A kind of surface modification method of aramid fiber

A kind of aramid fiber and surface modification technology, which is applied in the surface modification of aramid fiber, in the field of synergistic modification of the surface of aramid fiber by hyperbranched polysiloxane and graphene oxide, which can solve problems such as unfavorable graphene. , to achieve the effect of improving the tensile strength of monofilament, enhancing the bonding strength, and the potential of large industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

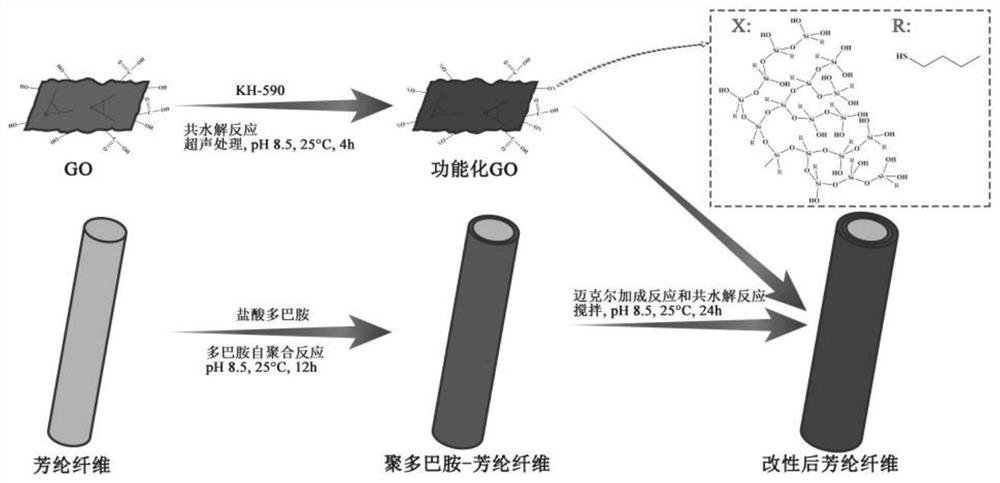

[0037] Such as figure 1As shown, the surface modification methods of aramid fibers include:

[0038] Step 1: cleaning and drying of the surface of the aramid fiber;

[0039] Step 2: pretreatment of the surface of the aramid fiber;

[0040] Step 3: functionalization of graphene oxide GO;

[0041] Step 4: Synergistic modification of hyperbranched polysiloxane and graphene oxide GO.

[0042] The cleaning and drying of the surface of the aramid fiber includes: washing the aramid fiber with ethyl acetate and acetone in turn to obtain the cleaned aramid fiber, and then placing the cleaned aramid fiber in a vacuum oven at a temperature of 100°C Drying under conditions until the dried aramid fiber is obtained.

[0043] The frequency of washing the aramid fibers alternately with ethyl acetate and acetone is 5 times.

[0044] The pretreatment of the surface of the aramid fiber includes: immersing the dried aramid fiber in a 2g / L dopamine hydrochloride solution, the dopamine hydroch...

Embodiment 2

[0067] Surface modification methods of aramid fibers, including:

[0068] Step 1: cleaning and drying of the surface of the aramid fiber;

[0069] Step 2: pretreatment of the surface of the aramid fiber;

[0070] Step 3: functionalization of graphene oxide GO;

[0071] Step 4: Synergistic modification of hyperbranched polysiloxane and graphene oxide GO.

[0072] The cleaning and drying of the surface of the aramid fiber includes: washing the aramid fiber with ethyl acetate and acetone in turn to obtain the cleaned aramid fiber, and then placing the cleaned aramid fiber in a vacuum oven at a temperature of 100°C Drying under conditions until the dried aramid fiber is obtained.

[0073] The frequency of washing the aramid fiber with ethyl acetate and acetone in turn is 8 times.

[0074] The pretreatment of the surface of the aramid fiber includes: immersing the dried aramid fiber in a 2g / L dopamine hydrochloride solution, the dopamine hydrochloride solution is adjusted to a ...

Embodiment 3

[0091] Surface modification methods of aramid fibers, including:

[0092] Step 1: cleaning and drying of the surface of the aramid fiber;

[0093] Step 2: pretreatment of the surface of the aramid fiber;

[0094] Step 3: functionalization of graphene oxide GO;

[0095] Step 4: Synergistic modification of hyperbranched polysiloxane and graphene oxide GO.

[0096] The cleaning and drying of the surface of the aramid fiber includes: washing the aramid fiber with ethyl acetate and acetone in turn to obtain the cleaned aramid fiber, and then placing the cleaned aramid fiber in a vacuum oven at a temperature of 100°C Drying under conditions until the dried aramid fiber is obtained.

[0097] The frequency of washing the aramid fiber with ethyl acetate and acetone alternately is 10 times.

[0098] The pretreatment of the surface of the aramid fiber includes: immersing the dried aramid fiber in a 2g / L dopamine hydrochloride solution, the dopamine hydrochloride solution is adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com