On-line Measurement and Compensation System for Geometric/Thermal Errors of CNC Machine Tools

一种补偿系统、数控系统的技术,应用在控制/调节系统、通用控制系统、测量热量等方向,能够解决无法实现在机测量与补偿、成本高、操作复杂等问题,达到快速高效测试、提高良品率和效率、提高加工精度和精度稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

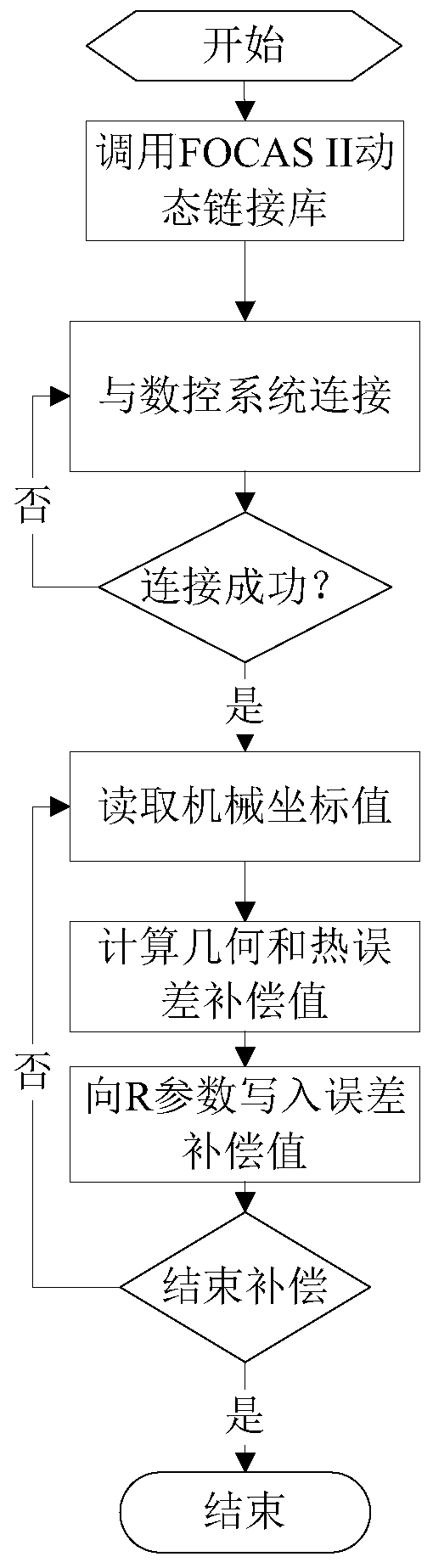

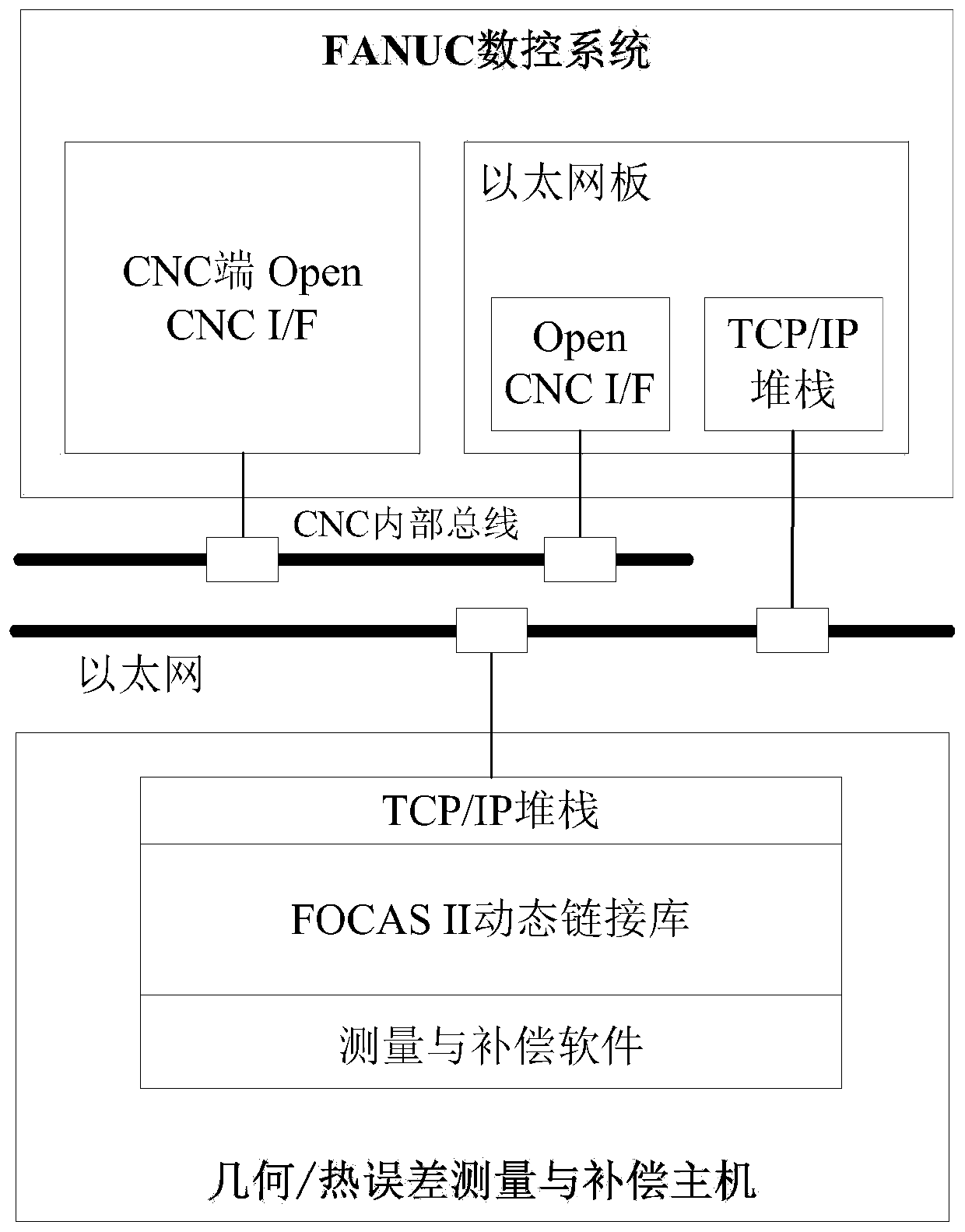

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, taking a certain type of vertical machining center equipped with FANUC 0i MD numerical control system as an example.

[0036] The basic information of the machine tool is: the maximum strokes of the X-axis, Y-axis and Z-axis are 710mm, 500mm and 350mm respectively, and their maximum feed speeds are 32m / min, 32m / min and 30m / min respectively; the maximum spindle speed is 15000r / min.

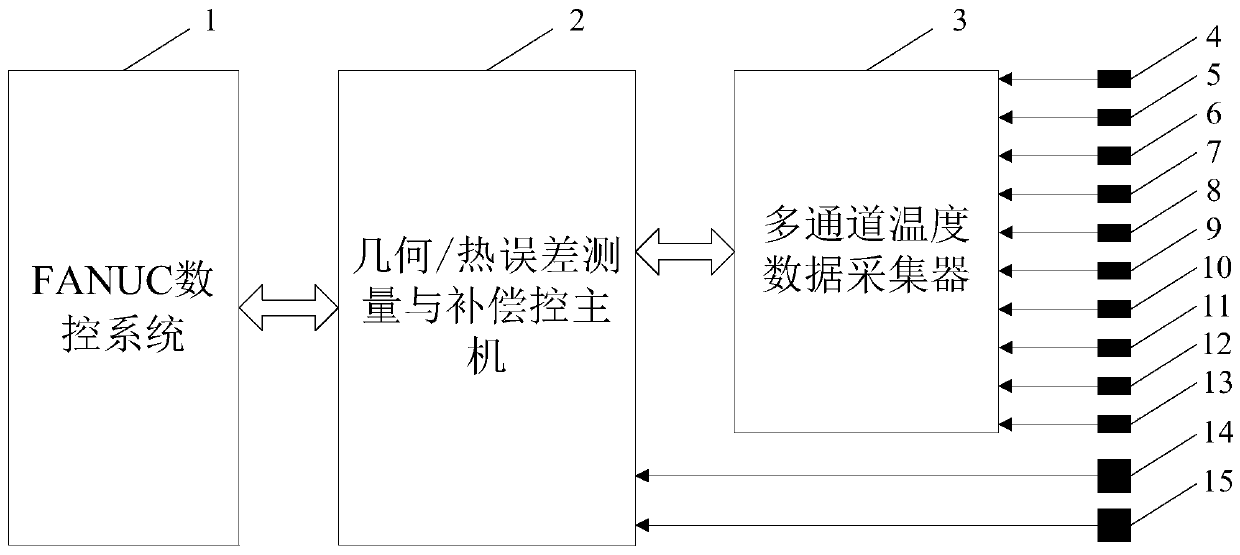

[0037] The hardware of the present invention such as figure 1 As shown, it includes unidirectional acceleration sensors 14 and 15, digital IC type high-precision temperature sensors 4-13, multi-channel temperature data collector 3 and geometric / thermal error measurement and compensation host 2. The connection and communication methods of each hardware are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com