Photocuring 3D printing system and method

A 3D printing and light curing technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problem of squeegee clearance, squeegee moving speed, affecting the accuracy of laying layer thickness, 3D model accuracy, affecting printing speed and other issues, to achieve reliable connection, reliable operation, and increase the printing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

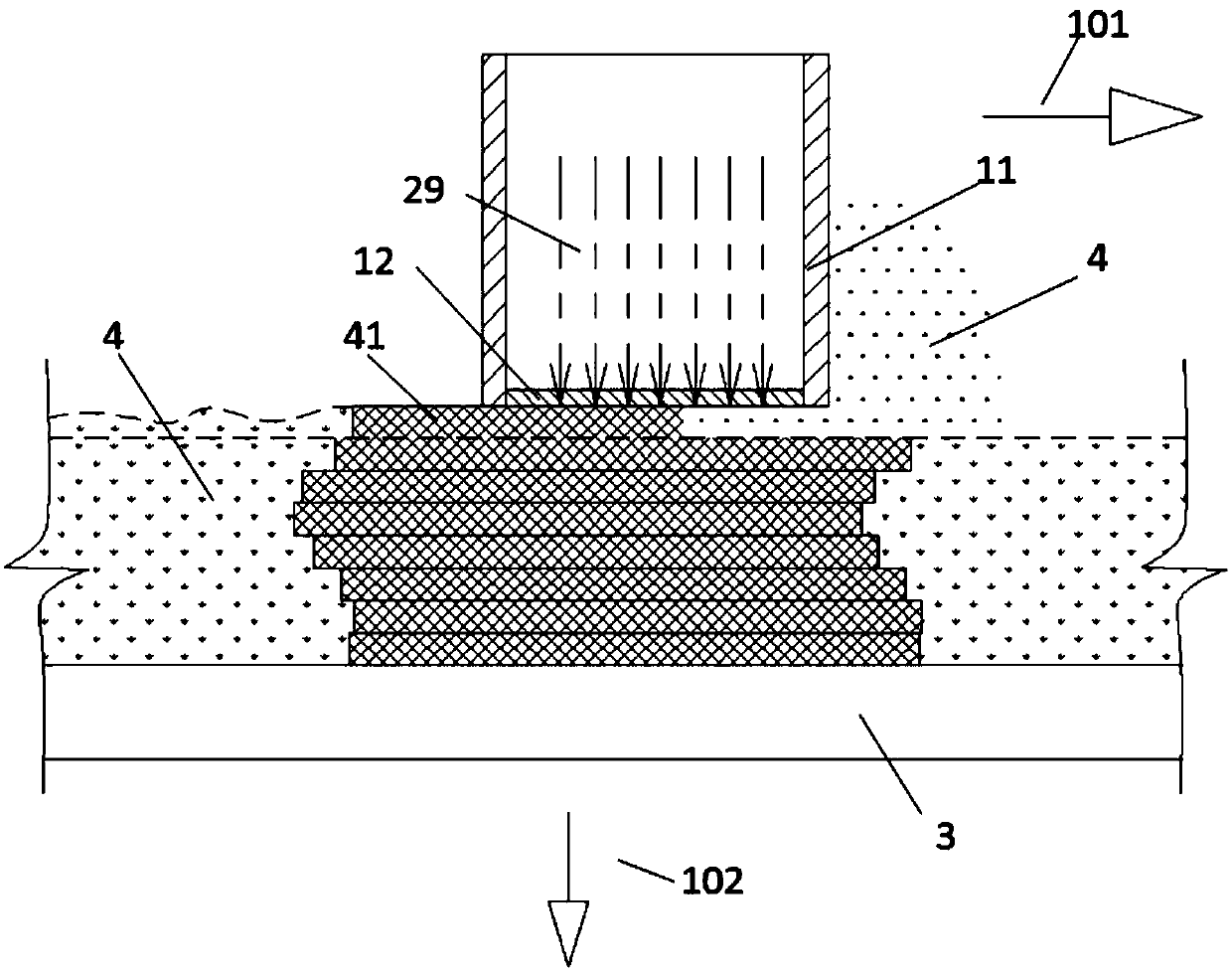

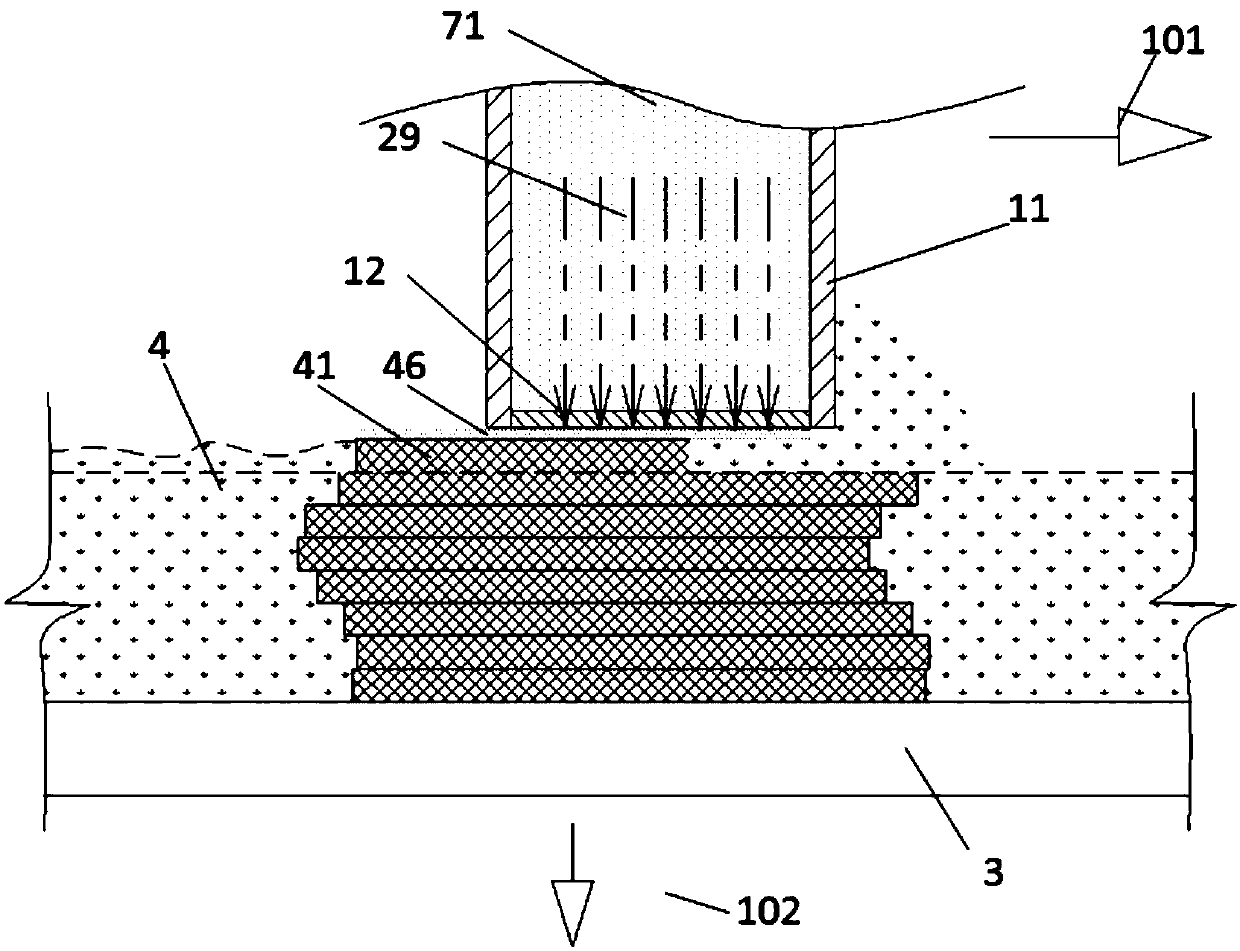

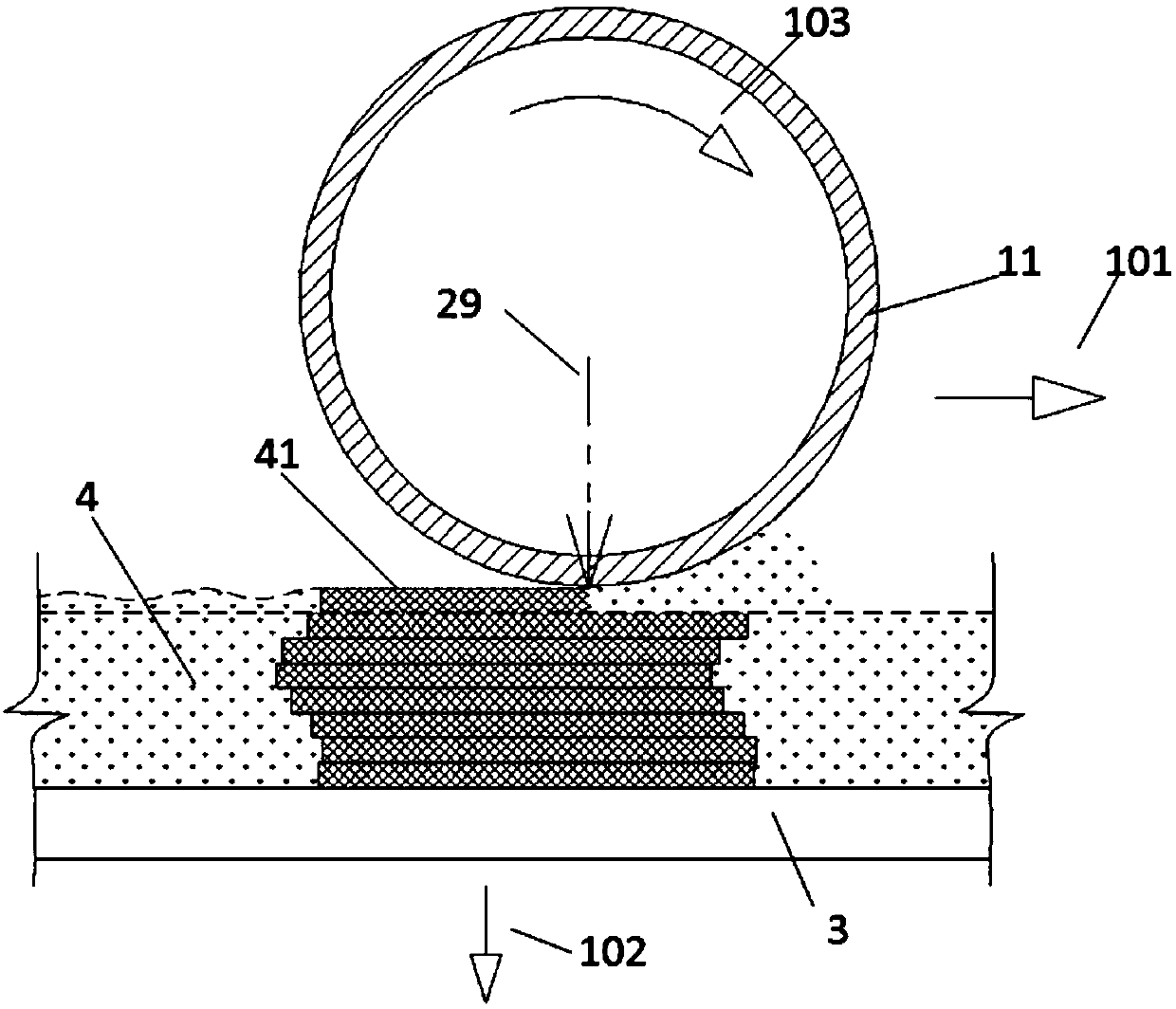

[0059] See attached Figure 1a At least a part of the bottom of the spreader 11 is a light-transmitting area 12, the light-transmitting area 12 can be realized by a light-transmitting plate, and the light beam 29 can pass through the light-transmitting area 12 to irradiate the photosensitive printing material 4 below the light-transmitting area 12 . During printing, the driver (not shown in FIG. 1 ) drives the spreader 11 and the material carrier 3 to move in relative translation, that is, the spreader 11 moves along the arrow 101, or the material carrier 3 can move in the direction opposite to the arrow 101. , laying the photosensitive printing material 4 on the material carrier 3 into a thin layer of material layer, when the laid photosensitive printing material 4 (ie the material layer) is still on the material layer 11 and the material carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com