Energy-saving steam turbine generator set utilizing low-pressure saturated steam to generate electricity

A technology of generator sets and generators, applied in the directions of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased expansion ratio, high exhaust pressure, inability to achieve negative pressure, etc., and achieve reduced radial size, The effect of large power generation and small starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

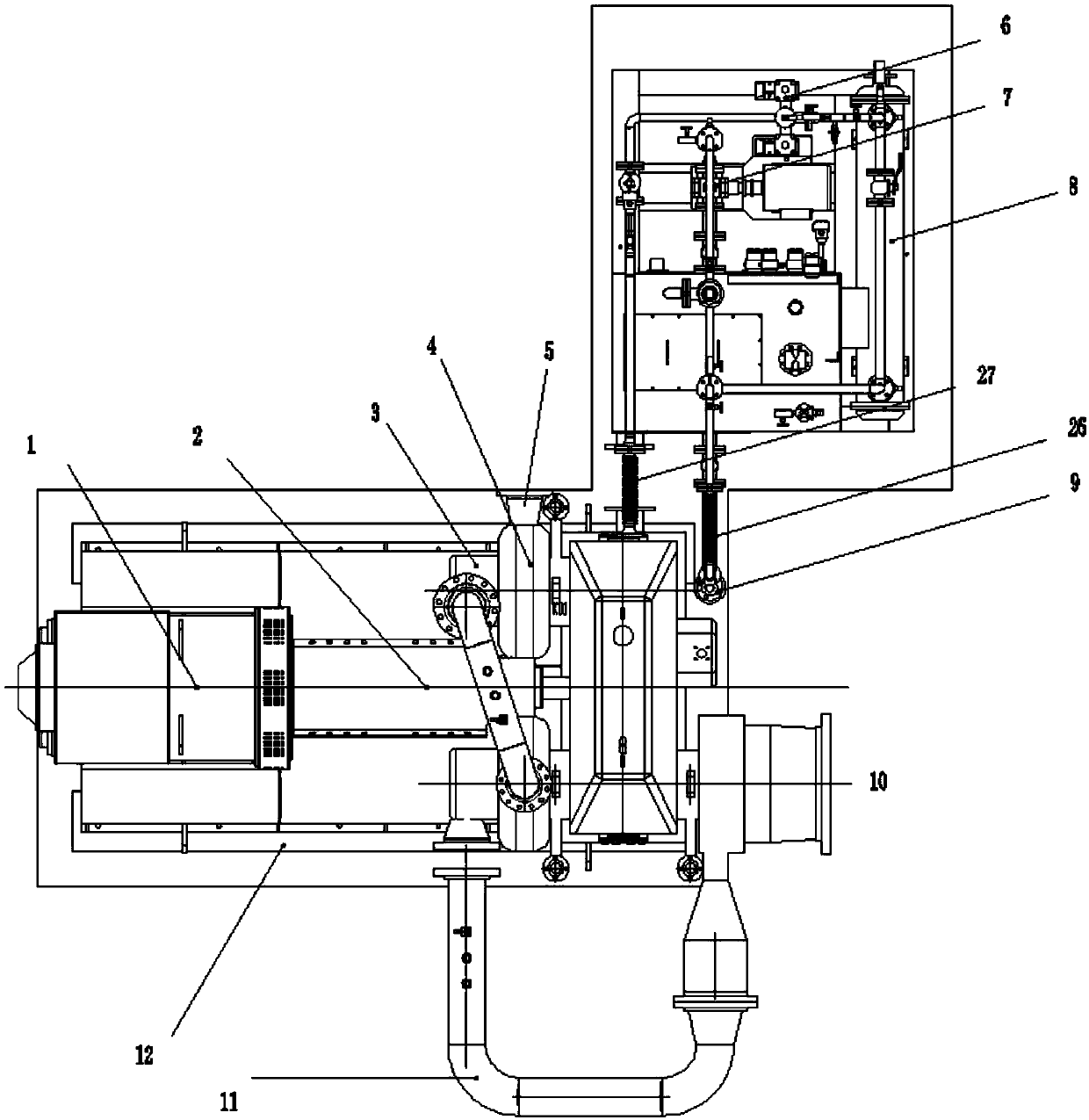

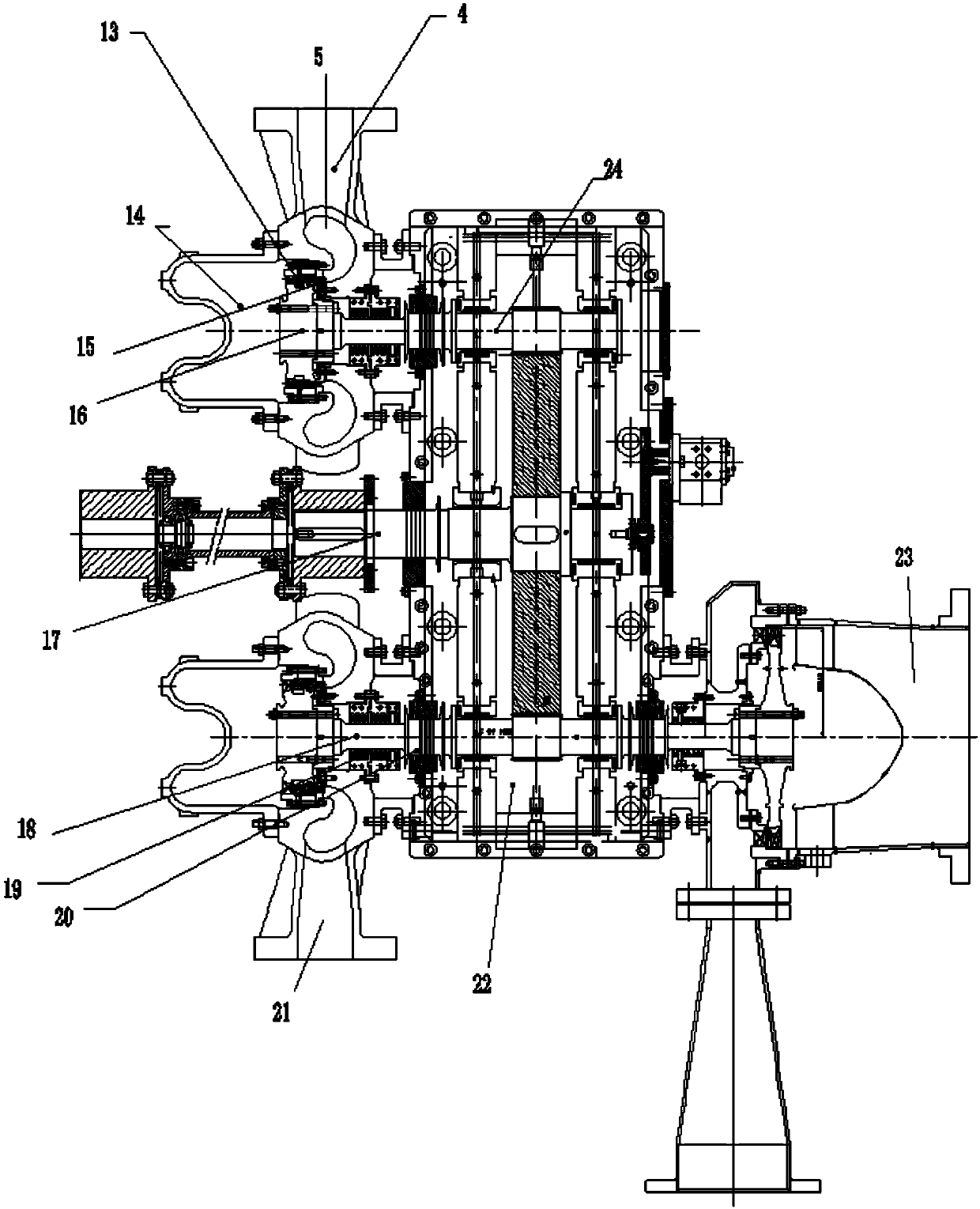

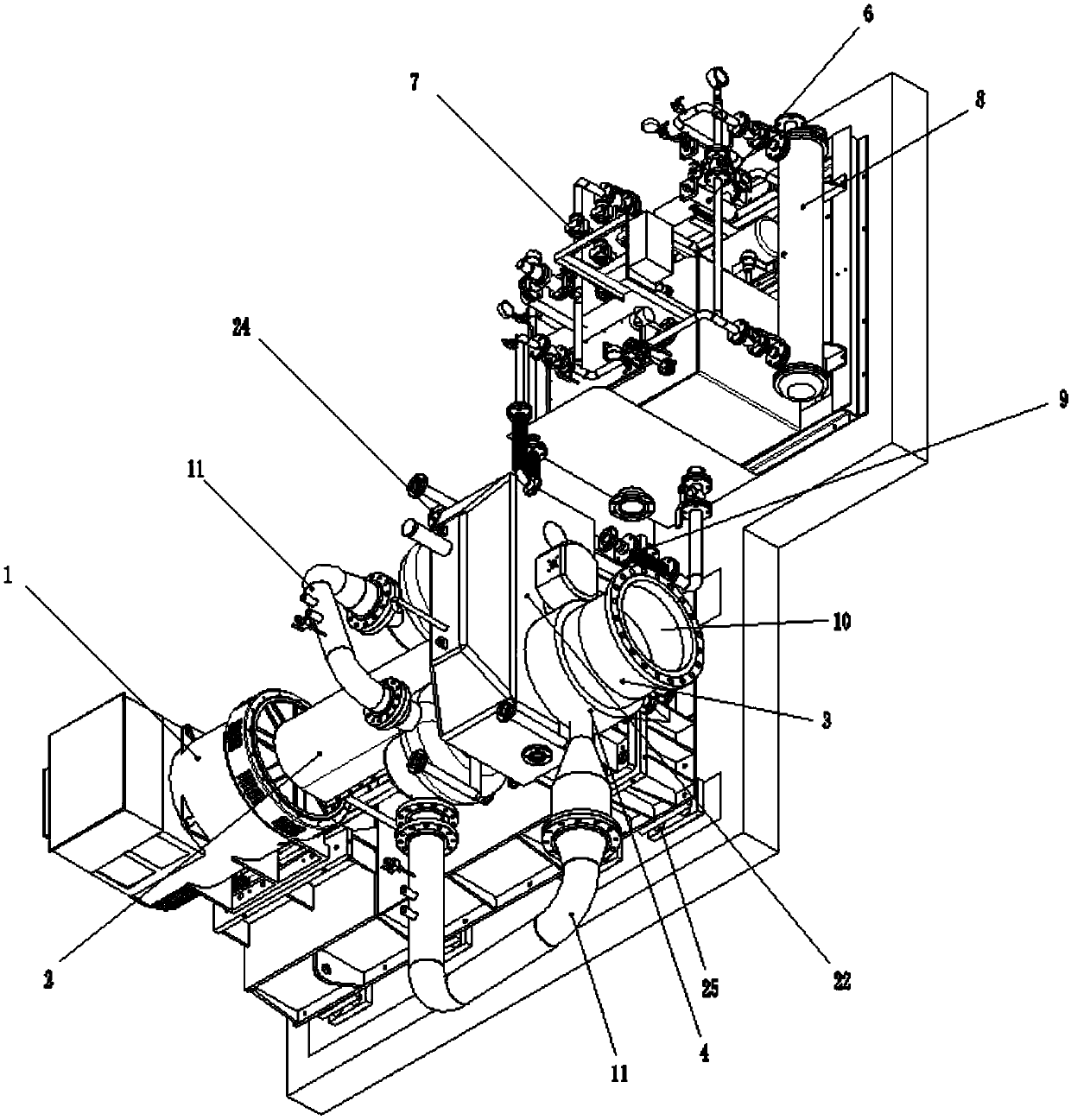

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0017] see Figure 1-3 , an energy-saving steam turbine generator set utilizing low-pressure saturated steam to generate electricity, including a skid-mounted base 12; a generator 1 is installed on the skid-mounted base 12 through an anti-vibration support base 25, which can not only pass through the installation space for other components, but also It can effectively absorb the dynamic load of the unit, so that the foundation plane only bears the static load, without grouting, anchor bolts and other complicated civil foundations; the right side of the generator 1 is connected to the reduction gearbox 22 through the coupling 2 It is connected with the low-speed shaft 17; the reduction gearbox 22 is connected and installed in the middle of the skid-mounted base 12, and the front and rear sides are connected with the first high-speed shaft 18 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com