Carbon fiber sea sand high performance concrete material and preparation method thereof

A high-performance concrete and carbon fiber technology, applied in the field of concrete materials, can solve the problems of shortening the service life of concrete structures, corrosion of steel bars, etc., to avoid the degradation and deterioration of salt water, improve earthquake resistance, and reduce heat transfer and thermal expansion coefficients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

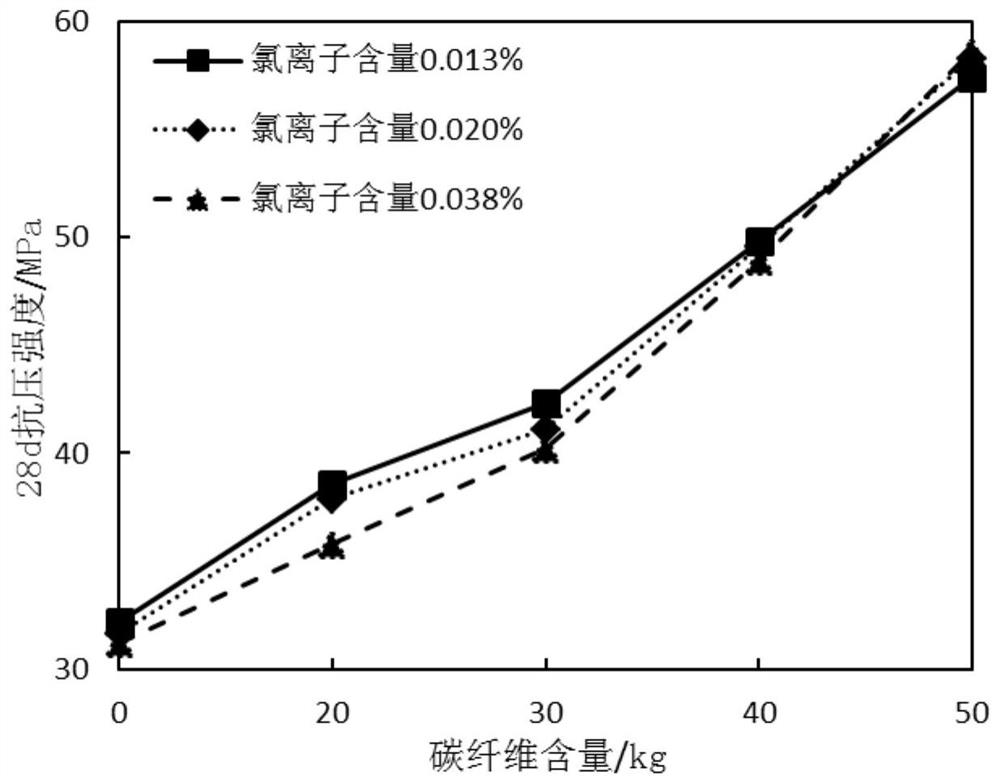

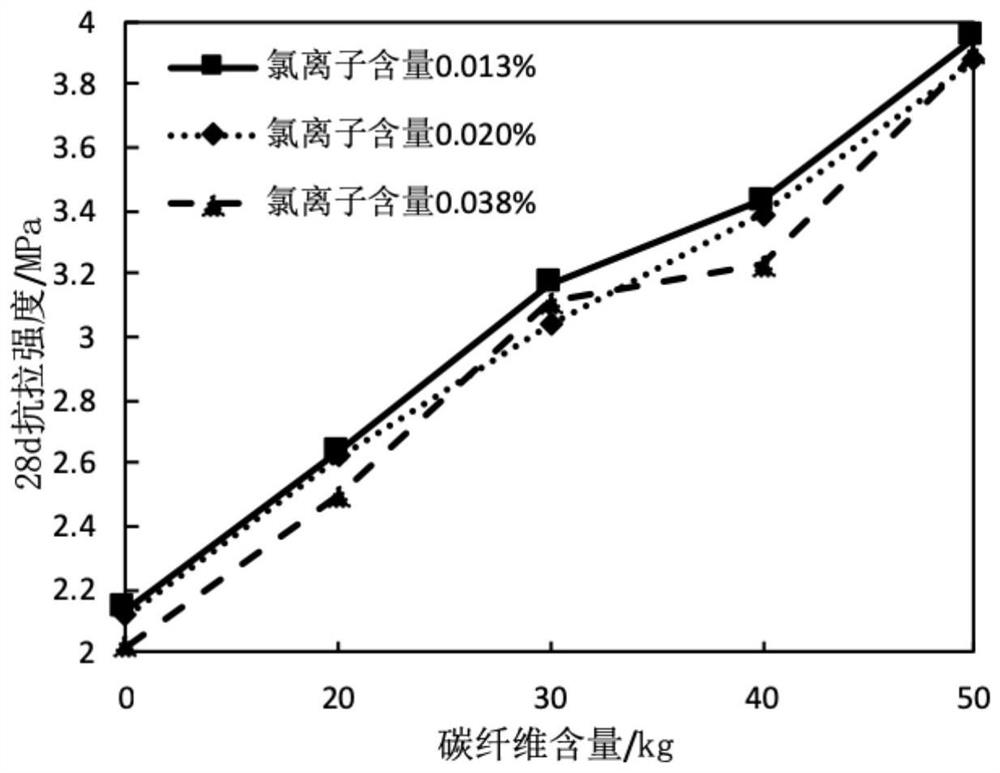

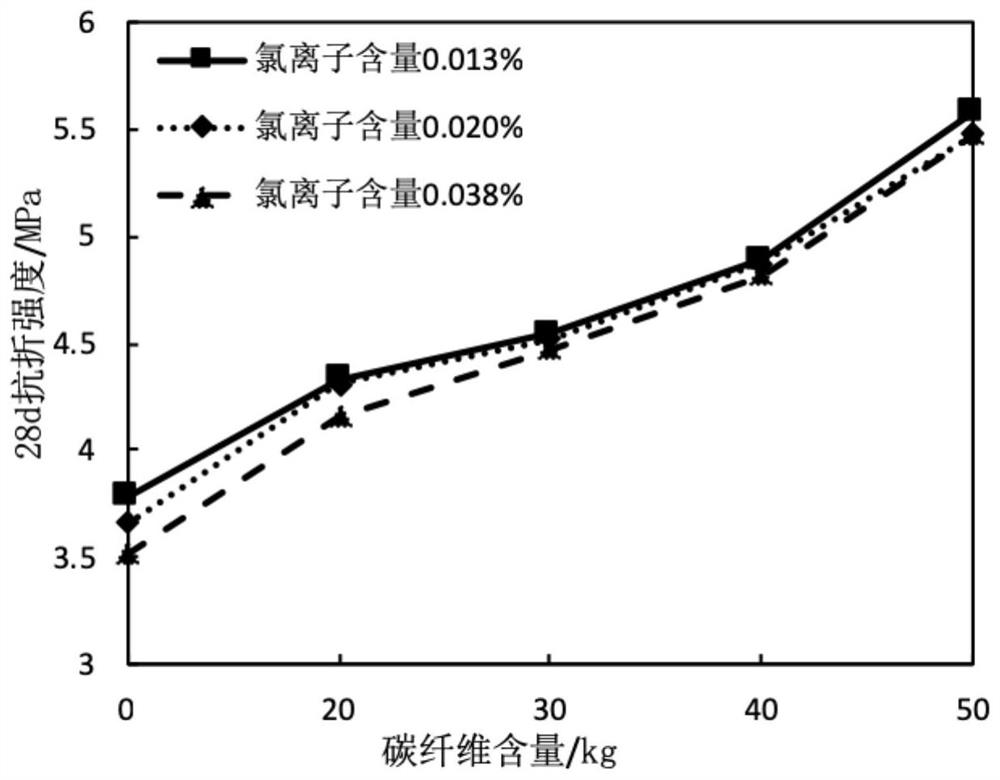

Embodiment 1

[0029] Weigh the following materials: 160kg of water, 450kg of Portland cement, 600kg of sea sand, 2.5kg of polycarboxylate superplasticizer, 20kg of carbon fiber, and 1400kg of stones. First, pour the stones into the mixer and then add sea sand for 2~3 minutes Mix until evenly mixed, then add cement to the evenly mixed stones and sea sand, and add water and water reducer during the mixing process of cement, stones, and sea sand and stir for 3~5 minutes until evenly mixed, and finally add carbon fiber to the dry mixed In the material, continue stirring for 3 minutes to obtain the carbon fiber sea sand high-performance concrete material of this embodiment. Among them, the sea sand in this embodiment adopts the sand in zone II, and the chloride ion content is 0.013%, and the shell content is 6%.

Embodiment 2

[0031] It is roughly the same as the above-mentioned embodiment 1, the difference is that the weighed weight of the carbon fiber in this embodiment is 30kg.

Embodiment 3

[0033] It is substantially the same as the above-mentioned embodiment 1, the difference is that the weighed weight of the carbon fiber in this embodiment is 40kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com