Method for promoting anaerobic digestion sludge heavy metal stability

An anaerobic digestion, heavy metal technology, applied in chemical instruments and methods, biological sludge treatment, water/sludge/sewage treatment, etc., to achieve rapid fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

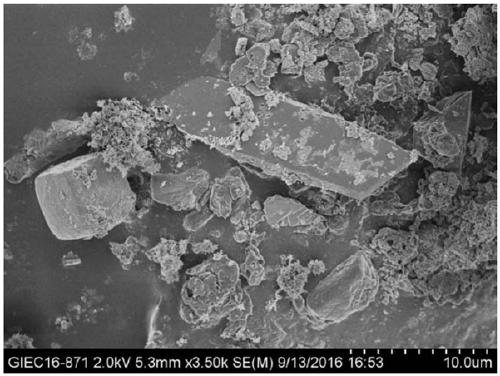

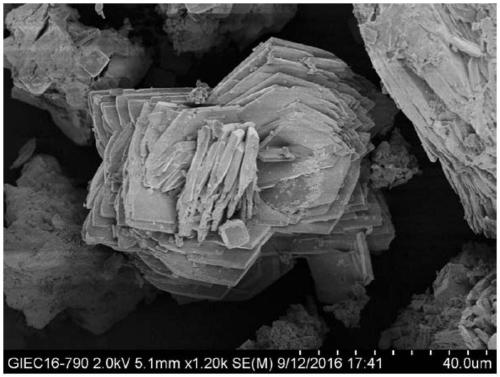

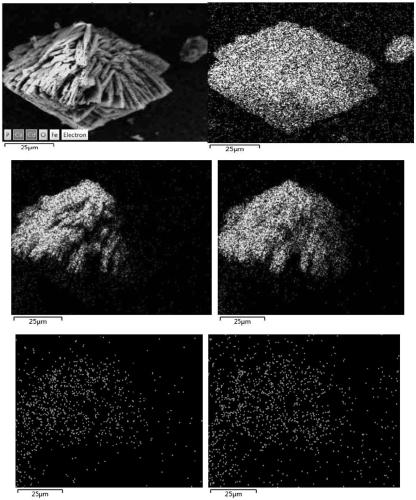

Image

Examples

Embodiment 1

[0028] (1) Adjust the TCOD of anaerobic digested sludge to 30000mg / L, pH to about 7.0, pass N 2 When the oxidation-reduction potential (ORP) is less than -300mV (usually 30min). Then, at N 2 Under the protection of the sludge, the specification is 500mL, and the working volume is an anaerobic reaction bottle of 300mL. At the same time, in the anaerobic reaction bottle, every 1L of anaerobic digested sludge is added with 1% v / v iron-reducing bacteria agent ( The concentration of effective viable bacteria in the iron-reducing bacteria agent is ≥6×10 9 CFU / mL), cap the bottle tightly and seal it with parafilm. The treatment not inoculated with iron-reducing bacteria was used as the control.

[0029] The above anaerobic digested sludge was collected from the return sludge of the secondary settling tank of a sewage plant (the inoculation sludge used in this experiment was fresh activated sludge from a sewage treatment plant), and the retrieved sludge was first filtered through a...

Embodiment 2

[0039] (1) Adjust the TCOD of anaerobic digested sludge to 20000mg / L, pH to about 7.0, pass N 2When the oxidation-reduction potential (ORP) is less than -300mV (usually 30min). Then, at N 2 Under the protection of the sludge, the specification is 500mL, and the working volume is an anaerobic reaction bottle of 300mL. At the same time, in the anaerobic reaction bottle, every 1L of anaerobic digested sludge is added with 2% v / v iron reducing bacteria agent ( The concentration of effective viable bacteria in the iron-reducing bacteria agent is ≥6×10 9 CFU / mL), cap the bottle tightly and seal it with parafilm. The treatment not inoculated with iron-reducing bacteria was used as the control.

[0040] The above-mentioned anaerobic digested sludge was collected from the return sludge of the secondary settling tank of a sewage plant. The retrieved sludge was first filtered through a 40-mesh screen and then settled for 24 hours. Save the concentrated sludge. The basic physical and...

Embodiment 3

[0049] (1) Adjust the TCOD of anaerobic digested sludge to 10000mg / L, pH to about 7.0, pass N 2 When the oxidation-reduction potential (ORP) is less than -300mV (usually 30min). Then, at N 2 Under the protection of the sludge, the specification is 500mL, and the working volume is an anaerobic reaction bottle of 300mL. At the same time, in the anaerobic reaction bottle, every 1L of anaerobic digested sludge is added with 2% v / v iron reducing bacteria agent ( The concentration of effective viable bacteria in the iron-reducing bacteria agent is ≥6×10 9 CFU / mL), cap the bottle tightly and seal it with parafilm. The treatment not inoculated with iron-reducing bacteria was used as the control.

[0050] The above-mentioned anaerobic digested sludge was collected from the return sludge of the secondary settling tank of a sewage plant. The retrieved sludge was first filtered through a 40-mesh screen and then settled for 24 hours. Save the concentrated sludge. The basic physical an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com