Aluminum bronze continuous casting furnace based on electromagnetic stirring and autonomous stirring

The technology of electromagnetic stirring and electromagnetic stirrer is applied in the field of aluminum bronze continuous casting furnace, which can solve the problems of inability to collect and process impurities, and inability to fully consume or decompose impurities and copper slag, so as to achieve the effect of ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

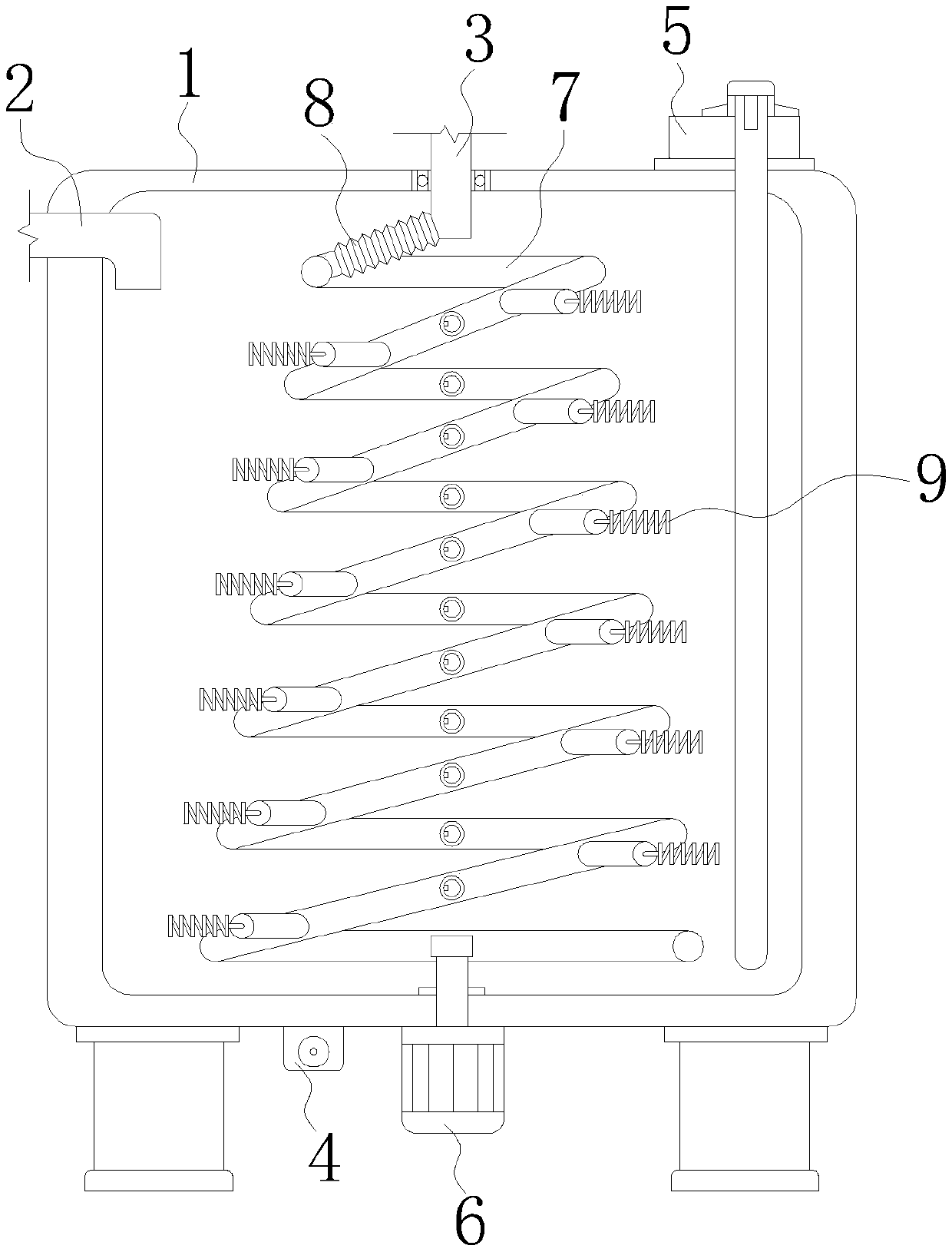

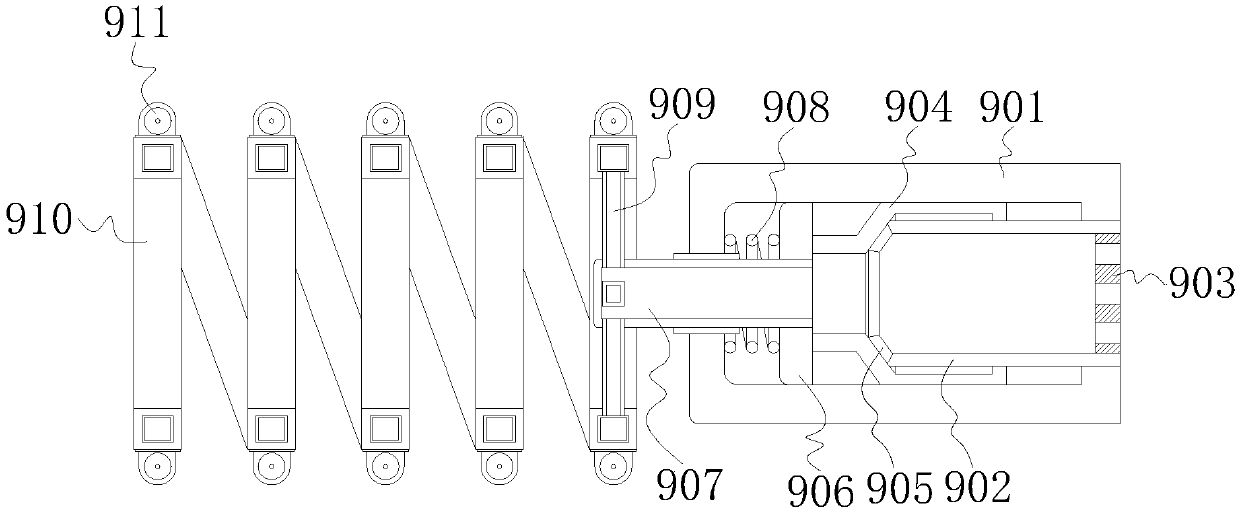

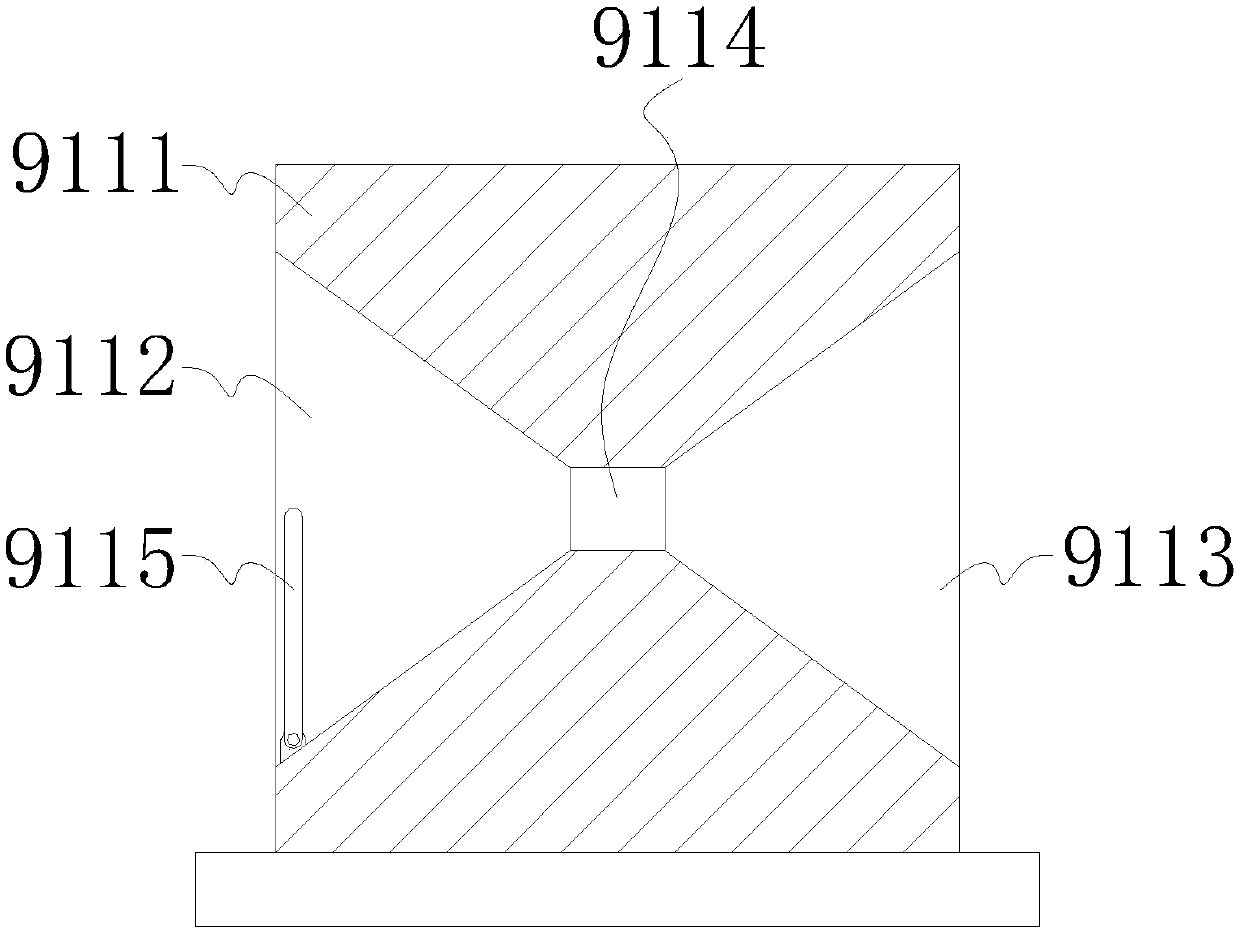

[0025] see Figure 1-3 , the present invention provides a technical solution: an aluminum bronze continuous casting furnace based on electromagnetic stirring and autonomous stirring, including a body 1, an electromagnetic stirrer 5, a driving motor 6, a tapered spiral strip 7, a bellows 8 and a trapping mechanism 9. The electromagnetic stirrer 5 is fixedly installed on the right side of the top of the body 1, and the output end of the electromagnetic stirrer 5 runs through the top of the body 1 and extends to the inner right wall of the body 1 close to the body 1, and the drive motor 6 is fixedly installed on the body 1 The middle part of the bottom, the middle part of the inner rear wall of the tapered spiral bar 7 bottom ring is connected to the output shaft of the drive motor 6 through a connecting rod, and the center of the circle of the tapered spiral bar 7 coincides with the center of circle of the drive motor 6 output shaft, and the drive motor 6 When the copper liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com