Femtosecond laser etching based sapphire fiber Fabry-Perot sensor and manufacturing method thereof

A Fa-Per sensor and femtosecond laser technology, which is applied in the field of miniaturized sapphire fiber high-temperature sensors, can solve the problems of reduced radiation power at low temperature, limited temperature measurement range, low measurement accuracy, etc., and achieves strong environmental adaptability and economic benefits. , The effect of optimizing the optical path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

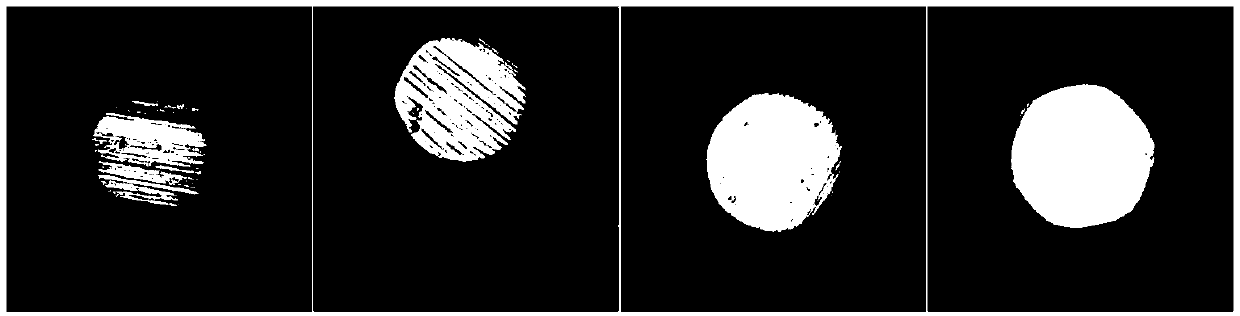

Image

Examples

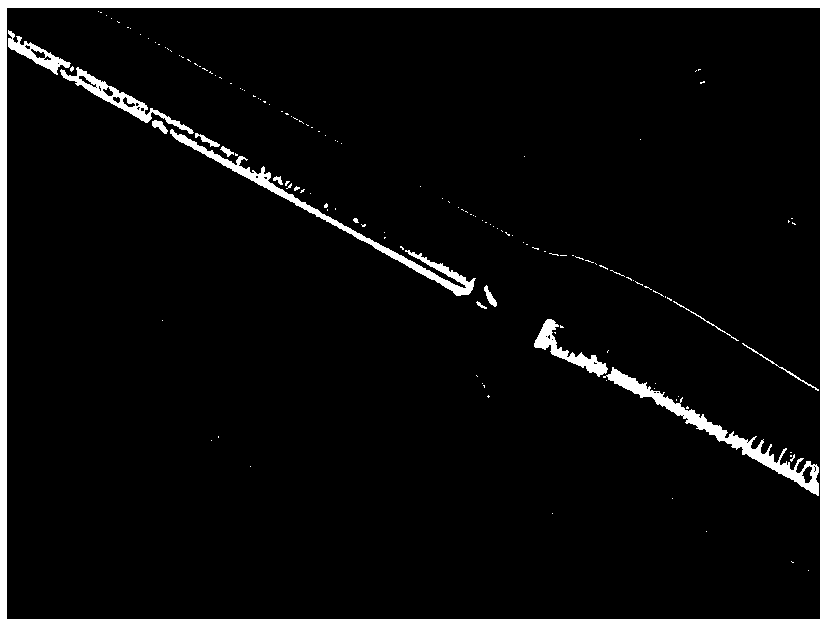

Embodiment 1

[0029] combine Figure 4 and Image 6 As shown, the original signal 10 from the 850nm LED broadband light source 9 is introduced into the Fabron microcavity 2 through the optical fiber jumper 7, the multimode quartz optical fiber 5, the heterogeneous optical fiber fusion splicing point 6, and the sapphire optical fiber 1, and the interference signal 11 light passes through in turn The sapphire optical fiber 1 , the heterogeneous optical fiber fusion splicing point 6 , the quartz optical fiber 5 , and the optical fiber jumper 7 are received by a spectrometer 12 . The high temperature sensor is placed in the tubular cavity of the high temperature muffle furnace 13, and a temperature variable is applied to the sensor by adjusting the temperature in the muffle furnace cavity, and the measurement range is 100-1080°C. The change of temperature causes the optical refractive index of the Faper microcavity 2 and the expansion and contraction of the material, which causes the change of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com