Steam system with automatic water supply and drainage functions, control method and steamer

A technology of automatic water replenishment and steam system, applied in the field of steamers with this series of functions, can solve the problems affecting the health of steamed food and the growth of bacteria, so as to ensure the cooking effect of food, fast response speed, saving manufacturing cost and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

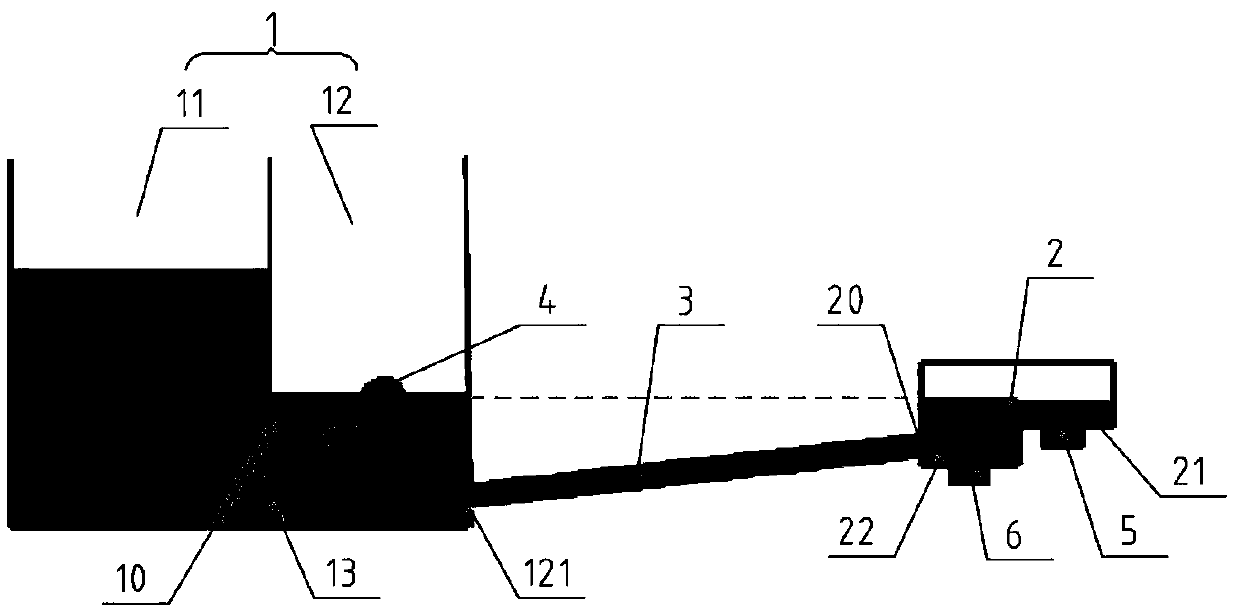

[0040] Such as figure 1 As shown, a steam system with automatic water supply and drainage function in this embodiment includes a water tank 1 , an evaporation pan 2 , a water pipe 3 , a valve body 4 , a temperature sensor 5 and a temperature controller 6 . The evaporator 2 and the water tank 1 are connected through the water pipe 3 , and the bottom of the evaporator 2 is set higher than the connection between the water tank 1 and the water pipe 3 . Thus, the evaporator 2 and the water tank 1 form the principle of an inverted siphon. When the water tank 1 is filled with sufficient water, the water tank 1 and the evaporator 2 can maintain the same water level, thereby realizing automatic replenishment of the evaporator 2, saving The water pump used for replenishing water and the water level sensor used to detect the water level of the water tank are eliminated, thereby reducing manufacturing and use costs. When the remaining water in the water tank 1 is discharged, the remainin...

Embodiment 2

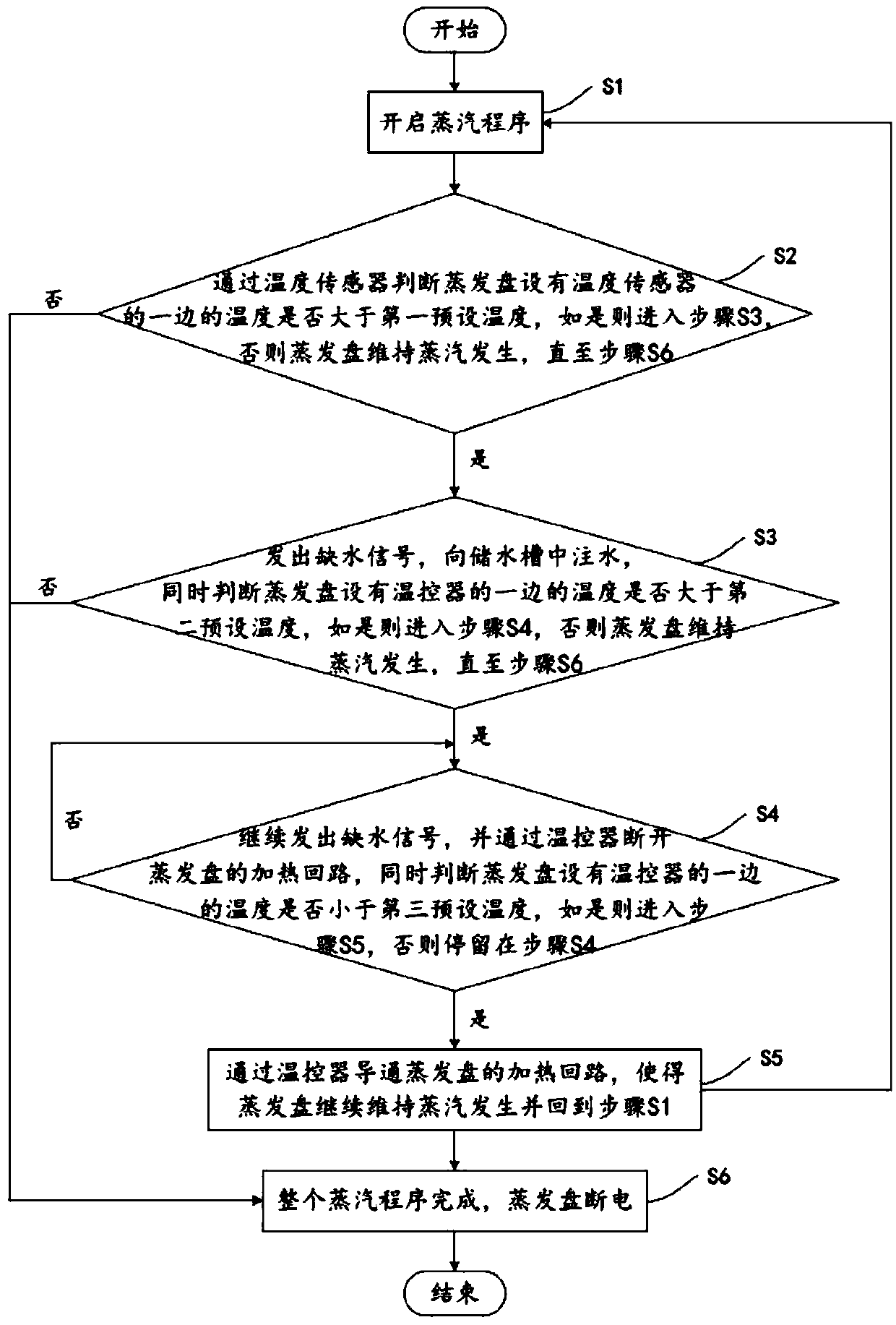

[0049] Such as image 3 As shown, the control method of this embodiment, which uses a steam system with automatic water replenishment and drainage functions as described in Embodiment 1, includes the following steps:

[0050] S1: Turn on the steam program; thus, the heating circuit of the evaporator 2 is turned on, and the water level in the evaporator 2 continues to drop as the steam program runs;

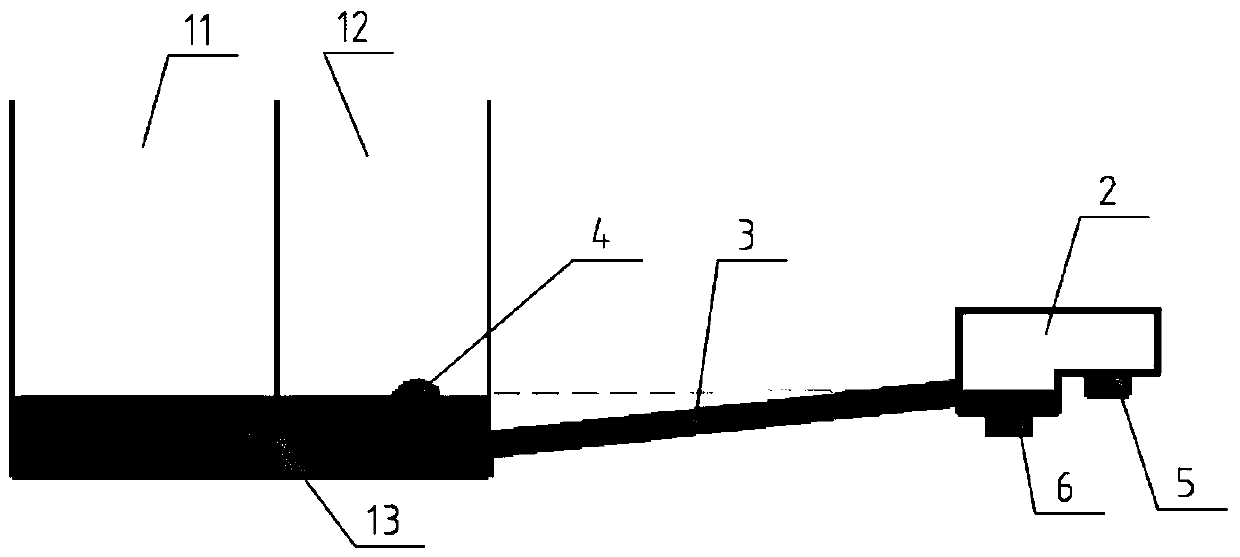

[0051] S2: Use the temperature sensor 5 to judge whether the temperature of the side of the evaporator 2 provided with the temperature sensor 5 is greater than the first preset temperature, if so, enter step S3, otherwise the evaporator 2 maintains steam generation until step S6; when the evaporator 2 When the water in the evaporator continues to decrease until there is no water on the right side of the evaporator 2, there is water on the left side of the evaporator 2, such as figure 2 As shown, the temperature on the right side of the evaporating tray 2 rises to be greater than...

Embodiment 3

[0066] This embodiment provides a steamer, which has a steam system with automatic water replenishment and drainage function as described in Embodiment 1 or applies the control method as described in Embodiment 2. It has a simple structure and has an automatic water replenishment and drainage function. The control method is safe and the response is fast. When there is water shortage in the steam system during the cooking process, a water shortage signal can be sent in advance and the steam program can be maintained, and water can be automatically replenished to the evaporator 2 without opening the cabinet door to ensure uninterrupted steam generation. At the same time, when water supply to the evaporator 2 fails or is not timely, the heating circuit of the evaporator 2 can be automatically disconnected to prevent dry burning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com