Preparation method of high-strength high-toughness zirconia nano-fiber

A nanofiber, tough zirconia technology, applied in the direction of inorganic raw material rayon, can solve the problems of limited application and low tensile strength, and achieve the effects of simple operation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

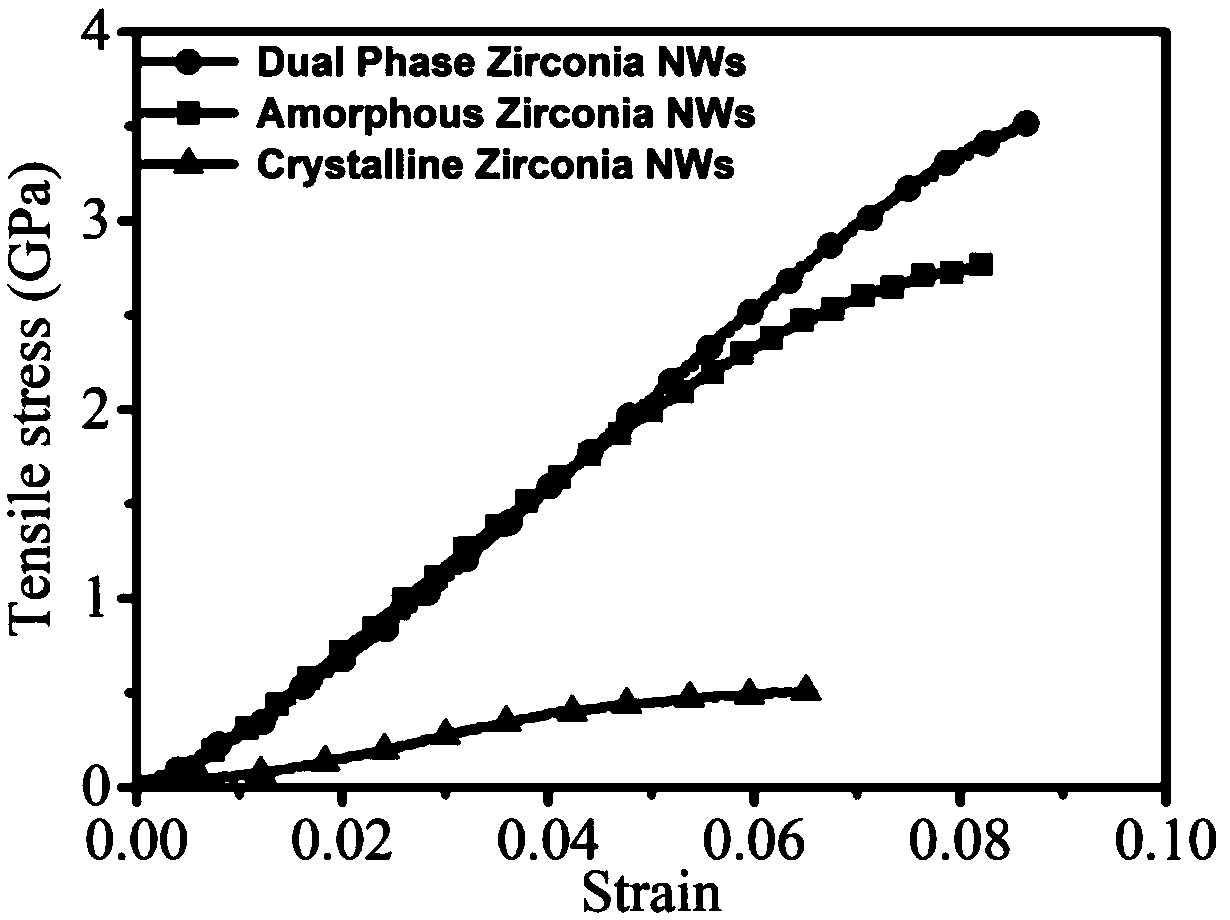

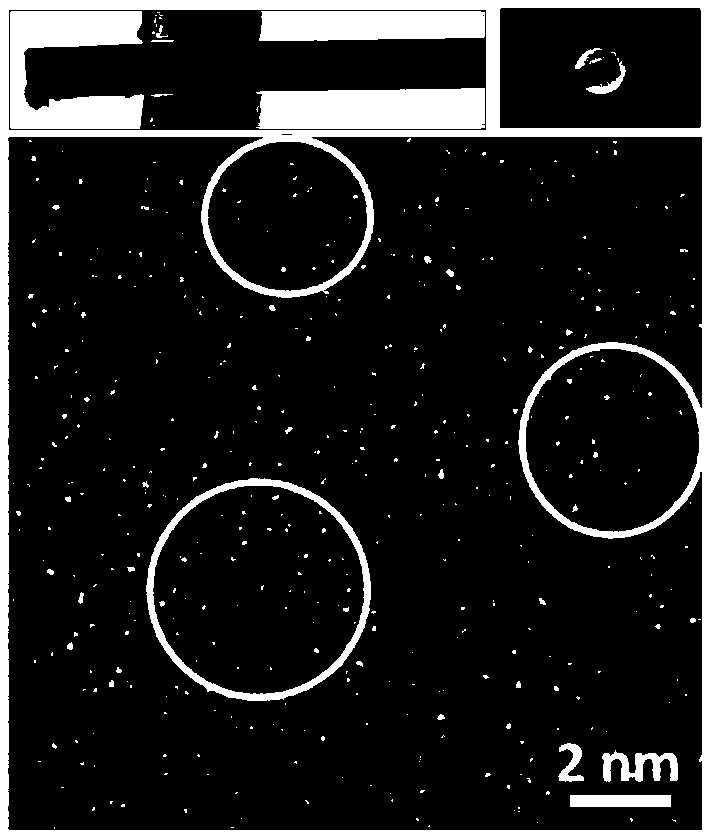

[0028] Preparation method of nanocrystalline reinforced amorphous zirconia nanofiber

[0029] In the first step, prepare an alcohol-water solution (water:ethanol=1:59) at room temperature, stir for 10-30min, and obtain 60-600mL of a colorless and transparent solution that is uniformly mixed;

[0030] In the second step, take 6-60 mL of the solution obtained in the first step, add 0.7 g of polyvinylpyrrolidone, and stir at room temperature for 10 minutes to obtain a uniform colorless and transparent solution;

[0031] In the third step, 10-100 mg of zirconium oxychloride octahydrate was added to the colorless and transparent solution obtained in the second step, and ultrasonically dispersed for 30 minutes to obtain a white suspension solution;

[0032] The fourth step is to keep the white suspension solution obtained in the third step at a constant temperature of 30°C and continue to stir for 2-6 hours. After the solution is cooled to room temperature, it is centrifuged and was...

Embodiment 2

[0036] Preparation method of amorphous zirconia nanofibers

[0037] In the first step, prepare an alcohol-water solution (water:ethanol=2:58) at room temperature, stir for 10-30min, and obtain 60-600mL of a colorless and transparent solution that is uniformly mixed;

[0038] In the second step, take 6-60 mL of the solution obtained in the first step, add 0.5-10 g of polyvinylpyrrolidone, and stir at room temperature for 10 minutes to obtain a uniform colorless and transparent solution;

[0039] In the third step, 10-100 mg of zirconium oxychloride octahydrate was added to the colorless and transparent solution obtained in the second step, and ultrasonically dispersed for 30 minutes to obtain a white suspension solution;

[0040] In the fourth step, keep the white suspension solution obtained in the third step at a constant temperature of 20°C and continue to stir for 2-6 hours. After the solution is cooled to room temperature, it is centrifuged and washed to obtain a white gel...

Embodiment 3

[0044] Preparation method of crystalline zirconia nanofibers

[0045] In the first step, prepare an alcohol-water solution (water:ethanol=3:57) at room temperature, stir for 10-30min, and obtain 60-600mL of a colorless and transparent solution that is uniformly mixed;

[0046] In the second step, take 6-60 mL of the solution obtained in the first step, add 0.5-10 g of polyvinylpyrrolidone, and stir at room temperature for 10 minutes to obtain a uniform colorless and transparent solution;

[0047] In the third step, 10-100 mg of zirconium oxychloride octahydrate was added to the colorless and transparent solution obtained in the second step, and ultrasonically dispersed for 30 minutes to obtain a white suspension solution;

[0048] The fourth step is to keep the white suspension solution obtained in the third step at a constant temperature of 40°C, and continue to stir for 2-6 hours. After the solution is cooled to room temperature, it is centrifuged and washed to obtain a whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com