiN), 4-functional layer (MoS 2 -Cu-Ag), 5-functional layer (TiN).

[0028] The high-binding force solid antibacterial lubricating film layer product of the space mechanism includes: Ti / TiN / (TiN / MoS with a substrate of TC4 titanium alloy and a thickness of 2 μm 2 -Cu-Ag) nanocomposite multilayer film;

[0029] The specific preparation process is carried out in the following steps.

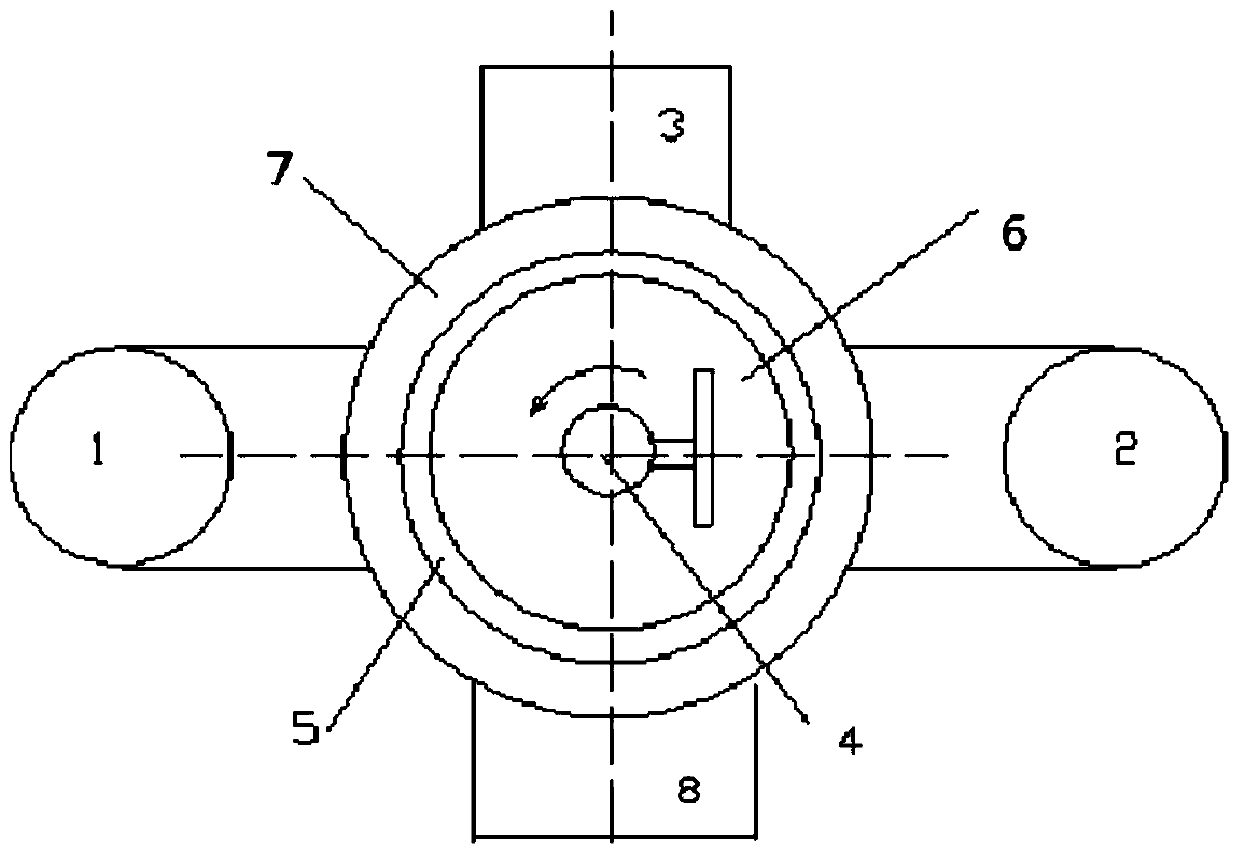

[0030] 1) Sputtering cleaning: the plated sample TC4 titanium alloy 6 is surface polished, ultrasonically cleaned with acetone, ultrasonically cleaned with ethanol and dried, then placed in figure 2 On the rotatable target platform 4 in the shown coating equipment, the vacuum chamber 7 is evacuated to 5.0×10 -3 Pa, through Ar, the control air pressure is 3.0×...

Embodiment 2

[0037] Under high load conditions, in order to improve the toughness of the coating and prevent the coating from peeling off due to brittle fracture, the preparation time of the TiN film layer in step 4 in Example 1 was shortened from 30min to 10min, and MoS 2 -The preparation time of Cu-Ag film layer is shortened from 30min to 10min, and the number of corresponding multilayer layers is increased from 12 to 36, and the outermost layer is MoS 2 -Cu-Ag film layer and keep the total thickness of film layer consistent, other steps are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com