A method for detecting galvanic atmospheric corrosion sensor

A technology for atmospheric corrosion and corrosion detection, applied in the field of sensor detection, can solve the problems of difficulty in meeting the requirements of mass production process of sensors and long evaluation period, and achieve the effect of satisfying comparability requirements, ensuring results, and ensuring accurate and credible results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

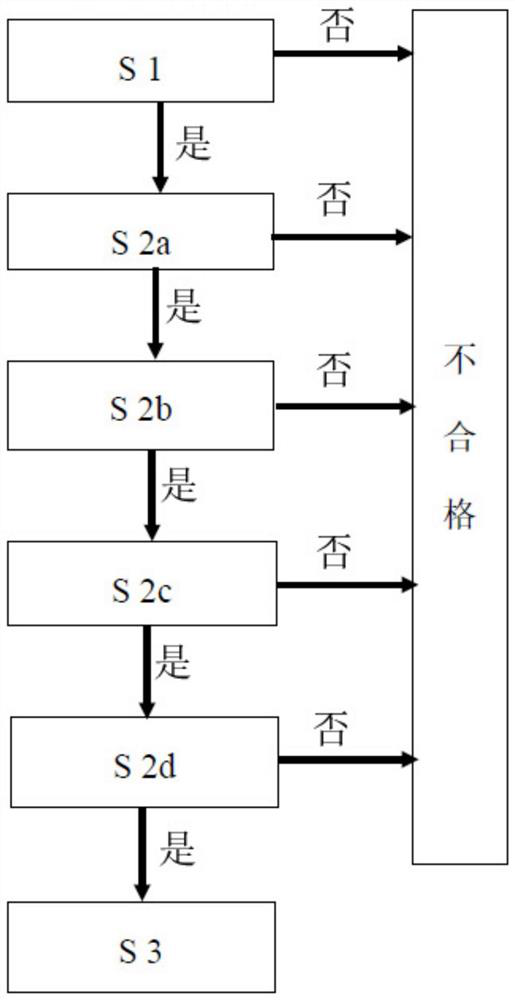

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the anode of the galvanic atmospheric corrosion sensor is made of metal zinc, and the cathode is made of metal platinum. The structure of the galvanic couple type atmospheric corrosion sensor is a spaced form in which cathodes and anodes are alternately arranged, and the cathodes and anodes are respectively provided with lead wires. The electrode area is 10cm 2 .

[0061] First, at 25° C. and 30% RH, a multimeter was used to detect the insulation resistance between the anode and the cathode of the above-mentioned galvanic atmospheric corrosion sensor. The positive pole of the multimeter is connected to the anode of the galvanic atmospheric corrosion sensor, and the other pole of the multimeter is connected to the cathode of the galvanic atmospheric corrosion sensor. The detected resistance value is 80MΩ, which preliminarily judges that the galvanic atmospheric corrosion sensor is effective.

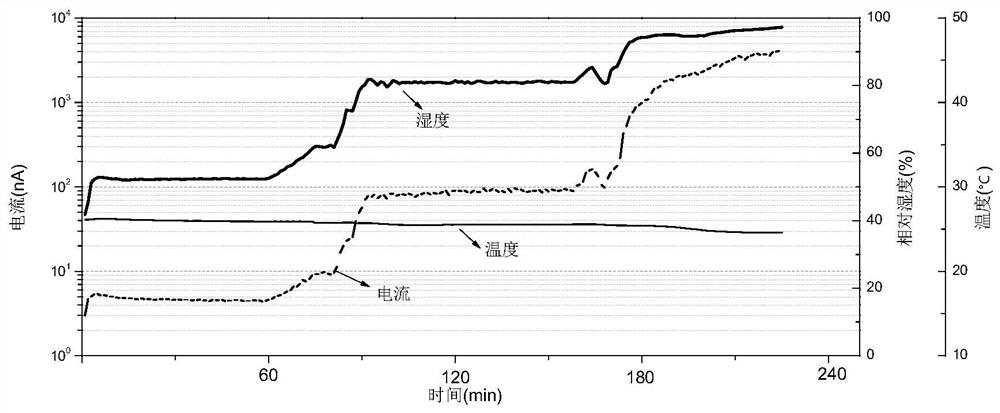

[0062] Next, in the temperature and humidity alternating...

Embodiment 2

[0070] In this embodiment, the anode of the galvanic atmospheric corrosion sensor is made of metal aluminum, and the cathode is made of metal gold. The structure of the galvanic couple type atmospheric corrosion sensor is a spaced form in which cathodes and anodes are alternately arranged, and the cathodes and anodes are respectively provided with lead wires. The electrode area is 10cm 2 .

[0071] First, at 25°C and 30% RH, use a multimeter to detect the insulation resistance between the anode and cathode of the galvanic atmospheric corrosion sensor. The positive pole of the multimeter is connected to the anode of the galvanic atmospheric corrosion sensor, and the other pole of the multimeter is connected to the cathode of the galvanic atmospheric corrosion sensor. The detected resistance value is 20MΩ, which preliminarily judges that the galvanic atmospheric corrosion sensor is effective.

[0072] Next, in the temperature and humidity alternating box described above, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com