Solid rocket motor cold test run test system

A test system and solid rocket technology, applied in the field of solid rocket motor cold test, can solve the problems of low safety and affect the authenticity of the test, and achieve the effects of high safety, avoiding the problem of friction and heat generation, and high test authenticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

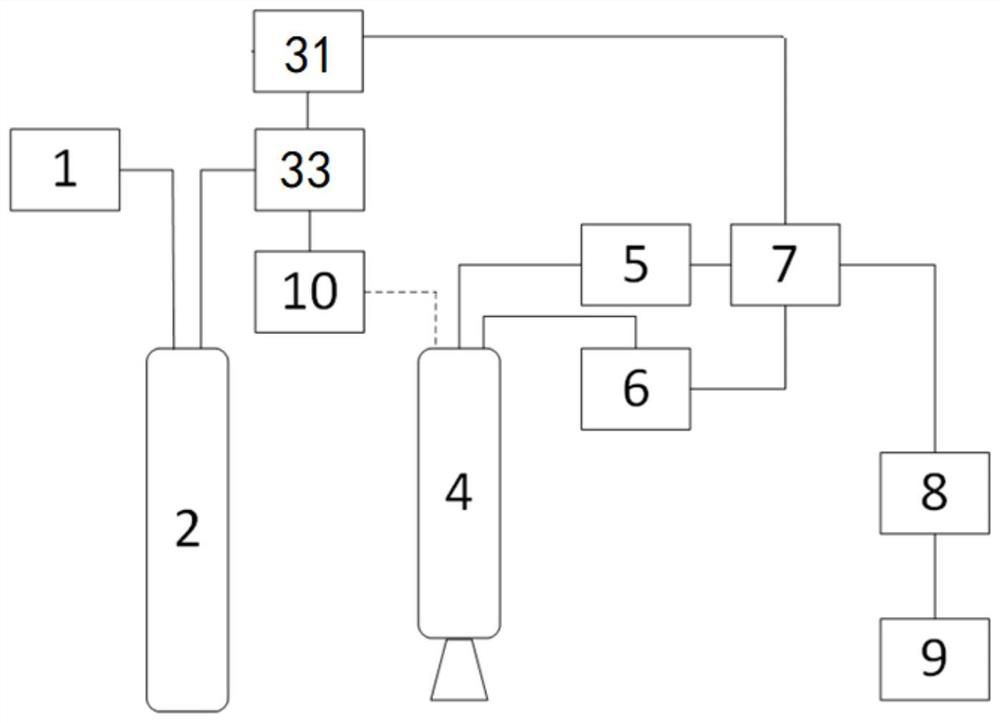

[0023] This embodiment provides a solid rocket motor cold test run test system, which changes the working medium in contact with the charge from gas to liquid, and meets the requirements of the boosting rate of the engine combustion chamber through the cooperation of the gas circuit and the oil circuit.

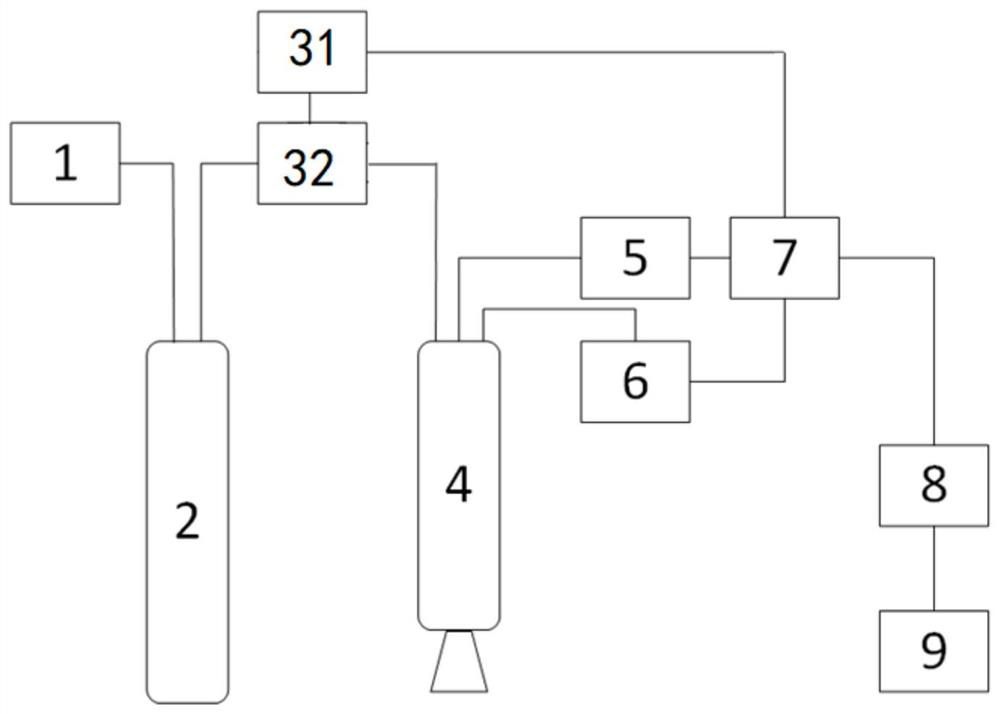

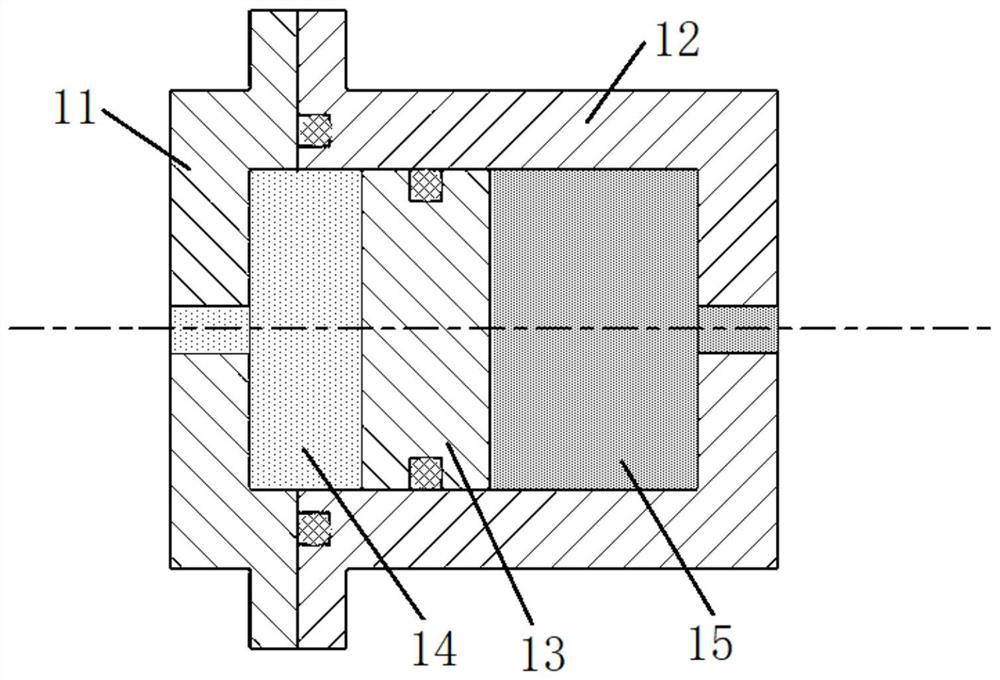

[0024] Such as figure 2 As shown, the solid rocket motor cold test system includes: air source controller 1, pressure tank 2, test pressure controller 31, engine 4, pressure sensor 5, strain tester 6, amplification exchange interface 7, computer 8, printer 9 And air / hydraulic pressure transmitter 10. This scheme is applied to the traditional solid rocket motor cold pressurization test system ( figure 1 ), an air / hydraulic pressure transmitter 10 is added between the pressure tank 2 and the engine 4, and the gas / hydraulic pressure transmitter 10 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com