Tunnel excavation support structure for stratum with soft upper part and hard lower part and tunnel excavation construction method

A technology for tunnel excavation and support structures, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of high safety pressure and low construction efficiency, achieve stable force, high construction efficiency, and reduce arch disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

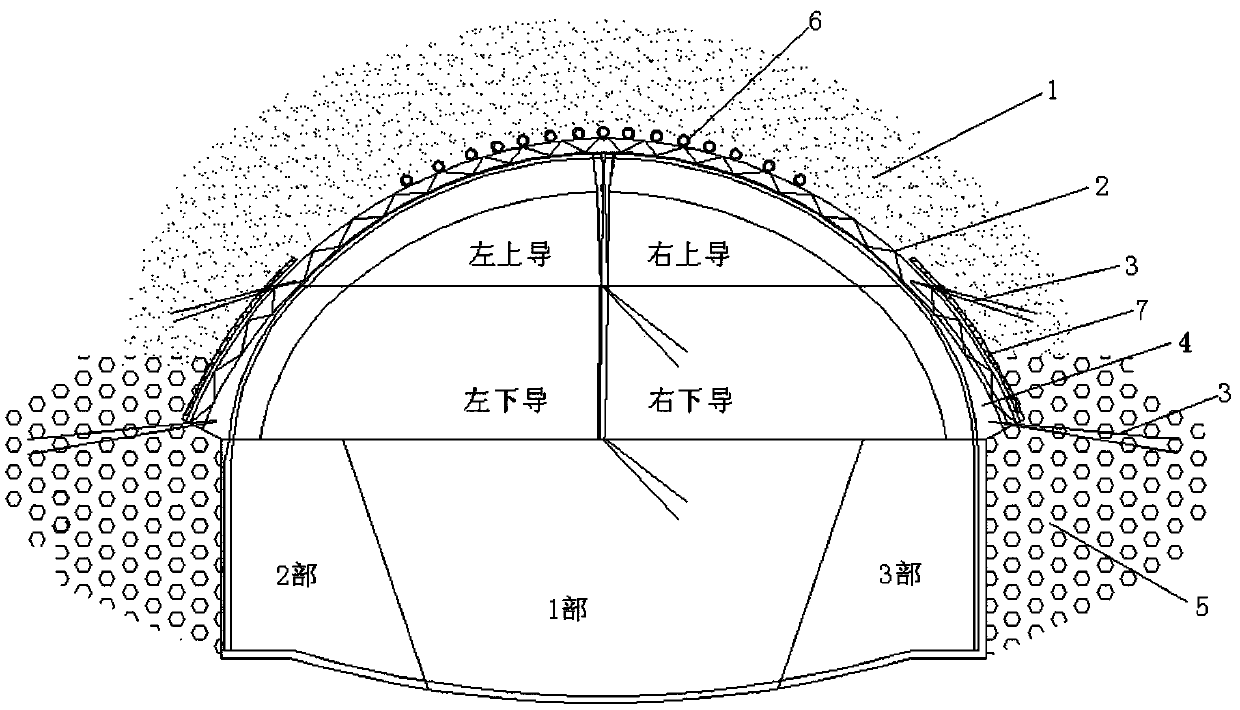

[0020] As shown in the accompanying drawings, an excavation and support structure for tunnels in upper soft and lower hard strata includes an arch cover and hard rock 5 in the lower layer of the tunnel. The arch cover is composed of a plurality of arched steel frames 2, several small conduits 6 and shotcrete layers. The arched steel frames 2 are arranged in sequence along the tunnel direction and connected together. The arches of the arched steel frames 2 After the angle is enlarged, it is fixed on the hard rock 5 in the lower layer of the tunnel. The small conduit 6 is set at the vault and driven into the upper soft stratum 1 of the tunnel, and its tail is welded with the arched steel frame 2. The concrete layer wraps the arched steel frame 2 inside and forms a large arch foot 4 at the arch foot.

[0021] In order to improve the stability of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com