Sludge particles for removing heavy metal and preparation method and application thereof

A technology of sludge granules and spherical granules, applied in the fields of alkali metal compounds, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of long-term removal of heavy metals, sludge resource utilization, water treatment facility penetration rate Reduce and reduce the service life of facilities and other issues, to achieve the effect of effective control of heavy metals, low loss rate, and not easy to be washed away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

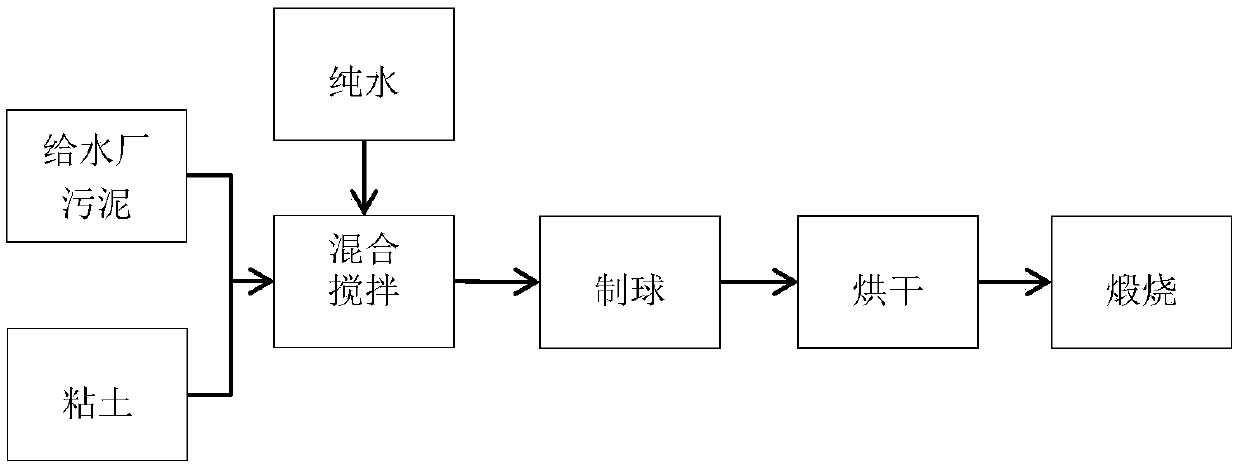

[0031] The preparation process of the following sludge particle adsorbent is as follows: figure 1 shown.

[0032] The oven DHG-9070A used below was purchased from Shanghai Jinghong Experimental Equipment Co., Ltd.

[0033] The muffle furnace SX used below 2 -4-10, Tianjin Zhonghuan Experimental Electric Furnace Co., Ltd.

Embodiment 1

[0035] Weigh 120g of water supply plant sludge powder and 240g of clay, add appropriate amount of water to mix, mechanically stir evenly, make spherical particles with a particle size of about 2mm, and dry at 105°C for 2 hours to make the water content less than 2%. Put it in a muffle furnace for calcination at 600°C for 60 minutes, and after cooling, get the sludge particle adsorbent for water supply plant.

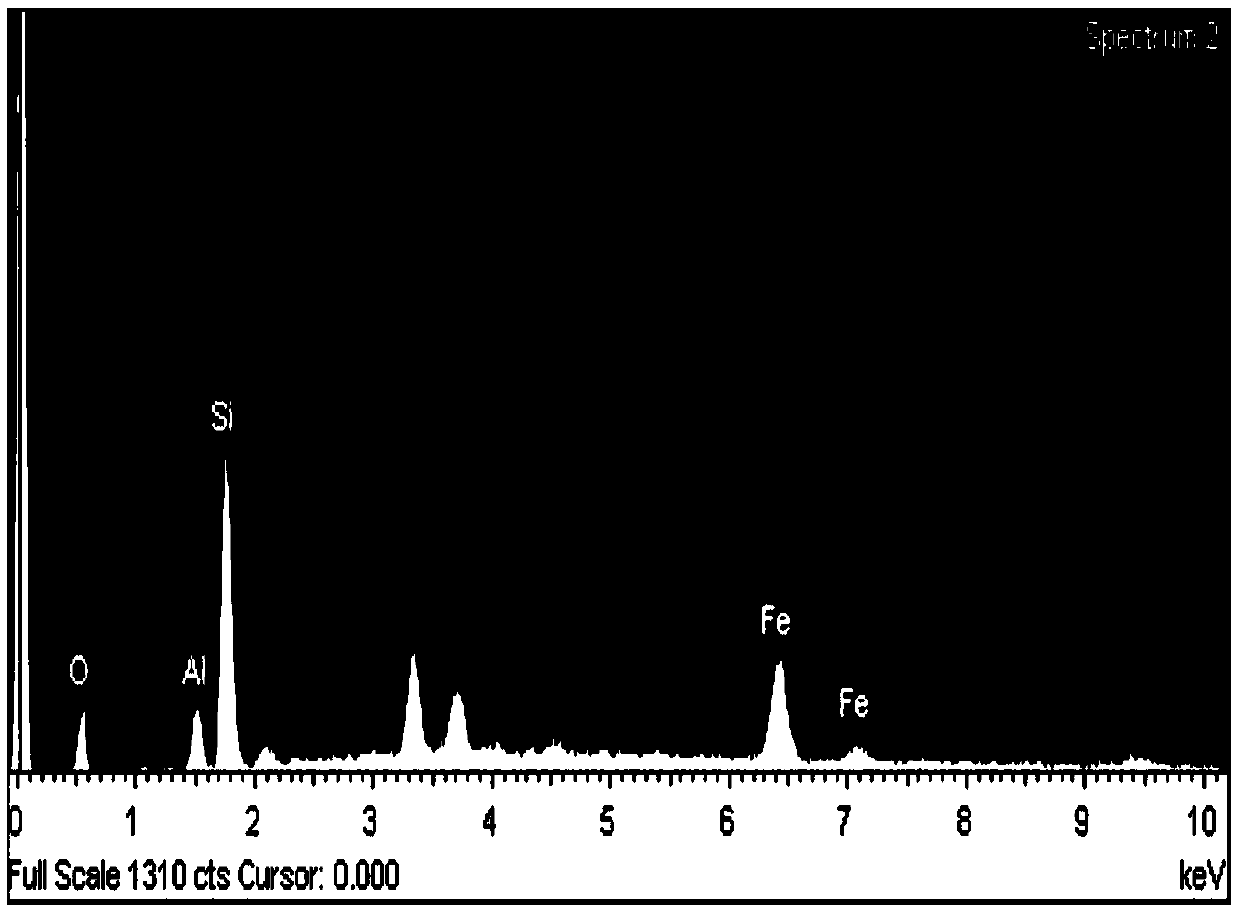

[0036] Using a scanning electron microscope to observe the internal morphology of the water plant sludge particle adsorbent prepared in this example, the results are as follows figure 2 shown. It can be seen that the surface of the sludge particle adsorbent in the water supply plant is rough and the pores are developed; the energy spectrum ( image 3 ) shows that the sludge particle adsorbent of the water supply plant is mainly composed of O, Si, Al, and Fe, indicating that the particle has a strong adsorption capacity.

[0037] The water plant sludge particle adsorbe...

Embodiment 2

[0039] The water supply plant sludge particle adsorbent differs from Example 1 only in that the dry weight ratio of water supply plant sludge powder to clay is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com