A high-temperature valve-regulated sealed lead-acid battery

A lead-acid battery and high-temperature valve technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery, etc., can solve the problems of not meeting the use requirements, not being scientific and reasonable, and shortening the life, so as to avoid premature aging of battery capacity, Good electrochemical performance, reducing the effect of self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

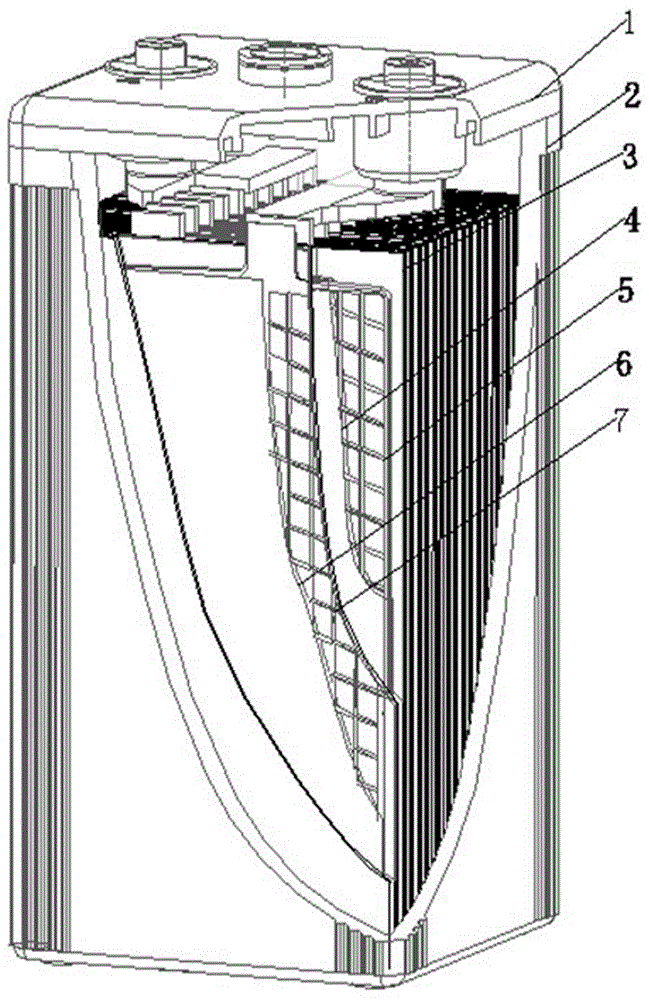

Image

Examples

Embodiment 1

[0019] Example 1: Take a 2V500Ah battery with common specifications as an example:

[0020] 1. Plate production:

[0021] Use high tin and low calcium lead alloy (the content of tin is 2.0%, the content of calcium is 0.08%, the balance is lead) to cast the positive grid 7;

[0022] In addition to the lead powder, the positive active material also contains 0.8% polyester fiber, 8.0% sulfuric acid (1.4g / ml), 13% deionized water, 0.5% graphite, and 0.08% Bi relative to the mass of the lead powder. 2 O 3 , 0.1% Sb 2 O 3 , 0.08% SnSO 4 , 0.6% polyaniline, 0.6% 4Pb·PbSO 4 . Lead powder, polyester fiber, graphite, Bi 2 O 3 , Sb 2 O 3 , SnSO 4 , Polyaniline, 4Pb·PbSO 4 Dry mixing first, then add deionized water of formula for wet mixing. After wet mixing is evenly mixed, slowly add formula of sulfuric acid solution, stir it to form positive lead paste 6, fill it on positive grid 7, and solidify After drying, a positive electrode plate is formed;

Embodiment 2

[0028] Example 2: Prepare a 2V500Ah battery according to the method of Example 1. The difference is:

[0029] The tin content of the positive grid is 1.2%, and the calcium content is 0.04%;

[0030] In addition to the lead powder, the positive active material also contains 1.0% polyester fiber, 10% sulfuric acid (1.4g / ml), 11% deionized water, 0.2% graphite, and 0.04% Bi relative to the mass of the lead powder. 2 O 3 , 0.05% Sb 2 O 3 , 0.04% SnSO 4 , 0.2% polyaniline, 0.2% 4Pb·PbSO 4 ;

[0031] In addition to the lead powder, the negative active material also contains 1.0% polyester fiber, 11% sulfuric acid (1.4g / ml), 11% deionized water, 0.4% lignin, and 0.4% relative to the mass of lead powder. Humic acid, 0.2% acetylene black, 0.1% indulin, 0.1% anisaldehyde;

[0032] SiO 2 The weight percentage relative to the electrolyte is 0.5%.

[0033] The battery prepared in the above embodiment was subjected to a high-temperature accelerated floating charge life test. The test procedure is: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com