A kind of method utilizing high-speed emulsification shearing to prepare flocculant

A technology of emulsifying shearing and flocculant, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of chemical production, limited adjustment of polymerization degree, etc., to achieve the effects of stable properties, low cost and high dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a flocculant by high-speed emulsification and shearing, comprising the following steps: high-speed shearing, stirring, dispersion and homogenization of the reaction base material, continuous addition of an alkaline regulator according to the ratio of process materials, and continuous emulsification and shearing after the addition is complete. The flocculant was prepared by stirring reaction, wherein the shear stirring high tangential velocity was 38m / s, the reaction temperature was 75°C, the mass ratio of base material to alkaline regulator was 3:1, and the flow rate of alkaline regulator was 0.05m 3 / h, shear stirring reaction time is 2h.

[0030] Illustrate with the industrial grade polyaluminum chloride (PAC) product as an example:

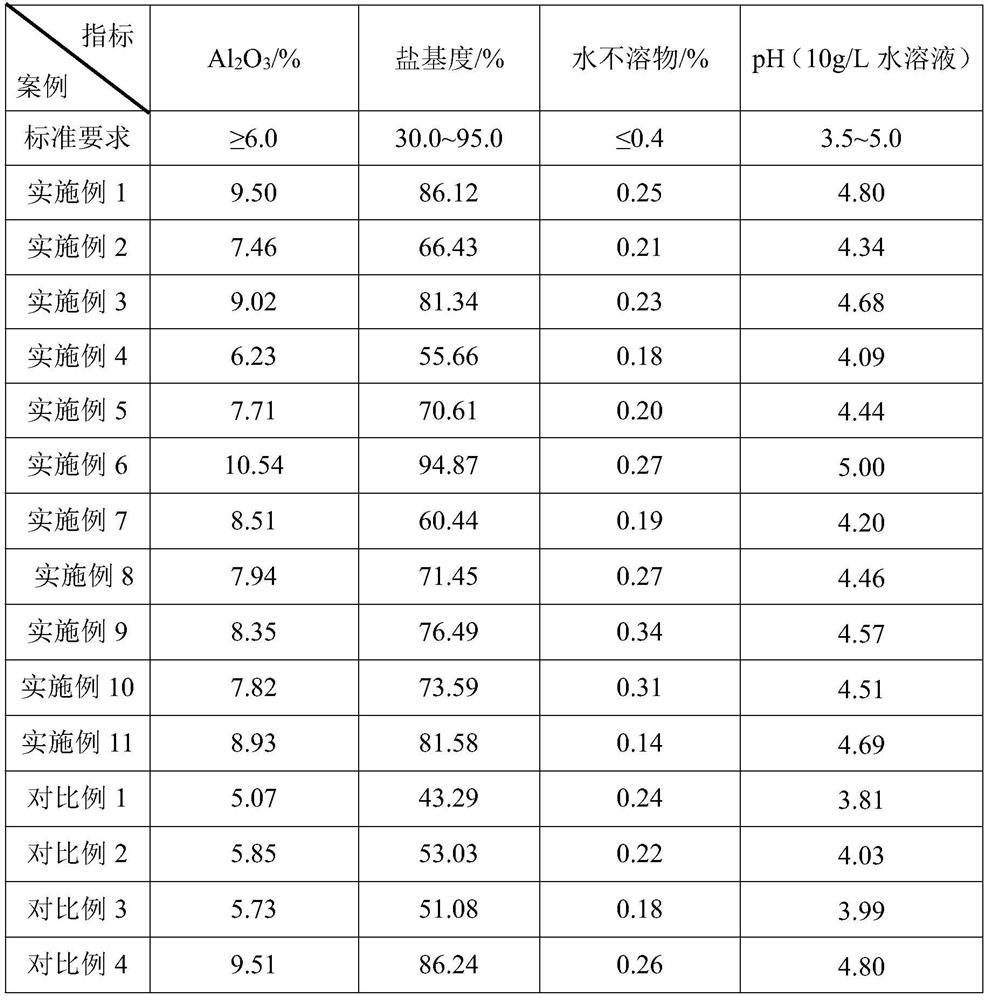

[0031] Among them, the base aluminum liquid is aluminum chloride, and the main performance indicators are shown in Table 1 below:

[0032]The main performance index of table 1 embodiment 1 base material aluminum c...

Embodiment 2

[0038] A method for preparing a flocculant by high-speed emulsification and shearing, comprising the following steps: high-speed shearing, stirring, dispersion and homogenization of the reaction base material, continuous addition of an alkaline regulator according to the ratio of process materials, and continuous emulsification and shearing after the addition is complete. The flocculant was prepared by stirring reaction, wherein the shear stirring high tangential velocity was 30m / s, the reaction temperature was 75°C, the mass ratio of base material to alkaline regulator was 3:1, and the flow rate of alkaline regulator was 0.05m 3 / h, shear stirring reaction time is 2h.

[0039] Wherein base material and alkaline conditioner are identical with embodiment 1.

Embodiment 3

[0041] A method for preparing a flocculant by high-speed emulsification and shearing, comprising the following steps: high-speed shearing, stirring, dispersion and homogenization of the reaction base material, continuous addition of an alkaline regulator according to the ratio of process materials, and continuous emulsification and shearing after the addition is complete. The flocculant was prepared by stirring reaction, wherein the shear stirring high tangential velocity was 40m / s, the reaction temperature was 75°C, the mass ratio of base material to alkaline regulator was 3:1, and the flow rate of alkaline regulator was 0.05m 3 / h, shear stirring reaction time is 2h.

[0042] Wherein base material and alkaline conditioner are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com