Method for detecting passivation film of cold rolled electroplated tin steel plate

A technology of electroplating tin and passivation film, which is applied in the preparation of test samples, measuring devices, and optical testing of flaws/defects, etc. It can solve the problems of undetectable surface morphology uniformity, improve detection efficiency, and make research intuitive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

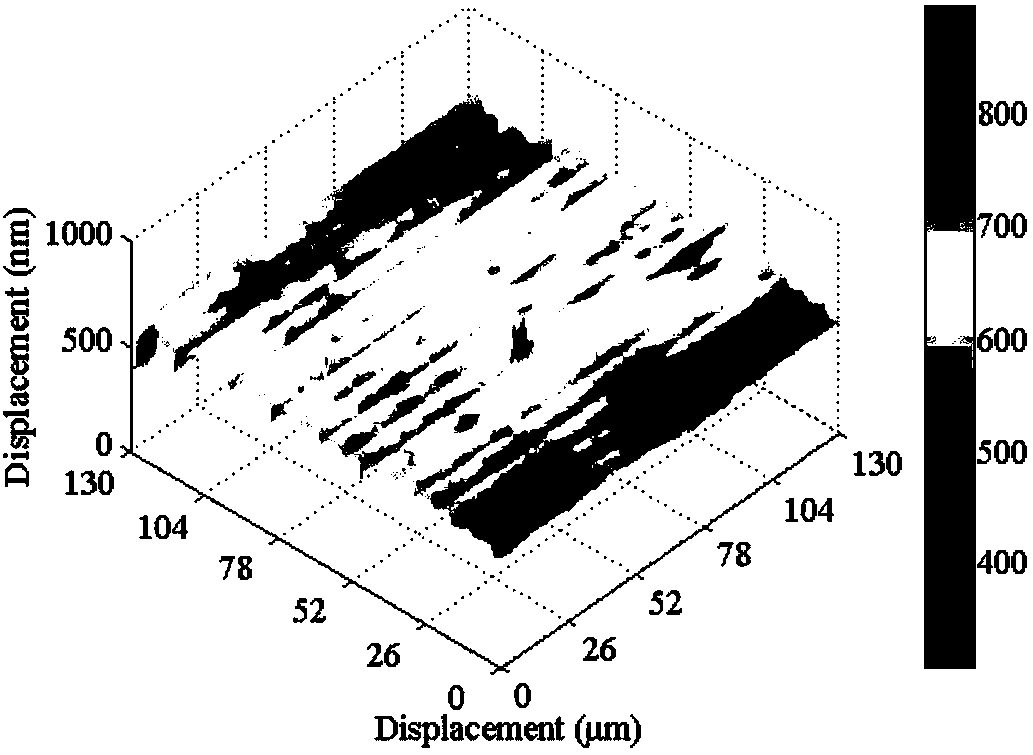

[0024] Example 1, see figure 1 , figure 2 , the thickness of the cold-rolled annealed tin-plated substrate used in Example 1 is 0.2mm, the surface roughness Ra is 0.32um, the yield strength is 356MPa, the tensile strength is 402MPa, and the elongation after fracture is A 50mm 31%;

[0025] A method for detecting a passivation film on a cold-rolled electrotinned steel plate, the method comprising the following steps:

[0026] 1) Prepare the basic sample, and cut the cold-rolled annealed tin-plated substrate with a clean surface of 10mm×15mm as the basic sample;

[0027] 2) Electrotinning is performed on the basic sample to obtain an electro-tinned steel plate, and the electro-tinned steel plate is cut into 3 templates of 10 mm × 5 mm, which are respectively marked as sample 1, sample 2 and sample 3, and the electro-tinned steel plate is The thickness of the tin layer is 0.5g / dm 2 , the surface roughness Ra is 0.022um, and the tin electroplating step includes, the electropl...

Embodiment 2

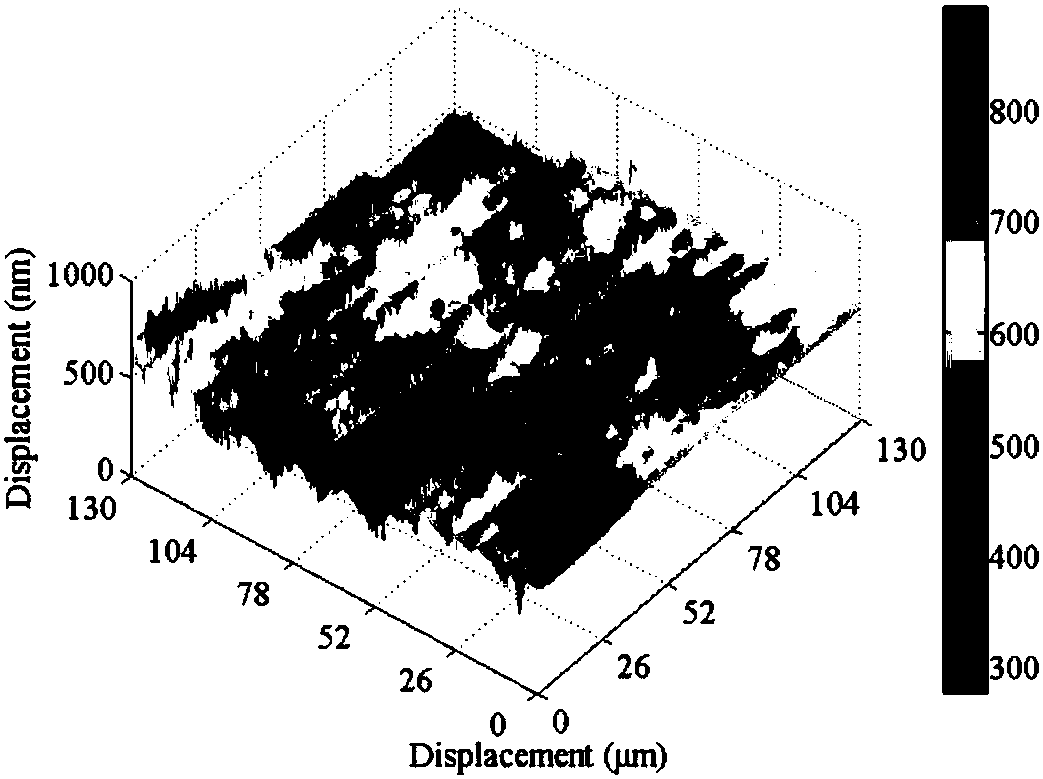

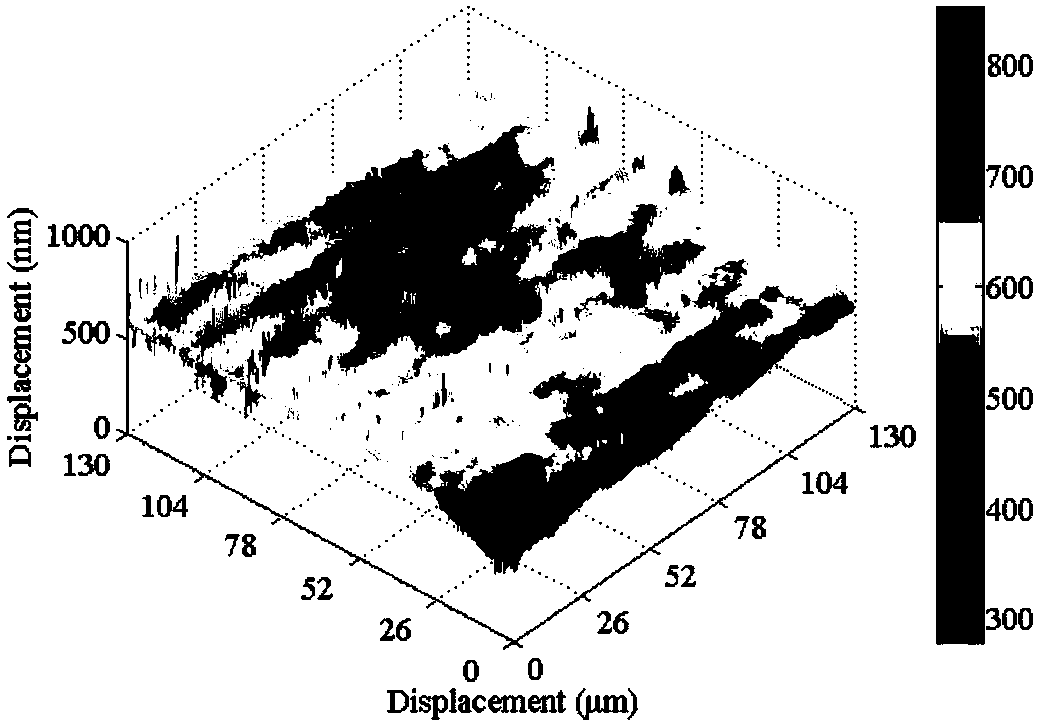

[0031] Example 2, see figure 1 , image 3 , The cold-rolled annealed tin-plated substrate used in embodiment 2 is the same as embodiment 1.

[0032] A method for detecting passive film on cold-rolled tin-plated steel plate, the method comprises the following steps, step 1), step 2), step 1), step 2) and step 1) and step 2) described in Example 1 Same; also includes:

[0033] 3) Perform electrochemical passivation on sample 3, immerse sample 3 in a sodium dichromate solution with a temperature of 45° C., a concentration of 30 g / L, and a pH value of 4.4 for cathodic electrochemical passivation. Sample 3 is Cathode with a current density of 1A / dm 2 , take out sample 3 after passivation for 6s, rinse sample 3 with water and dry it;

[0034] 4) Measure sample 1 and sample 3 after passivation treatment by using a three-dimensional optical surface profiler, the measurement method is the same as the method in step 4) described in Example 1, and the average value of roughness of samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com