Chitosan fiber facial mask cloth and preparation method thereof

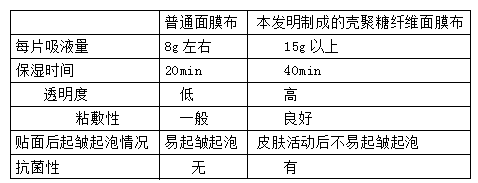

A technology of chitosan fiber and mask cloth, which is applied in the field of skin care products, can solve the problems of destroying the uniformity of the mask cloth surface, poor application effect, short moisturizing time, etc., and achieves easy control, long moisturizing time and slow reaction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The specific embodiment of the preparation method of a kind of chitosan fiber mask cloth of the present invention, comprises the steps:

[0025] (1) Only use chitosan fiber or mix chitosan fiber with other fibers to make chitosan fiber mask cloth, the content of chitosan fiber in chitosan fiber mask cloth is 5% to 100%;

[0026] (2) dissolving succinic anhydride in an organic solvent to form a bath, taking a certain amount of the chitosan fiber mask cloth and putting it into the bath, controlling the temperature and reaction time of the bath;

[0027] (3) After the reaction, the chitosan fiber mask cloth is centrifugally dehydrated;

[0028] (4) Soak the chitosan fiber mask cloth with an organic solvent to wash away the residual liquid of the reaction;

[0029] (5) Centrifuge and dehydrate the chitosan fiber mask cloth and then dry it to make a modified chitosan fiber mask cloth.

[0030] Preferably, the above-mentioned organic solvent is ethanol or methanol, and the ...

Embodiment 1

[0038] Only chitosan fiber and tencel fiber are mixed to make chitosan fiber mask cloth, the content of chitosan fiber in the chitosan fiber mask cloth is 15%, and the content of tencel fiber is 85%.

[0039] Preparation of reaction solution: 35 g of succinic anhydride was added to 5000 ml of 95% ethanol solution, and stirred until the succinic anhydride was completely dissolved to make a bath liquid.

[0040] Get above-mentioned chitosan fiber mask cloth 200g and put into prepared bath liquid, control the temperature of reaction solution to be 30 ℃, after reacting for 12h, take out chitosan fiber mask cloth, centrifugal dehydration.

[0041] The chitosan fiber facial mask cloth after the dehydration is placed in the 95% ethanol solution of 5000ml alcohol washing 2 times again, centrifugal dehydration is dried, finally, the chitosan fiber facial mask cloth of making modification.

[0042] Get a piece of dried chitosan facial mask cloth to test the water absorption, and the tes...

Embodiment 2

[0044] Only chitosan fiber and tencel fiber are mixed to make chitosan fiber mask cloth, the content of chitosan fiber in chitosan fiber mask cloth is 30%, and the content of tencel fiber is 70%.

[0045] Preparation of reaction solution: add 450 g of succinic anhydride to 25 L of 90% ethanol solution, and stir until succinic anhydride

[0046] All anhydrides are dissolved to make a bath.

[0047] Get above-mentioned chitosan fiber facial mask cloth 1000g and put into prepared bath liquid, control the temperature of bath liquid to be 30 ℃, after reacting for 12h, take out chitosan fiber facial mask cloth, centrifugal dehydration.

[0048] The chitosan fiber mask cloth after the dehydration is placed in the 95% ethanol solution of 25L after alcohol washing 2 times again, centrifugal dehydration is dried. Get a piece of dried facial mask cloth to test the water absorption, and the test water absorption is 22g / g (that is, the maximum water absorption of the chitosan fiber mask c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com