Negative oxygen ion far infrared tussah silk fiber finishing liquid, negative oxygen ion far infrared tussah silk fiber and preparation method of negative oxygen ion far infrared tussah silk fiber

A technology of negative oxygen ion and fiber finishing, applied in fiber treatment, biochemical fiber treatment, animal fiber, etc., can solve the problem of low generation of negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides the preparation method of the negative oxygen ion far-infrared tussah silk fiber described in the above technical scheme, comprising the following steps:

[0037] The tussah silk fiber is soaked in the negative oxygen ion far-infrared tussah silk fiber finishing solution described in the above technical scheme and then sorted out to obtain the tussah silk fiber after finishing;

[0038] The finished tussah silk fiber is dried to obtain negative oxygen ion far-infrared tussah silk fiber.

[0039] In the present invention, the tussah silk fiber is soaked in the negative oxygen ion far-infrared tussah silk fiber finishing solution described in the above technical proposal and then sorted to obtain the tussah silk fiber after finishing.

[0040] In the present invention, the bath ratio of the tussah silk fiber to the negative oxygen ion far-infrared tussah silk fiber finishing solution is preferably 1:20-50, more preferably 1:30.

[0041...

Embodiment 1

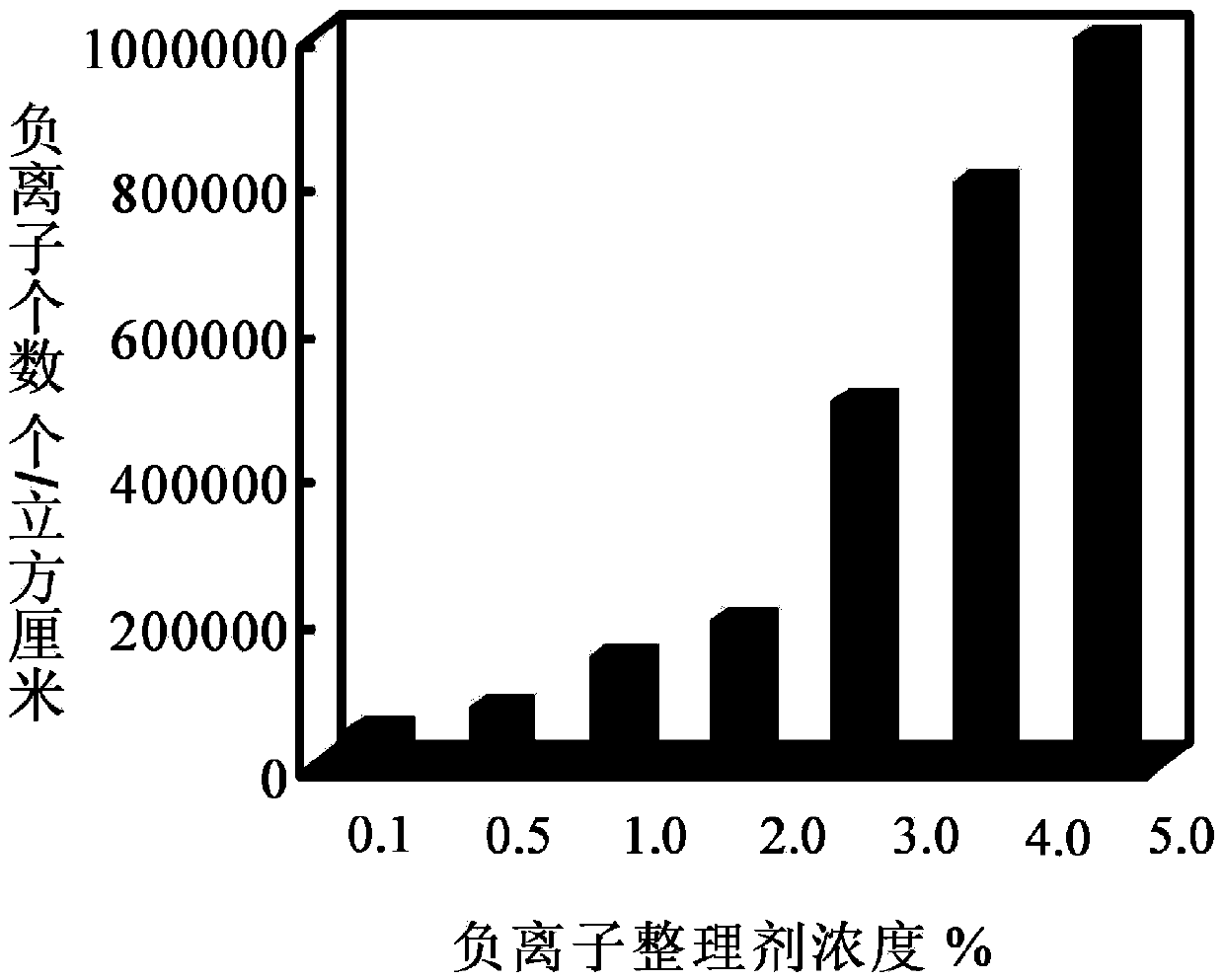

[0047] According to the mass content, the amount of negative ion finishing agent is 0.1, 0.5, 1, 2, 3, 4, 5%, and the other amount is 1% of water-soluble calcium carbide powder, 0.1% of penetrant JFC, 0.1% of chitin, and 0.3% of softener. %, 1% acetic acid, and the rest of water, the raw materials are mixed to obtain negative oxygen ion far-infrared tussah silk fiber finishing liquid.

[0048] Immerse the tussah silk fiber and the finishing solution in the finishing solution according to the bath ratio of 1:30. After soaking for 30 minutes, heat it to 70°C. After finishing for 60 minutes, dry it at 90°C for 10 minutes to obtain negative oxygen ions. Far infrared tussah silk fiber.

[0049] Utilize the negative ion detector to detect the negative oxygen ion generation amount of the oxygen ion far-infrared tussah silk fiber that the present embodiment makes, and the result is as follows figure 1 shown by figure 1 It can be seen that with the increase of the concentration of th...

Embodiment 2

[0059] According to the mass content, the amount of water-soluble calcium carbide powder is 0.1, 0.5, 1, 1.5, 2.0%, and the other amounts are negative ion finishing agent 2.0%, chitin 0.1%, softener 0.3%, acetic acid 1%, penetrant JFC 0.1 %, the rest of the water, the raw materials are mixed to obtain the negative oxygen ion far-infrared tussah silk fiber finishing liquid.

[0060] Immerse the tussah silk fiber and the finishing solution in the finishing solution according to the bath ratio of 1:20. After soaking for 60 minutes, heat it to 70°C. After finishing for 60 minutes, dry it at 90°C for 10 minutes to obtain negative oxygen ions. Far infrared tussah silk fiber.

[0061] Utilize the negative ion detector to detect the negative oxygen ion generation amount of the oxygen ion far-infrared tussah silk fiber that the present embodiment makes, and the result is as follows Figure 4 shown by Figure 4 It can be seen that with the addition of water-soluble calcium carbide pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com