A temperature-responsive flame-retardant film and its preparation method and application

A flame-retardant film, temperature-responsive technology, applied in thermometers, thermometers using electrical/magnetic components directly sensitive to heat, and electrical devices, etc., can solve the problems of graphene oxide being easy to burn and unable to work continuously for a long time. , to achieve the effects of sensitive temperature responsiveness, overcoming easy combustion consumption, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Dissolve 125mg of polyethylene glycol in 50mL of deionized water to obtain a polyethylene glycol solution. After stirring evenly, add 125mg of montmorillonite, and after stirring for 1h, add 11.12mL of graphene oxide (11.24mg mL -1 ), after stirring for 3 hours, adding 0.25mL of tannic acid aqueous solution with a concentration of 5% by weight to obtain a flame retardant coating mixture, and finally vacuumizing the resulting flame retardant coating mixture, and drying it at 50°C, namely A temperature-responsive flame-retardant film (PMG) was obtained.

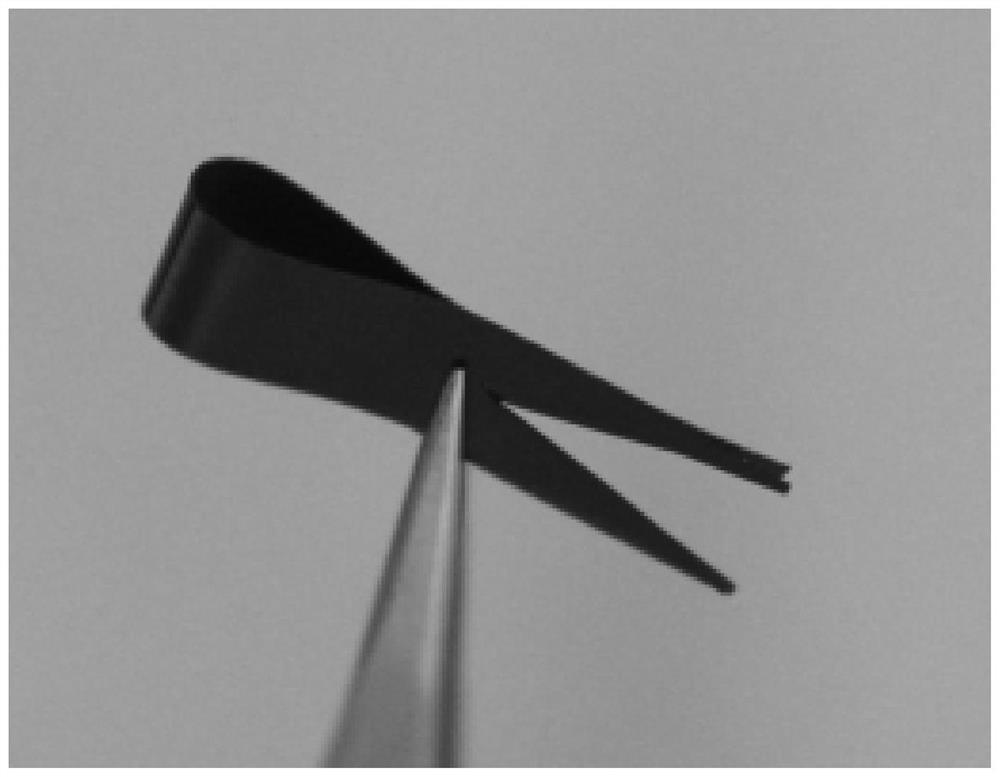

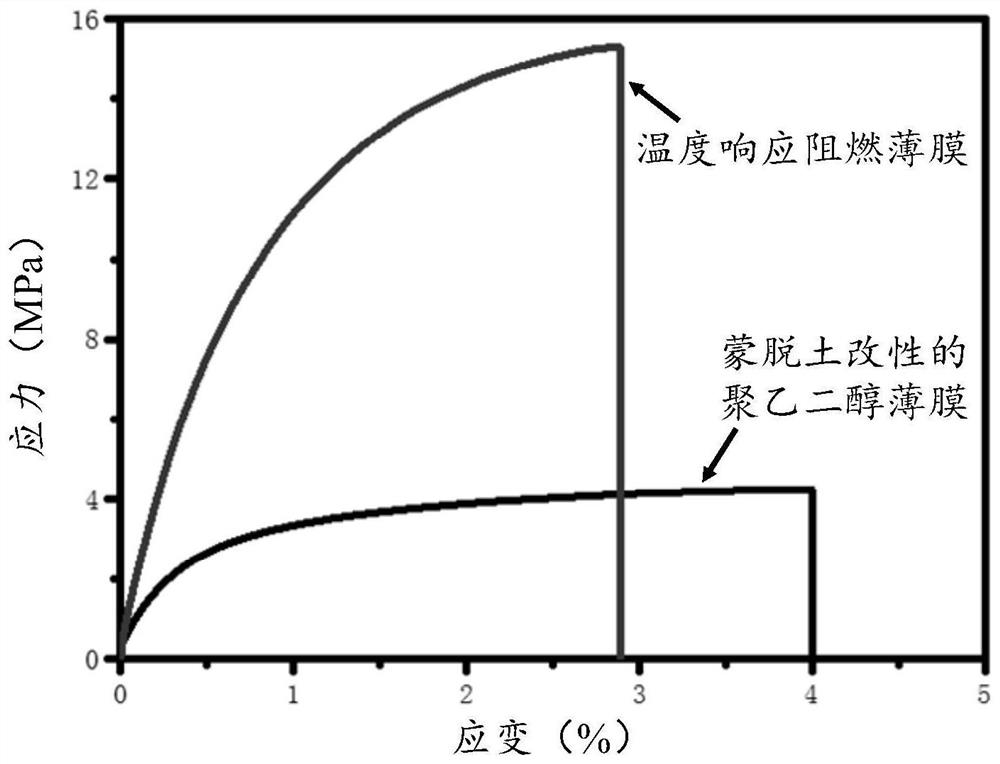

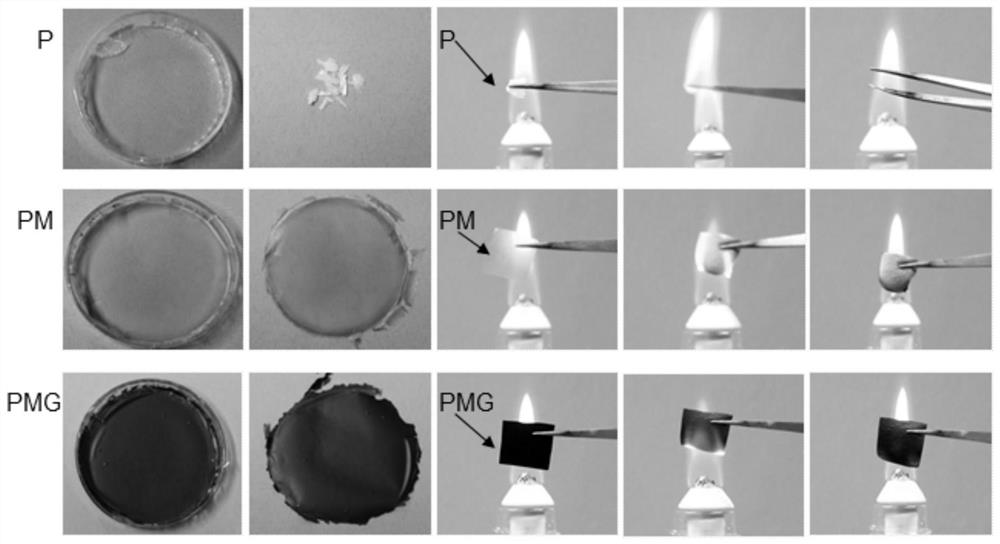

[0069] The PMG prepared in embodiment 1 is bent and folded with tweezers, such as figure 1 As shown, it can be seen that the PMG prepared in Example 1 can be bent and folded, indicating that the temperature-responsive flame-retardant film of the present invention exhibits moderate mechanical interference to the outside world and has good mechanical elasticity. The usual unavoidable bending, compression and impact will n...

Embodiment 2

[0077] Dissolve 125mg of polyethylene glycol in 50mL of deionized water to obtain a polyethylene glycol solution. After stirring evenly, add 125mg of montmorillonite, and after stirring for 1h, add 1.11mL of graphene oxide (11.24mg mL -1 ), after stirring for 3 hours, 0.1 mL of glutaraldehyde was added to obtain a flame-retardant coating mixture, and finally the obtained flame-retardant coating mixture was vacuumized to remove air bubbles, and dried at 50°C to obtain a temperature-responsive flame-retardant film.

Embodiment 3

[0079] Dissolve 125mg of polyethylene glycol in 50mL of deionized water to obtain a polyethylene glycol solution. After stirring evenly, add 62.5mg of montmorillonite. After stirring, sonicate for 1.5h, add 5.56mL of graphene oxide (11.24mg mL -1 ), after stirring for 2.5 hours, adding 0.2mL of tannic acid aqueous solution with a concentration of 10% by weight to obtain a flame retardant coating mixture, and finally vacuumizing the resulting flame retardant coating mixture, and drying it at 60°C. That is, a temperature-responsive flame-retardant film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com