A Shaftless Polishing Equipment for Mat Bamboo Chips and Its Application Method

A bamboo chip and shaftless technology, which is applied in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve problems such as wasting labor, reducing heating efficiency, and damage to mats, and achieves improved grinding Efficiency and quality, increase the heating area, avoid the effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

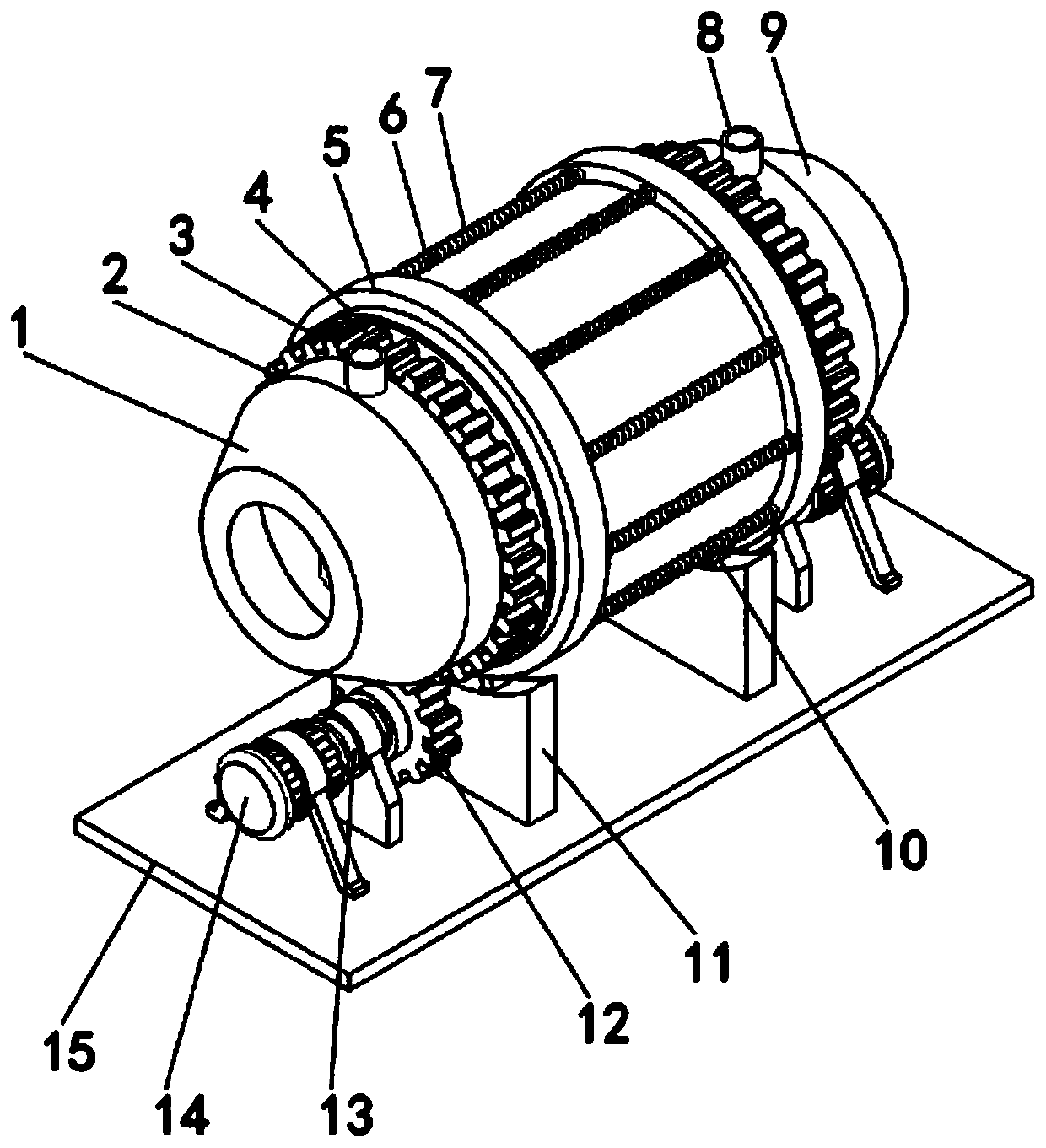

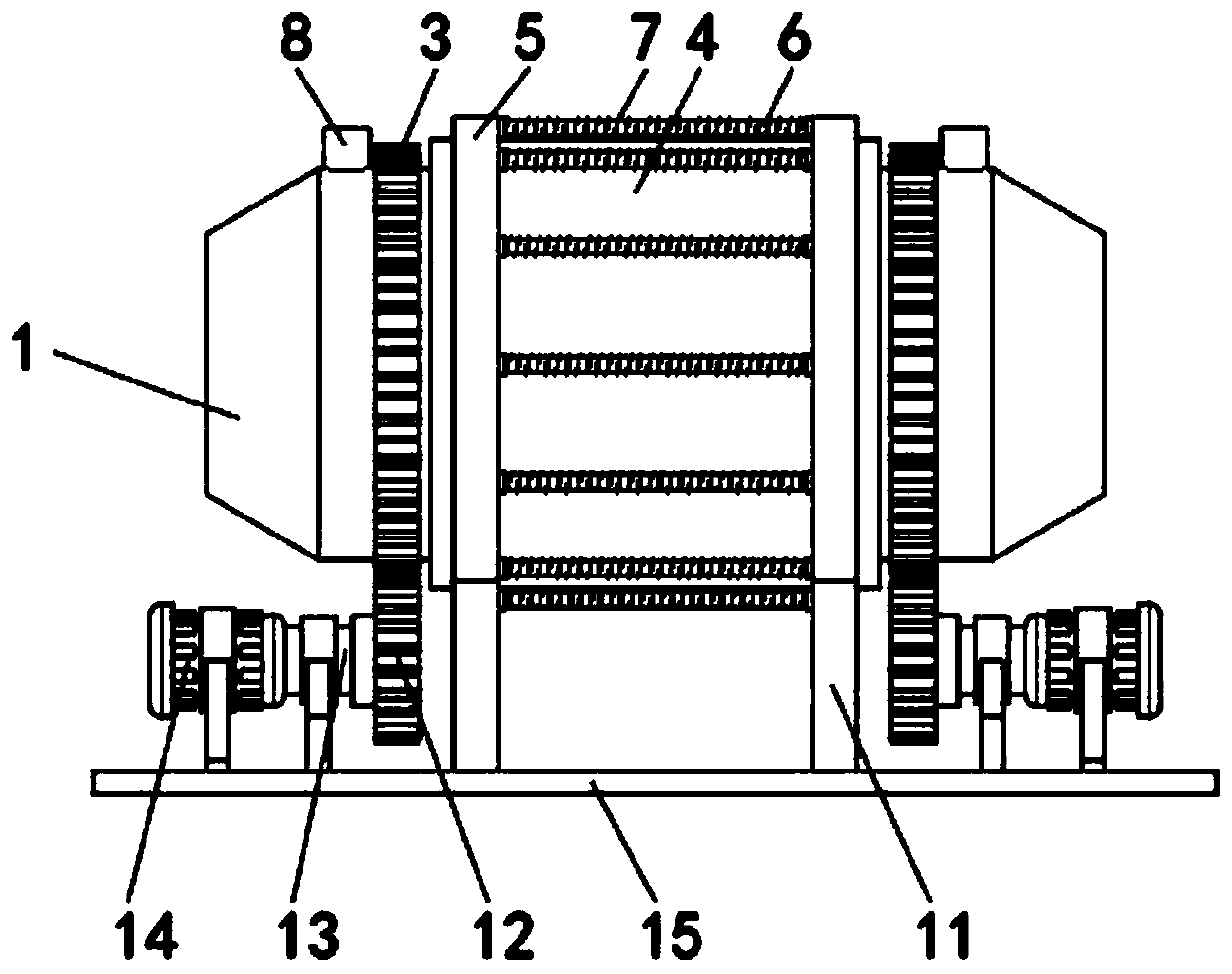

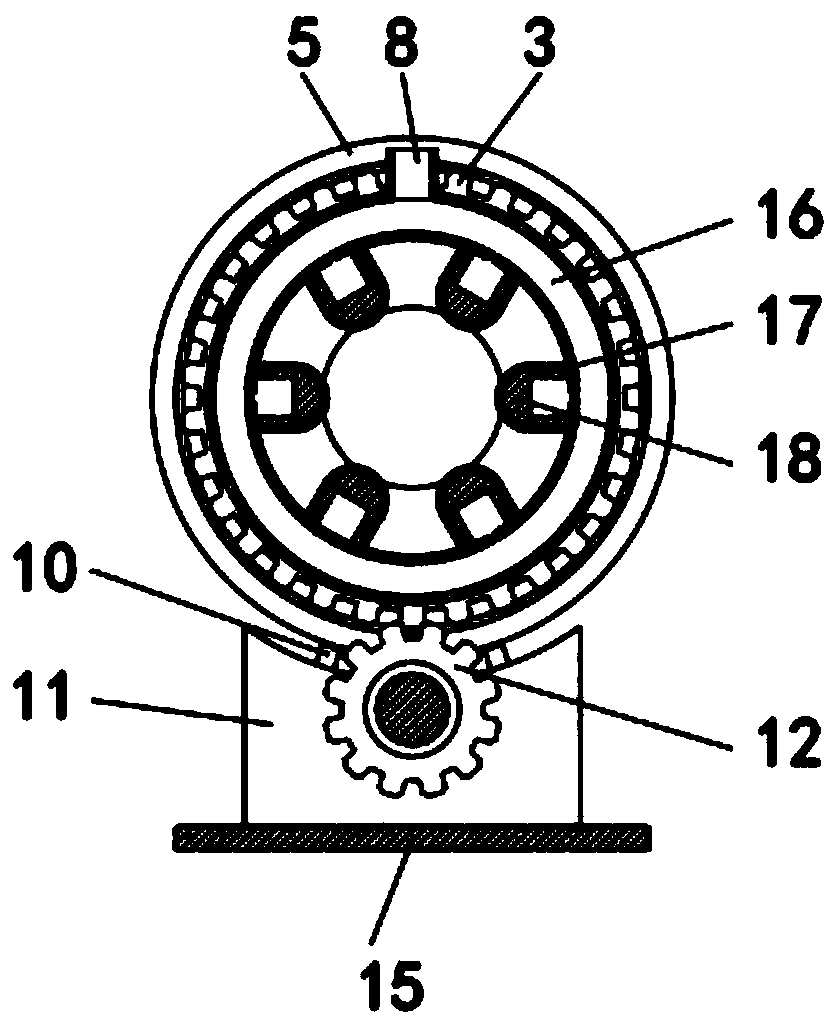

[0027] Embodiment one, with reference to Figure 1-5 , a shaftless polishing device for mat bamboo slices, comprising a bottom plate 15, a mixing drum 2 is arranged at the center of the top of the bottom plate 15, the two ends of the mixing drum 2 are respectively connected with a feed hopper 1 and a discharge hopper 9, and the outside of the mixing drum 2 Two gear sleeves 3 are symmetrically sleeved on both sides of the horizontal end, and the bottoms of the two gear sleeves 3 are meshed with a driving gear plate 12, and the outer sides of the two driving gear plates 12 are connected to the output shaft of the driving motor 14 Transmission connection, the outside of the transmission rod 13 is rotationally connected with the bottom plate 15 through the bearing sleeve, the drive motor 14 is fixedly connected with the bottom plate 15 by bolts, the inside of the mixing drum 2 is provided with a steam generating groove 16, and the inside of the mixing drum 2 is connected with a ven...

Embodiment 2

[0028] Embodiment two, refer to Figure 1-5 , the outer side of the mixing drum 2 is provided with a heating cylinder 4, and the two sides of the horizontal end of the outer wall of the heating cylinder 4 are symmetrically sleeved with conductive sleeves 5, and the inner sides of the two conductive sleeves 5 are welded with a heating rod 6, and the outer wall of the heating rod 6 A heating resistance wire 7 is wound and connected to it, and a plurality of heating rods 6 are arranged in total, and a plurality of heating rods 6 are arranged in sequence around the center of the circle of the conductive sleeve 5 at equal angles, and the two input ends of the heating resistance wire 7 are connected with two conductive wires respectively. The output end of the sleeve 5 is electrically connected, and support blocks 11 are symmetrically arranged on both sides of the bottom horizontal end of the heating cylinder 4, and the inside of the support block 11 is provided with a conductive blo...

Embodiment 3

[0029] Embodiment three, refer to Figure 1-4, the heating drum 4 is separated from the mixing drum 2, and the mixing drum 2 will rotate under the action of the driving motor 14, and the heating drum 4 is relatively fixed with the bottom plate 15. In the actual use process, through the rotation of the mixing drum 2, The heat generating area of the heating cylinder 4 is relatively changed, thereby increasing the heating area of the heating cylinder 4 and achieving the purpose of improving the heating efficiency of the heating cylinder 4 .

[0030] Working principle: firstly, inject the mat sheet into the inside of the mixing drum 2 through the feed hopper 1, when the mat sheet enters the inside of the mixing drum 2, start the driving motor 14 to drive the driving gear plate 12 to rotate, and the driving gear plate 12 will The mixing drum 2 is driven to rotate by the gear sleeve 3, and at the same time, the conductive sleeve 5 is powered by the conductive block 10, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com