Vehicle-mounted in-situ remediation equipment for heavy metal pollution of farmland soil

An in-situ repair and heavy metal technology, applied in the field of mechanical equipment, can solve the problems of difficulty in the research and development or integrated application of separation devices, restrict the large-scale promotion of new materials for chelating magnetic removal, and achieve efficient removal and recovery at low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical equipment of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. The following examples are only used to illustrate and explain the present invention, but not to limit the technical equipment of the present invention.

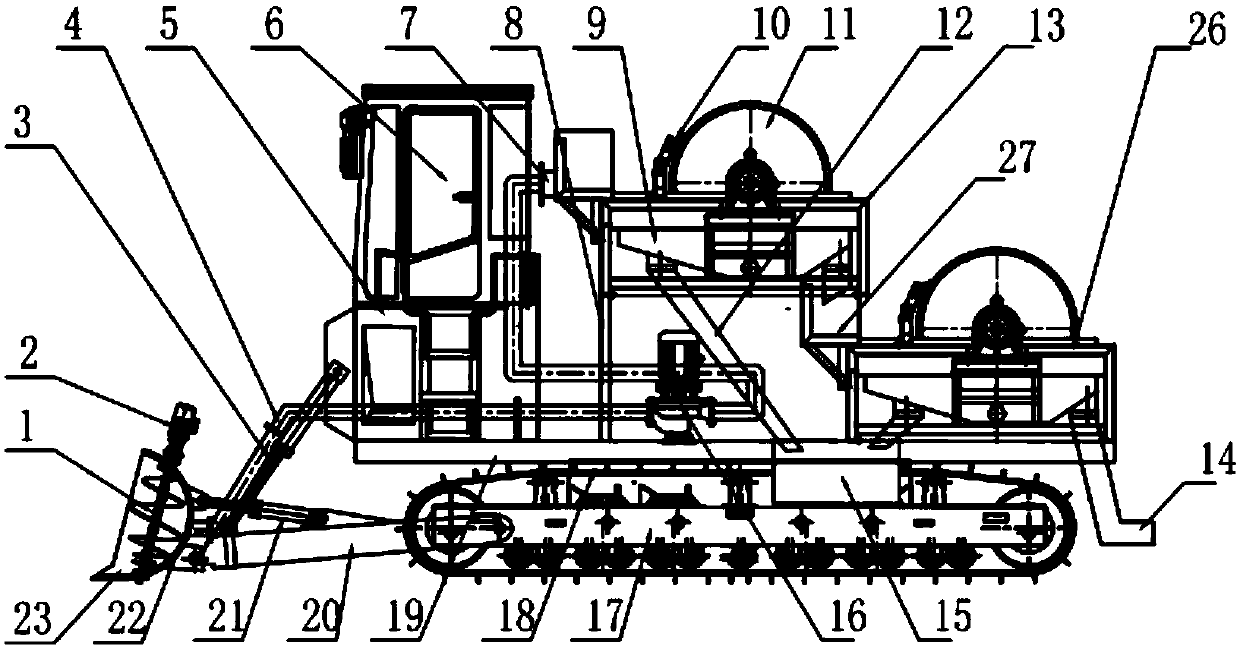

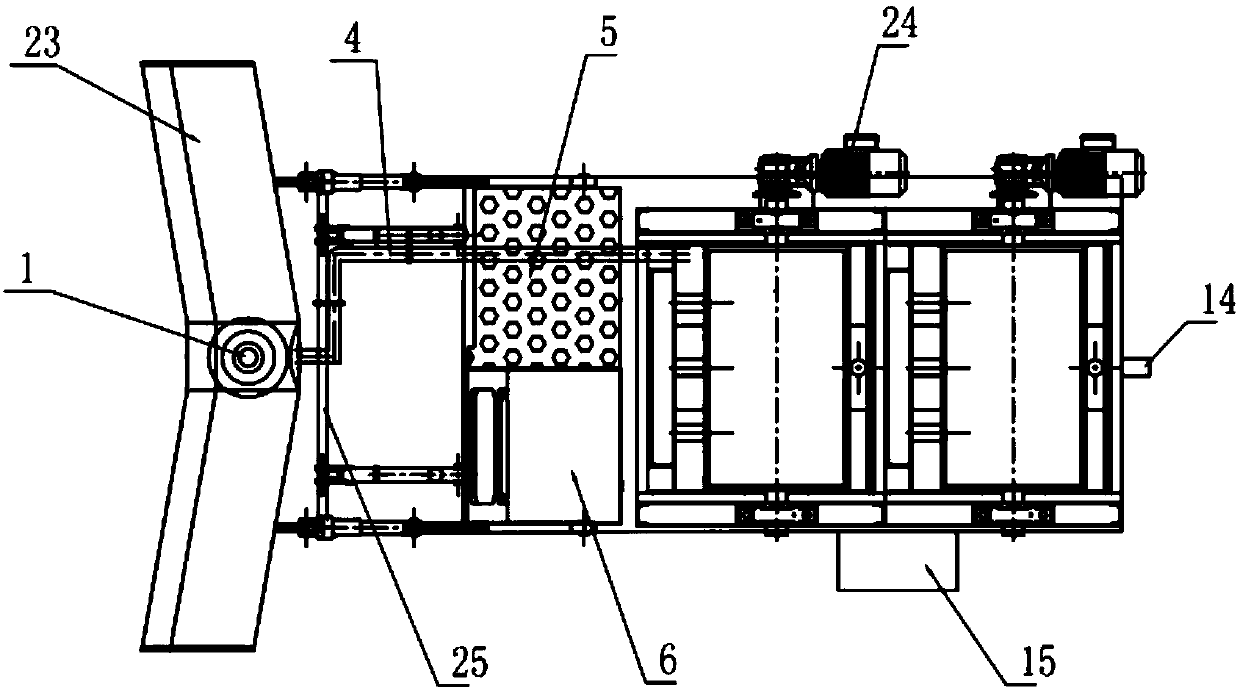

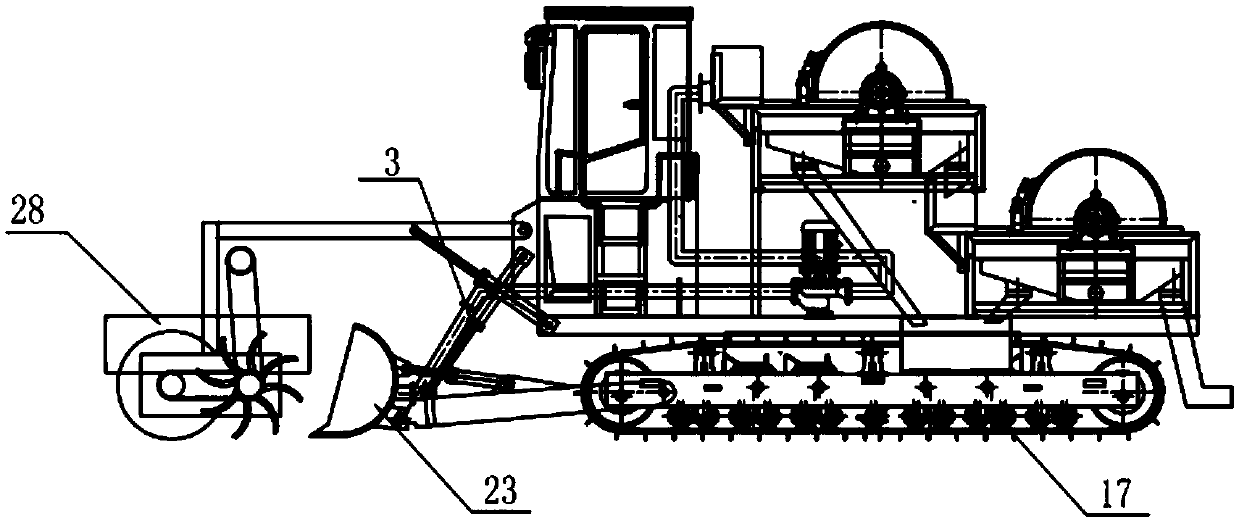

[0031] as attached Figure 1-4 As shown, a vehicle-mounted in-situ remediation equipment for heavy metal pollution in farmland soil: its structure includes: a vehicle-mounted system, a push bucket retrieving system and a magnetic recovery system;

[0032] In the vehicle-mounted system, a rotating platform 18 is arranged on the upper part of the mobile device 17, and the rotating platform 18 is located under the floor frame 19, so that the vehicle body can change direction freely horizontally. The whole vehicle is driven by the engine room 5 and manipulated through the cab 6 .

[0033] In the push bucket retrieving system, the rear end of the support rod 20 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com