Lithium bromide II adsorption and compression composite type high-temperature heat pump system and working method

A lithium bromide absorption, high-temperature heat pump technology, applied in heat pumps, sorption machines, refrigeration and liquefaction, etc., can solve problems such as high temperature requirements for driving waste heat sources, and low temperature waste heat cannot be effectively recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] Furthermore, the alphabetic terms mentioned in the present invention, such as a, b, c, d, e, f, g, etc., are only for reference to the exit and entrance of the accompanying drawings. Therefore, the use of alphabetical terms is used to illustrate and understand the present invention, but not to limit the present invention.

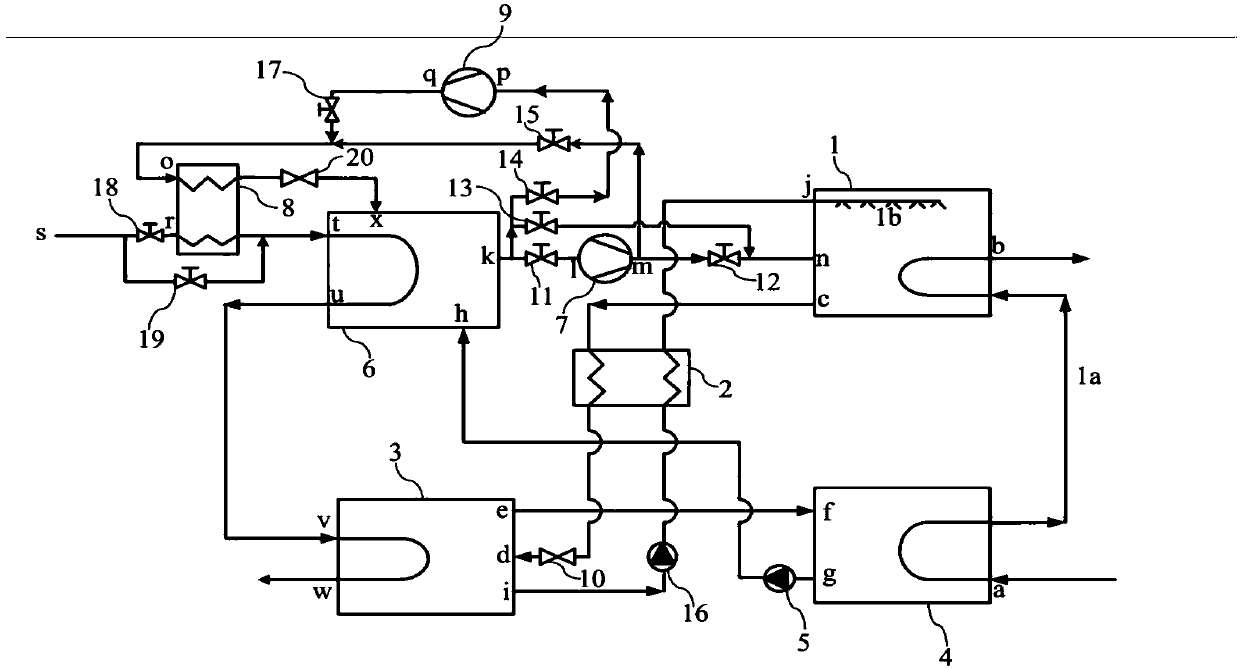

[0040] Such as figure 1As shown, a second-type lithium bromide absorption and compression compound high-temperature heat pump system of the present invention includes a first shut-off valve 19, an evaporator 6, a second shut-off valve 11, a first water vapor compressor 7, and a third shut-off valve 12 , water vapor absorber 1, solution regenerator 2, first throttling valve 10, water vapor generator 3, condenser 4, water pump 5 and solution pump 16, heat exchange pipe 1a is from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com