Board cutting machine

A technology of cutting machine and wood board, applied in the field of wood board processing, can solve the problems of dust affecting human health, difficult to control the advancing speed of the cutting machine, burrs are easy to hurt people, etc., to avoid dust flying, avoid dust, and prevent moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

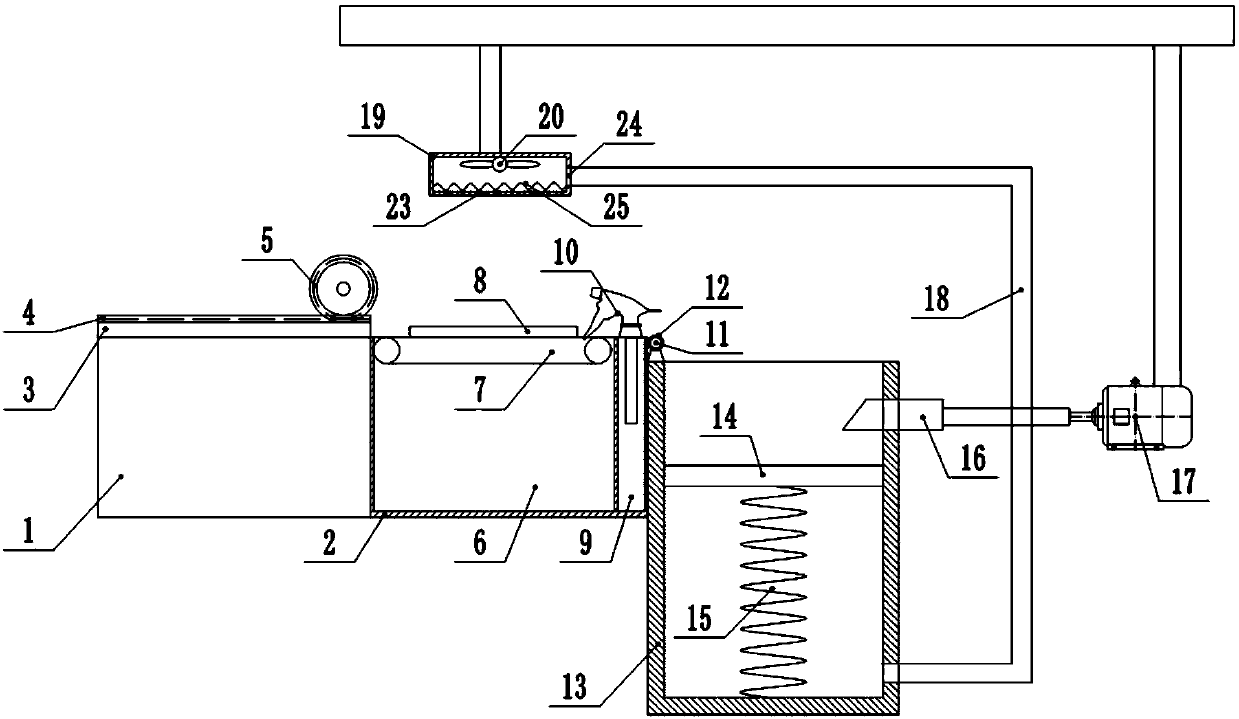

[0026] The reference signs in the accompanying drawings of the specification include: first workbench 1, second workbench 2, limit baffle 3, rack 4, gear 5, cavity 6, conveyor belt 7, grinding wheel 8, water tank 9, spray Kettle 10, guide wheel 11, fifth motor 12, storage box 13, receiving plate 14, spring 15, wedge 16, cylinder 17, pipe 18, oven 19, fan 20, air outlet 23, air inlet 24, heating wire 25 .

[0027] Example figure 1 The wood cutting machine shown includes two workbenches, the two workbenches include the first workbench and the second workbench. Mechanism, grinding mechanism, storage mechanism, and a drying mechanism is arranged above the grinding mechanism.

[0028] The cutting mechanism includes a limit baffle 3 that is slidably connected to the front and rear sides of the first worktable 1. The limit baffle 3 is fixedly connected with a rack 4, and the right end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com