Main oscillation power amplifier structure-based pulse fiber laser

A technology for power amplifiers and fiber lasers, applied in the direction of lasers, laser components, and the structure/shape of active media, can solve the problems of pulse power loss, lack of mature and stable commercial devices, etc., and achieve easy adjustment and insensitive wavelength stability , the effect of small insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

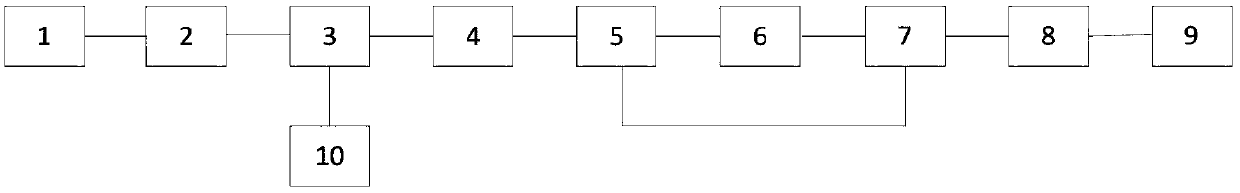

[0020] Such as figure 1 As shown, this embodiment provides a pulsed fiber laser based on a main oscillator power amplifier structure, including a pulsed seed light source 1, a first isolator 2, a first wavelength division multiplexer 3, and a first doped fiber 4 , a second wavelength division multiplexer 5, a second doped fiber 6, a third wavelength division multiplexer 7, a third doped fiber 8, a second isolator 9 and a single-mode pump laser 10;

[0021]Specifically, the output end of the pulsed seed light source 1 is connected to the input end of the first isolator 2, and the output end of the first isolator 2 is connected to the signal end of the first wavelength division multiplexer 3, and the first wave The pump end of the division multiplexer 3 is connected to the output end of the single-mode pump laser 10, and the common end of the first wavelength division multiplexer 3 is connected to the input end of the first doped fiber 4, and the first doped fiber The output en...

Embodiment 2

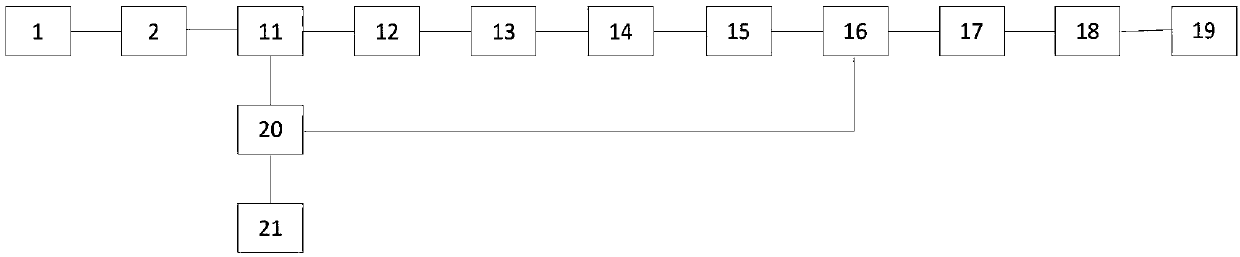

[0030] Such as figure 2 As shown, this embodiment provides a pulsed fiber laser based on a main oscillator power amplifier structure, and the main difference from the above-mentioned embodiment 1 is that the pump laser in this embodiment is a multi-mode pump laser 21;

[0031] Specifically, the pulsed fiber laser of this embodiment includes a pulsed seed light source 1, a first isolator 2, a first multimode pump combiner 11, a fourth doped fiber 12, a first pump stripper 13, a first Multimode isolator 14, fifth doped fiber 15, second multimode pump combiner 16, sixth doped fiber 17, second pump stripper 18, second multimode isolator 19, multimode pump A pump splitter 20 and a multimode pump laser 21;

[0032] Specifically, the output end of the pulsed seed light source 1 is connected to the input end of the first isolator 2, and the output end of the first isolator 2 is connected to the signal end of the first multimode pump combiner 11, and the first The pump end of the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com