Embedded facility light environment optimization regulation system combining illumination frequency and duty ratio

A technology of regulation system and duty cycle, applied in the direction of light control, control/regulation system, non-electric variable control, etc., can solve problems such as neglect, difficulty in improving light supplement efficiency, and output signal distortion, etc., to achieve Improve the efficiency of light supplement, improve the efficiency of photosynthesis, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

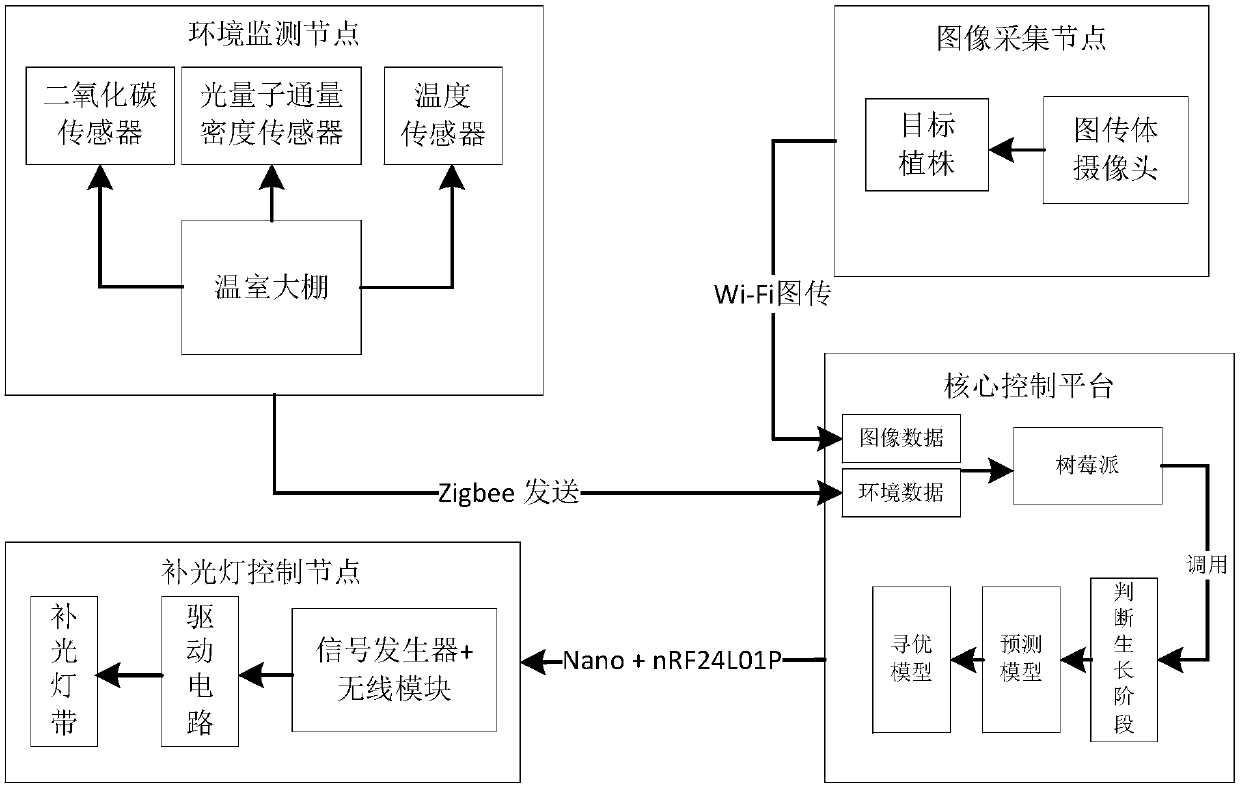

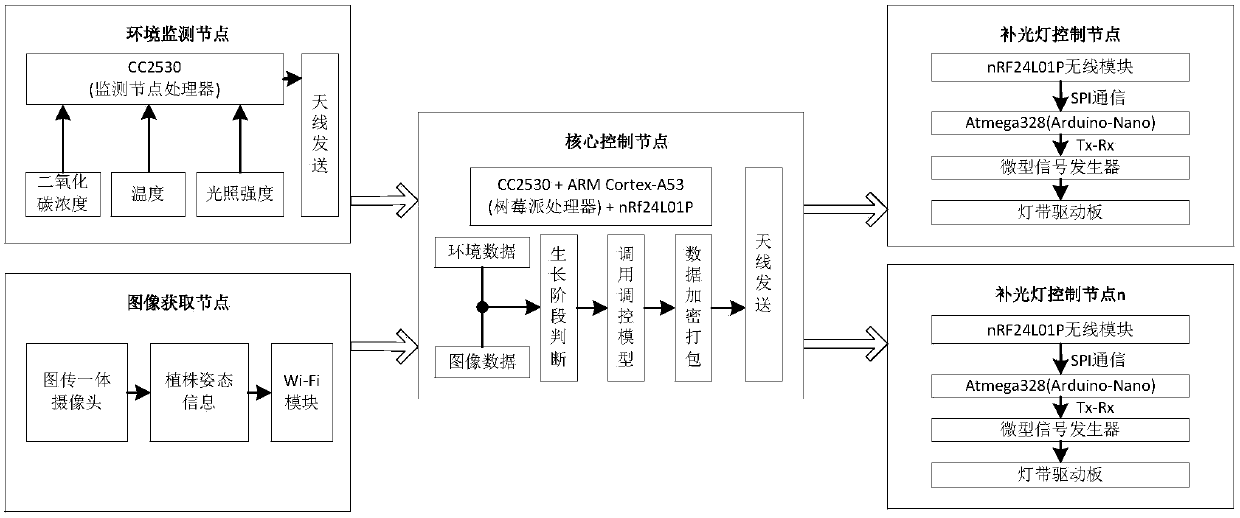

[0034] Such as figure 1 and figure 2 As shown, the hardware part of the present invention is divided into four main nodes according to functions, which are respectively:

[0035] Environmental monitoring nodes based on high-precision sensors and ZigBee, including ZigBee terminal modules for wireless data transmission and carbon dioxide sensors (non-dispersive infrared carbon dioxide sensors), optical quantum flux density sensors (solar radiation sensors) and temperature sensors for environmental monitoring (digital temperature sensor). The communication between it and the core control platform uses the CC2530 chip as the core processor, and uses the ZigBee technology with the characteristics of ad hoc network and low power consumption as the main communication method. Each sensor forms a sensor network and is distributed around the detected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com