Heating element, heater heating device, temperature control heater and intelligent heating system

A heating element and heater technology, which is applied in the fields of temperature control heaters and intelligent heating systems, heating elements, and heater heating devices, can solve the problems of low electrothermal conversion efficiency, inability to adjust temperature, and poor energy gathering effect, and achieve electric heating High conversion efficiency, sensitive use, convenient temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

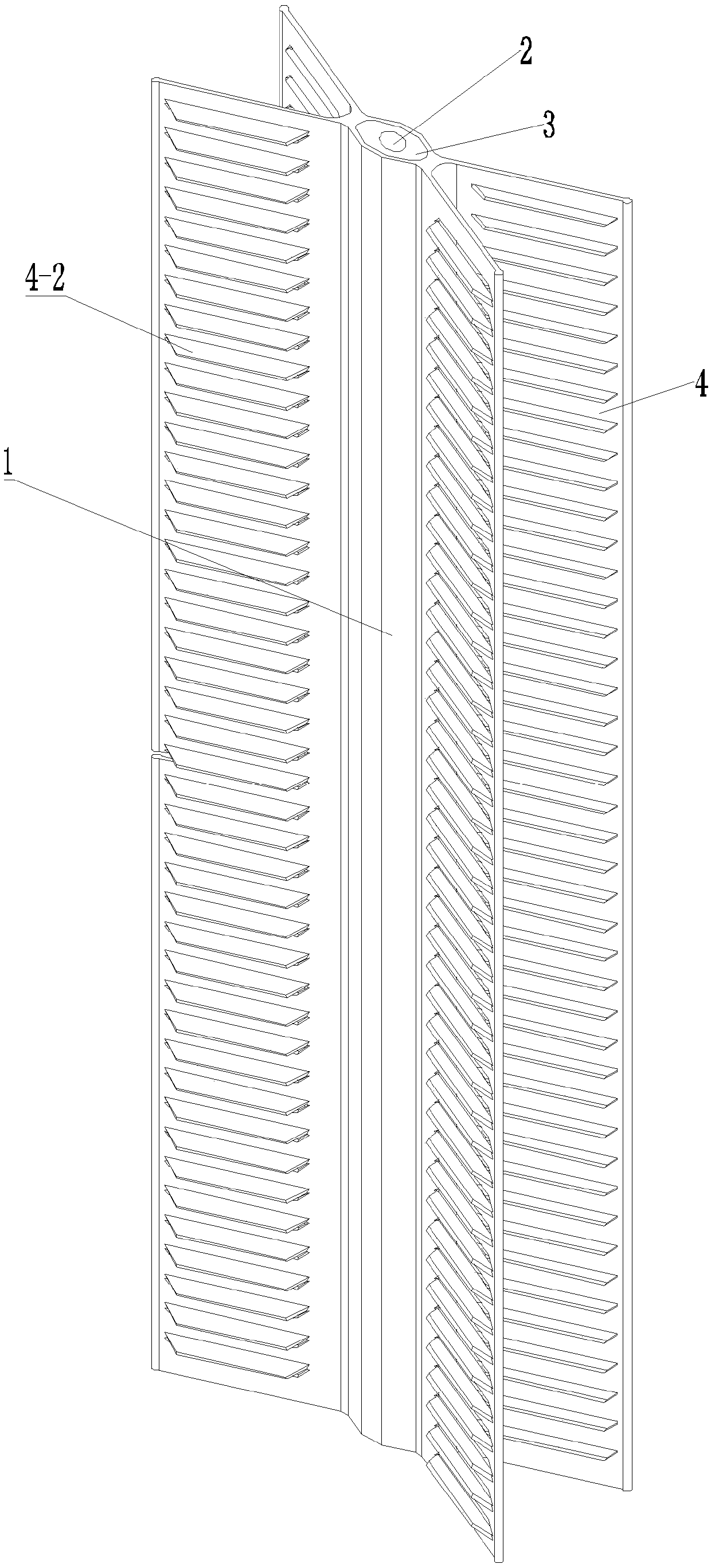

[0262] Attached below in conjunction with the instructions Figure 1-12 The technical scheme of the present invention will be described in detail.

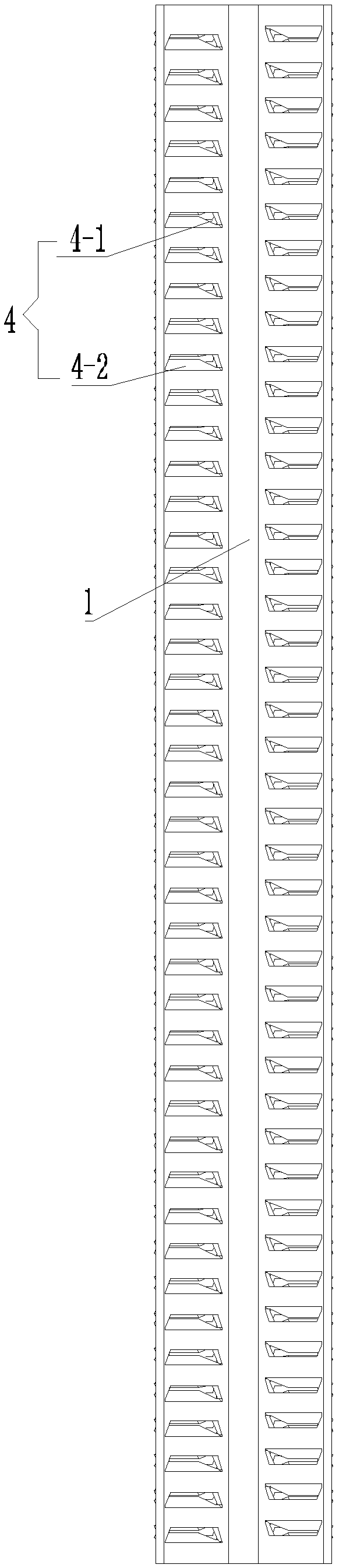

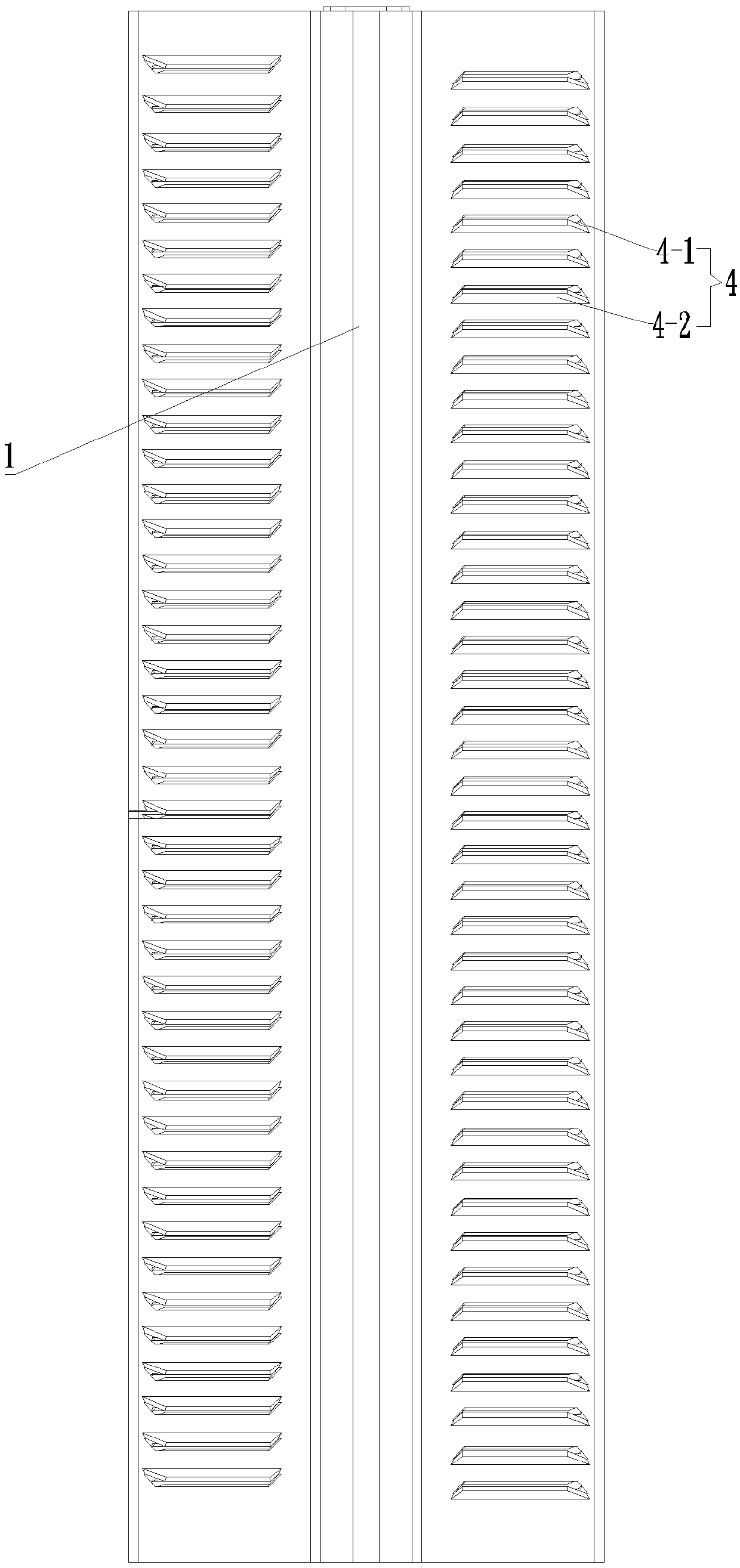

[0263] A heating element includes at least one set of heating element units, each set of heating element units includes a hollow central sleeve 1, a heating wire 2, which is filled in the cavity of the central sleeve 1, and the heating wire 2 and the central sleeve 1 Good thermal conductivity and insulation between the inner walls 3 and at least one heat sink 4 connected to the outer wall of the central sleeve 1; the total heat dissipation area of the heat sink 4 = [(0.8 ~ 1.6) × required heating power Wattage] cm 2 .

[0264] The radiating fins 4 extend along the central axis of the central sleeve 1; each radiating fin 4 is provided with radiating grooves 4-1 arranged at intervals from top to bottom and extending in a direction perpendicular to the central axis of the central sleeve 1, each The upper edge of the heat dissipation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com