A solder paste printing performance influence factor analysis method based on SMT big data

A technology of solder paste printing and influencing factors, which is applied in the field of analysis of influencing factors of solder paste printing performance based on SMT big data, can solve problems such as surface mount product quality problems, unsuitable test design factor level selection, and affecting enterprise benefits, etc. Achieve the effect of ensuring model output results, good model output results, and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At present, the methods for analyzing the influencing factors of solder paste printing performance mainly include production experience, experimental design, statistical methods and data mining. Most of them select a range of influencing factors based on experience, and then conduct quantitative analysis to judge their degree of influence and interaction. The analysis method used is costly and time-consuming. At the same time, the data mining method using fitting relational expressions is too subjective, and it is difficult to objectively and accurately reflect the complex relationship between solder paste printing performance indicators and printing parameters. At the same time, it is difficult for existing models to simultaneously Incorporating numerical and categorical printing parameter characteristics into the analysis process of influencing factors, some important parameters that affect the printing performance of solder paste are omitted.

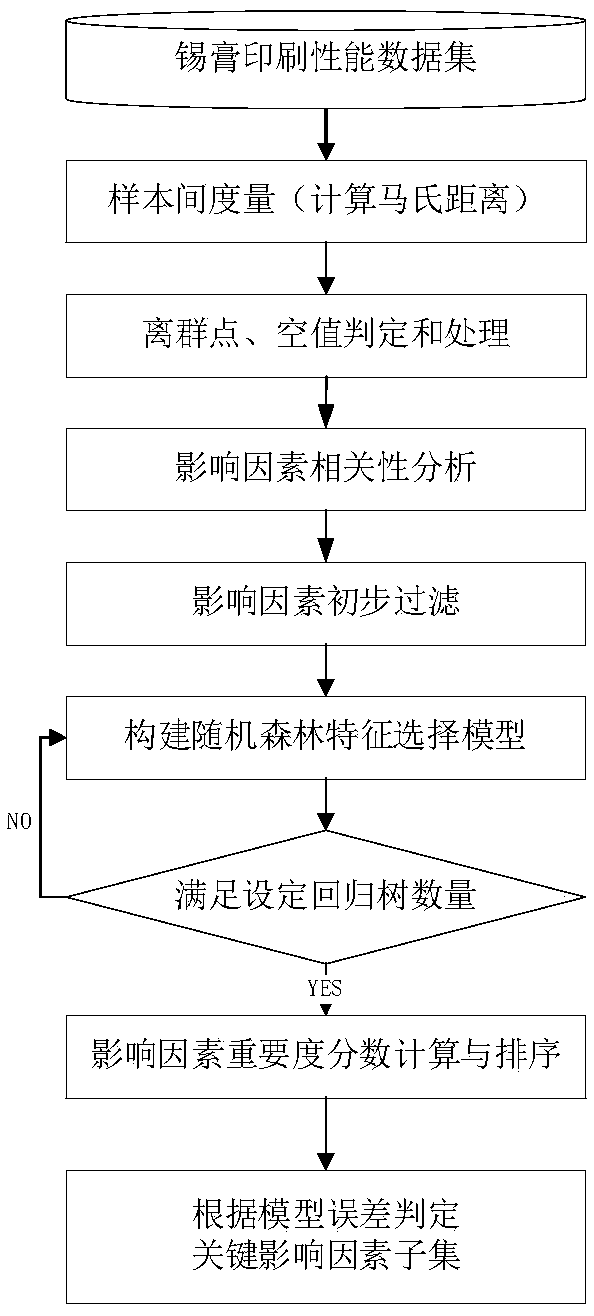

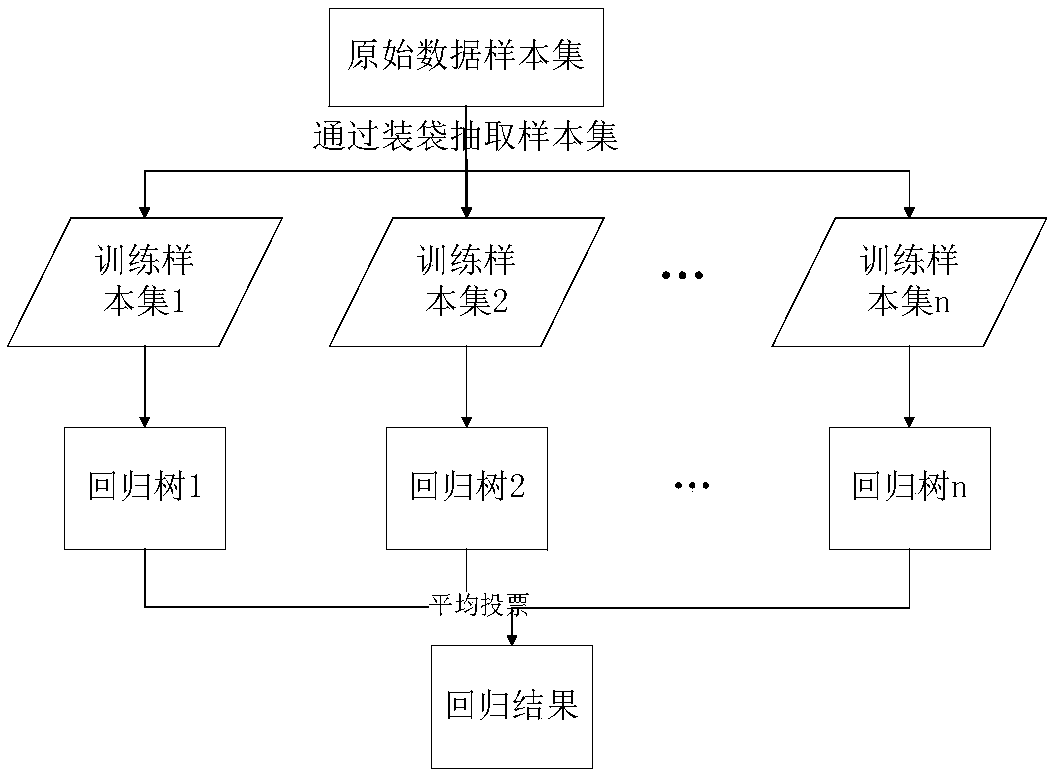

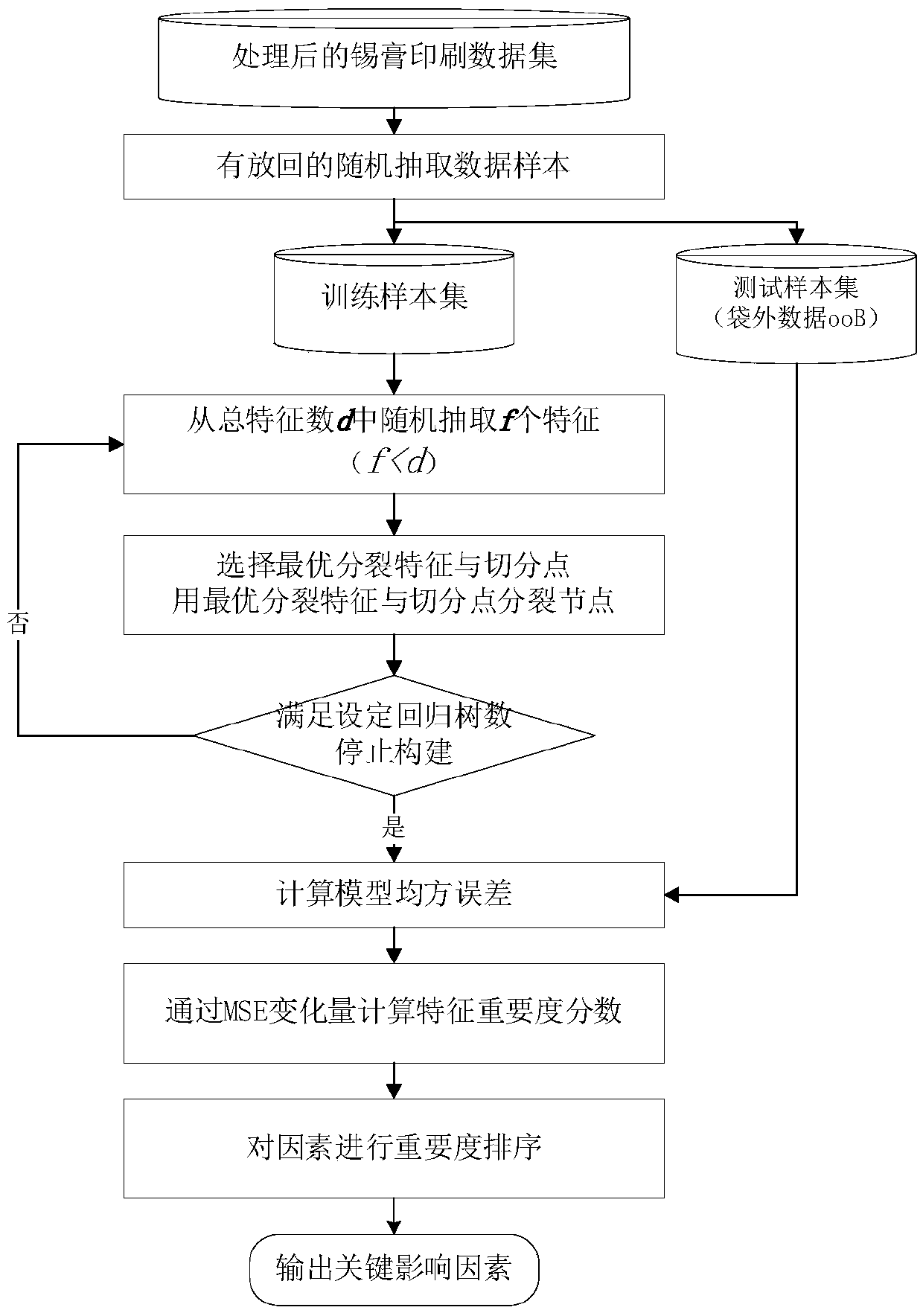

[0032]The present inve...

Embodiment 2

[0043] The analysis method of influencing factors of solder paste printing performance based on SMT big data is the same as embodiment 1, and the outlier detection based on the Mahalanobis distance between data samples described in step (2) of the present invention is by calculating the Mahalanobis distance between data sample points To test the proximity between samples, its advantage over Euclidean distance is that Mahalanobis distance will consider the shape of the distribution instead of just calculating the distance from the point to the center of the distribution. For example, for the data attribute of an elliptical distribution, although the point near the short side is closer to the center of the distribution, it may deviate more from the overall distribution shape area.

[0044] For the row vectors x and y composed of two different data samples in the solder paste printing data set X, the Mahalanobis distance is calculated as follows:

[0045]

[0046] where d repr...

Embodiment 3

[0052] The analysis method of influencing factors of solder paste printing performance based on SMT big data is the same as that of Embodiment 1-2, and the correlation between the calculation factors described in step (3) of the present invention includes three ways: numerical and numerical printing parameter characteristics The calculation of the correlation between the numerical and category printing parameter features and the Clem correlation coefficient calculation between the category printing parameter features. There are different calculation methods for different attribute correlation calculations. The specific calculations are as follows:

[0053] (3.1) Calculate the correlation coefficient

[0054] The correlation coefficient can be used to measure the degree of correlation between numerical data attributes. For two printing parameter features x and y, the calculation formula of the correlation coefficient is as follows:

[0055]

[0056] Among them, r x,y Indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com