Testing device and method of bending resistance of fiber materials by adopting double-end clamping three-bending method

A fiber material and testing device technology, applied in the direction of applying a stable bending force to test the strength of materials, measuring devices, and analyzing materials, can solve problems such as difficult bending force, fiber skew, slippage, etc., to improve reliability and Reproducibility, accurate and reliable instrument performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

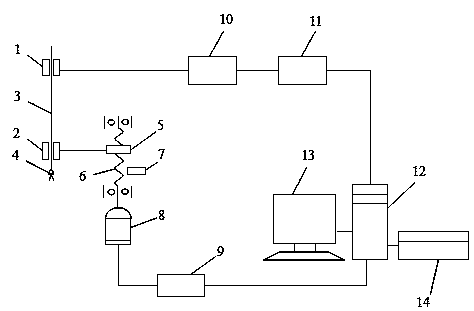

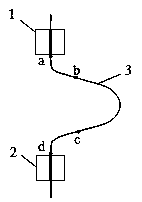

[0027] see figure 1 , 2 , which is a structural schematic diagram of a preferred embodiment of a fiber material bending resistance test device with double-end clamping and three-bending method of the present invention. As shown in the figure: it includes an upper holder 1 and a lower holder 2 with jaws for clamping the upper and lower ends of the sample 3 respectively; The counterweight that bears the initial tension and straightens under the action; the lower clamper 2 is driven by the driving mechanism to move up and down, and the lower clamper 2 is clamped between the upper clamper 1 and the lower clamper 3 during the upward movement The middle sample 3 can form a three-bend configuration; the upper holder 1 is connected with a load cell 10 .

[0028] In this embodiment, the counterweight is a tension clip 4 . When in use, the upper holder 1 clamps the upper end of the fiber material sample 3, and the tension clamp 4 clamps the other end of the fiber material sample 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com