Combined type axial rotating pulsating heat pipe grinding wheel and preparation method thereof

A technology of pulsating heat pipes and axial rotation, which is applied in bonded grinding wheels, manufacturing tools, metal processing equipment, etc. It can solve residual stress and micro-cracked grinding wheel blockage, it is difficult for coolant to enhance heat transfer, and the cooling effect of coolant is poor, etc. problems, to improve the life of the grinding wheel, avoid grinding burns, and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

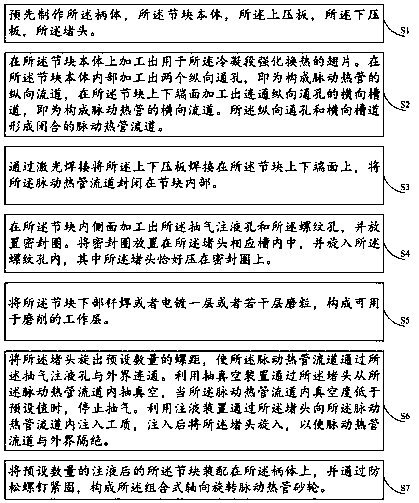

[0037] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

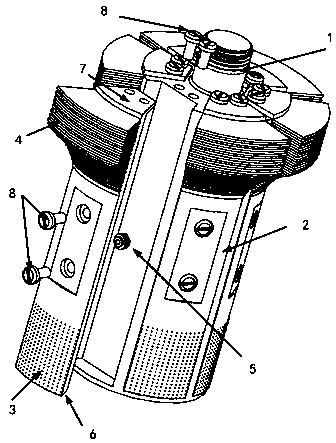

[0038] see Figure 2 to Figure 6 . A combined axially rotating pulsating heat pipe grinding wheel provided by the present invention includes a shank body 1, a grinding wheel segment 2, a plug 5, a vacuum injection hole 9, and other related accessories and structures.

[0039] Heat exchange fins 4 for strengthening heat exchange in the condensation section are processed on the outside of the grinding wheel segment 2 .

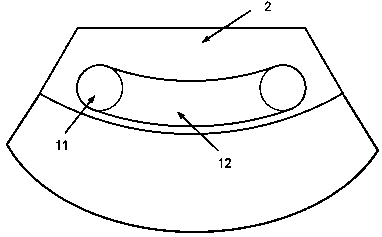

[0040] Inside the grinding wheel segment 2 there is an axial straight channel 11 along the direction of the grinding wheel segment, which is the longitudinal flow channel constituting the flow channel 10 of the single-circuit pulsating heat pipe. The diameter of the round through hole is 3 mm, which belongs to the capillary tube, so that the working fluid in the pulsating heat pipe is mainly affected by capillary force and surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com