Water-based universal color paste and preparing method thereof

A color paste, water-based technology, applied in the direction of pigment paste, etc., can solve the problems of decreased coating performance, poor versatility, increased VOC, etc., and achieve the effect of improving surface affinity, strong applicability, and improving affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

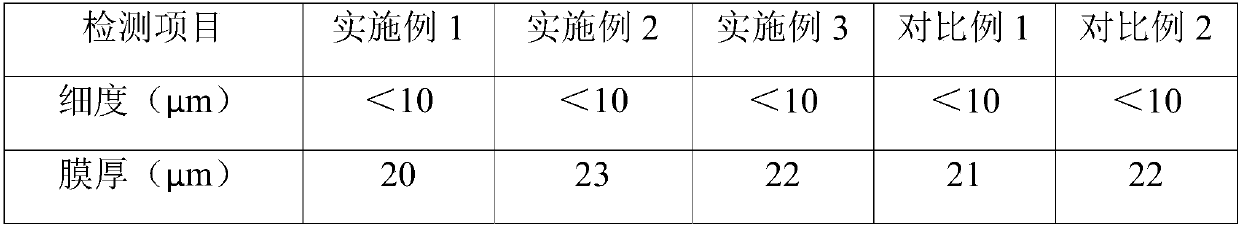

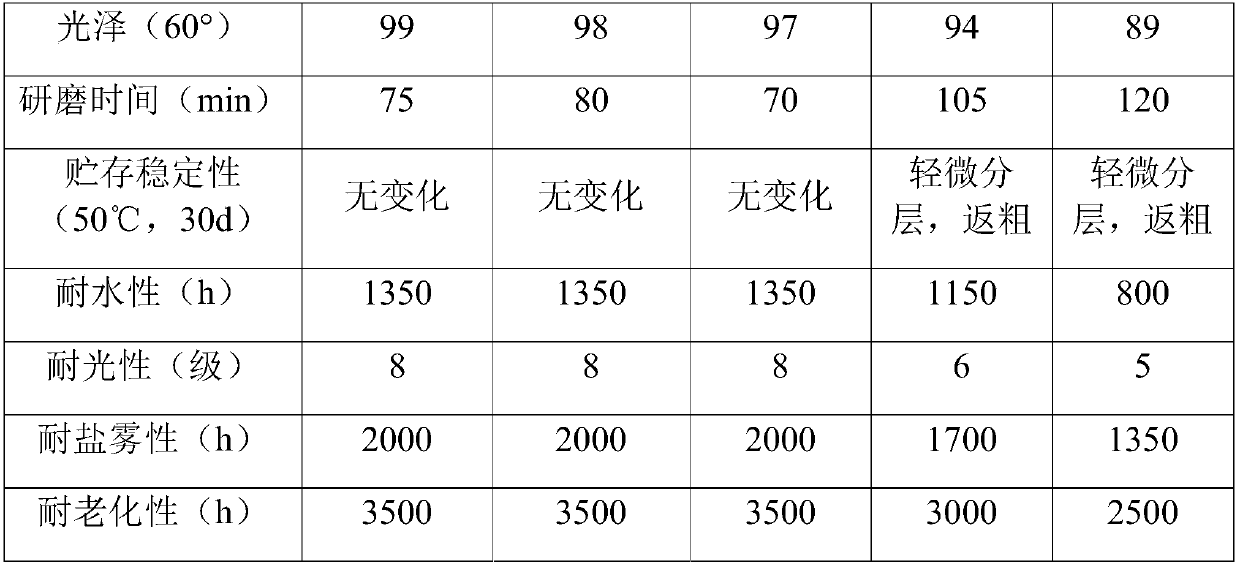

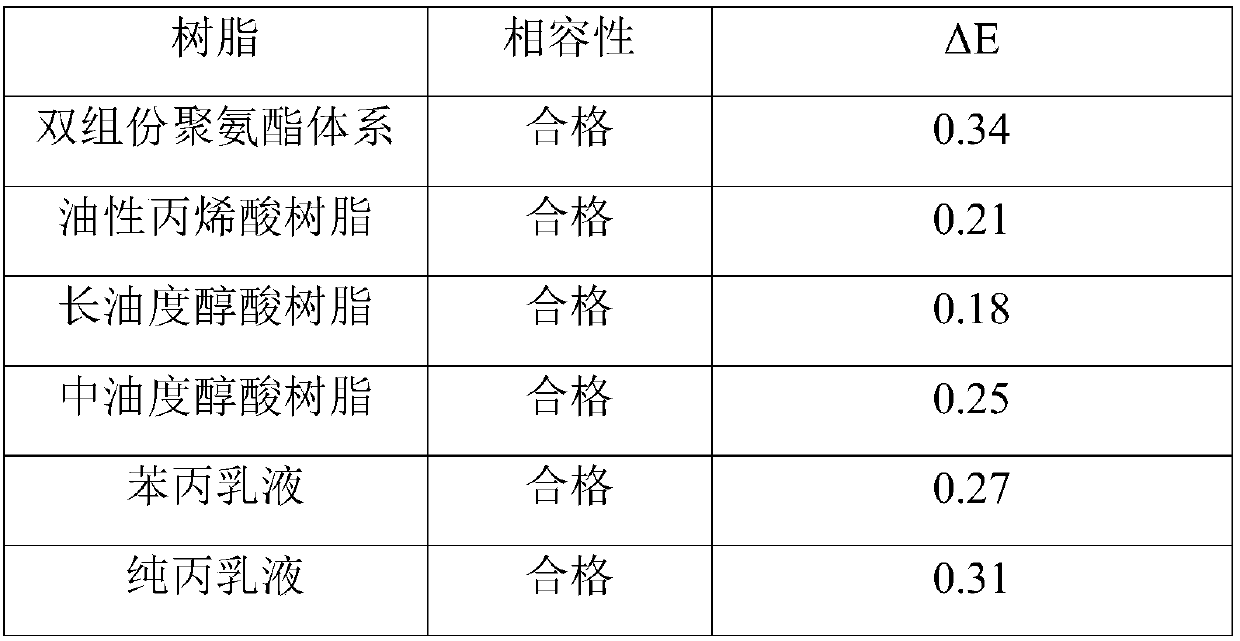

Examples

Embodiment 1

[0031] The embodiment of the present invention provides a water-based universal color paste, including the following raw material components in parts by weight: 5 parts of deionized water, 20 parts of acrylic modified polyurethane resin, 5 parts of glycerin, 8 parts of dispersant, and 0.1 part of defoamer , 0.3 parts of thickener, 0.5 parts of pH regulator, 1 part of small molecular weight wetting agent, 0.1 part of preservative and 50 parts of pigment.

[0032] The acrylic modified polyurethane resin is from Belgium Allnex VTW1262; the glycerol is 95% industrial grade glycerol produced by Shandong Asahi Ash Chemical Co., Ltd.; the dispersant is ZetaSperse 3800 dispersant of Evonik; the defoamer is BYK-011 of German BYK and Shanghai Liqi Chemical Additive Co., Ltd. L-101, wherein the mass ratio of BYK-011 and L-101 is 2:1; the thickener is Evonik Degussa's fumed silica R972 and BYK's BYK-420 polyurethane thickener The mixture of agent, wherein the mass ratio of fumed silica a...

Embodiment 2

[0038] A water-based universal color paste, comprising the following raw material components in parts by weight: 20 parts of deionized water, 30 parts of acrylic modified polyurethane resin, 3 parts of glycerin, 5 parts of dispersant, 0.5 parts of defoamer, 0.4 parts of thickener 0.1 part of pH regulator, 2 parts of small molecular weight wetting agent, 0.3 part of preservative and 25 parts of pigment.

[0039] The acrylic modified polyurethane resin is from Belgium Allnex 35W; the defoamer is BYK-011 from BYK Germany and L-101 from Shanghai Liqi Chemical Auxiliary Co., Ltd., wherein the mass ratio of BYK-011 and L-101 is 3:1; the thickener is Evonik The mixture of fumed silica R972 of Gusai and BYK-420 polyurethane thickener of BYK, wherein the mass ratio of fumed silica and polyurethane thickener is 1:2; the pigment is R179; the rest of the components are mixed with Example 1 is the same.

[0040] The preparation steps of above-mentioned water-based universal color paste ...

Embodiment 3

[0045] A water-based universal color paste, comprising the following raw material components in parts by weight: 15 parts of deionized water, 15 parts of acrylic modified polyurethane resin, 2 parts of glycerin, 10 parts of dispersant, 0.3 parts of defoamer, 0.5 parts of thickener 1 part, 1 part of pH regulator, 3 parts of small molecular weight wetting agent, 0.5 part of preservative and 35 parts of pigment.

[0046] The defoamer is BYK-011 from BYK of Germany and L-101 from Shanghai Liqi Chemical Auxiliary Co., Ltd., wherein the mass ratio of BYK-011 and L-101 is 4:1; the thickener is Evonik Degussa The mixture of fumed silica R972 and Bi Ke's BYK-420 polyurethane thickener, wherein the mass ratio of fumed silica and polyurethane thickener is 1:3; the pigment is PG36; all the other components are the same as in the examples 1 is the same.

[0047] The preparation steps of above-mentioned water-based universal color paste are as follows:

[0048] Step a, weigh each componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com