Semiconductor structures and methods of forming them

A technology of semiconductor and gate structure, applied in the field of semiconductor structure and its formation, can solve problems such as serious gate-induced drain leakage current, and achieve the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As described in the background, the gate-induced drain leakage current of the semiconductor device is serious.

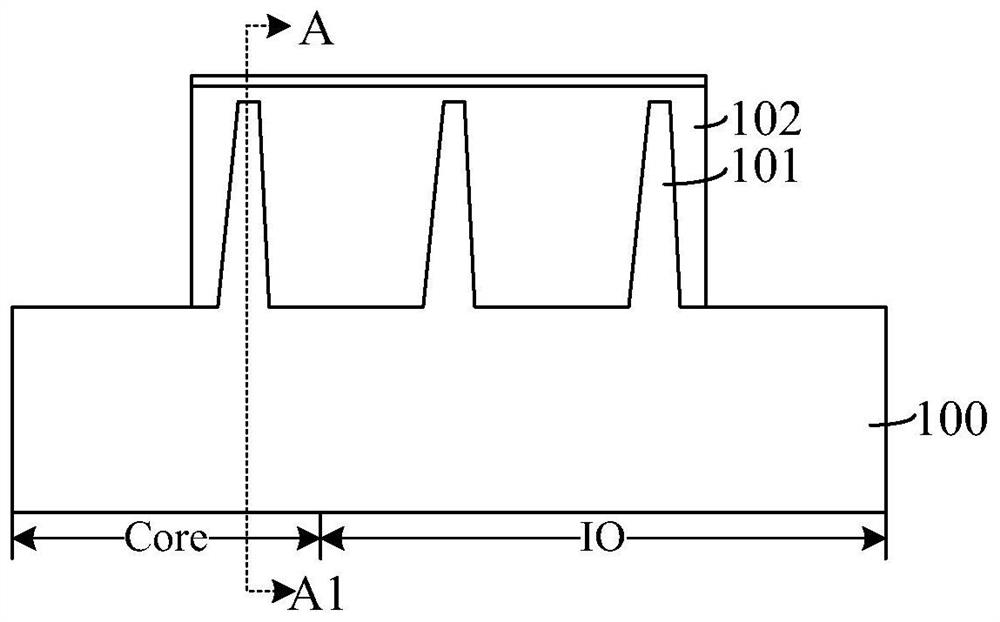

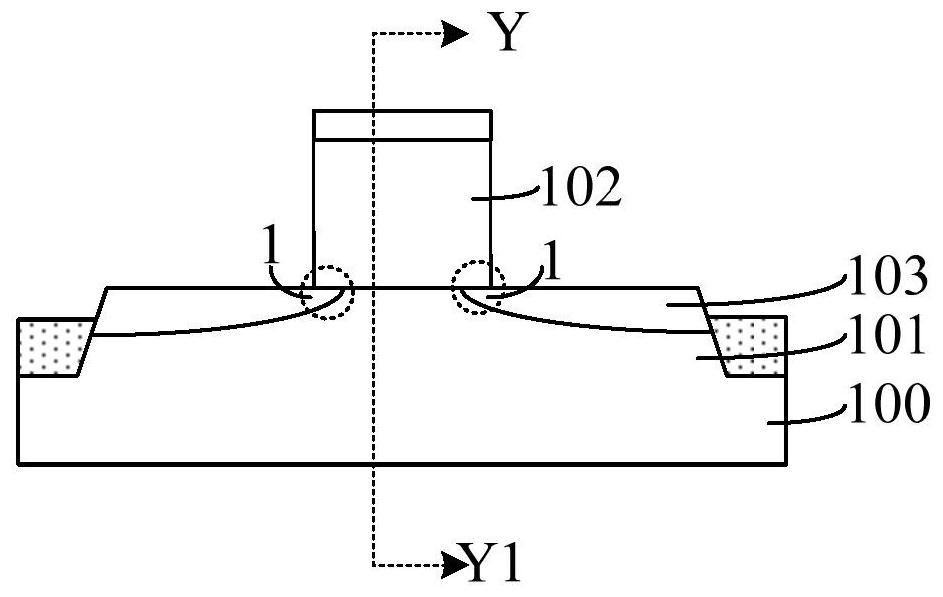

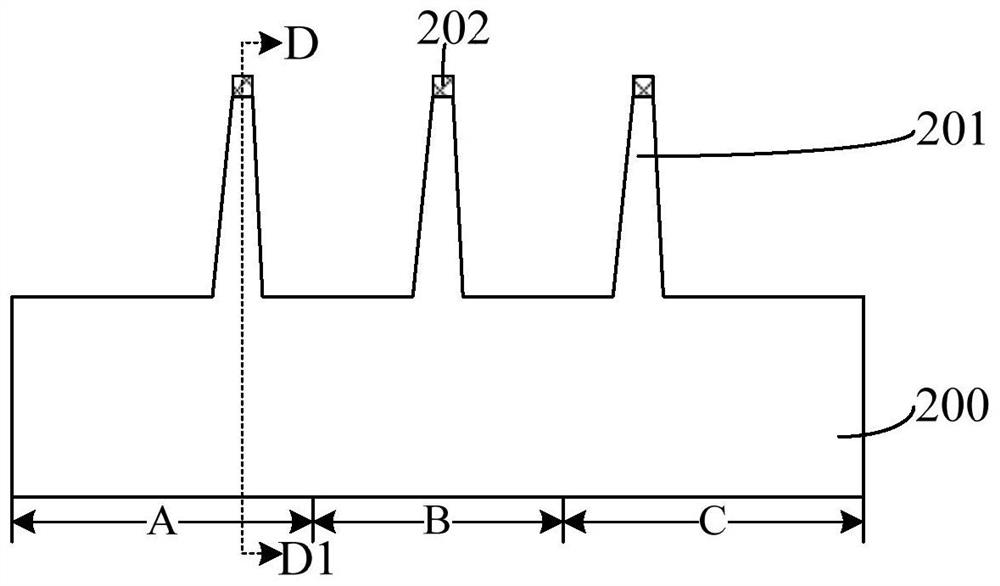

[0033] figure 1 with figure 2 A schematic diagram of a semiconductor structure.

[0034] Please refer to figure 1 with figure 2 , figure 2 yes figure 1 A schematic sectional view along line AA1, figure 1 yes figure 2 A schematic cross-sectional view along the Y-Y1 line, a substrate 100, the substrate 100 includes a Core region and an IO region, the Core region and the IO region respectively have several fins 101 on the substrate 100; a gate structure 102 across the fins 101 ; The source and drain doped regions 103 in the fin portion 101 located on both sides of the gate structure 102 .

[0035]In the above method, since the step of forming the source-drain doped region 103 includes: forming a source-drain opening in the fin portion 101 on both sides of the gate structure 102; forming an epitaxial layer in the source-drain opening; Doping ions int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com