Passivated lime reverse passivating process

A technology of lime technology, applied in the field of passivation lime reverse passivation technology, can solve the problems of outstanding water absorption characteristics, unfavorable for product transportation, storage, unfavorable for pneumatic transportation, etc., achieve good product use effect, improve passivation efficiency, Good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

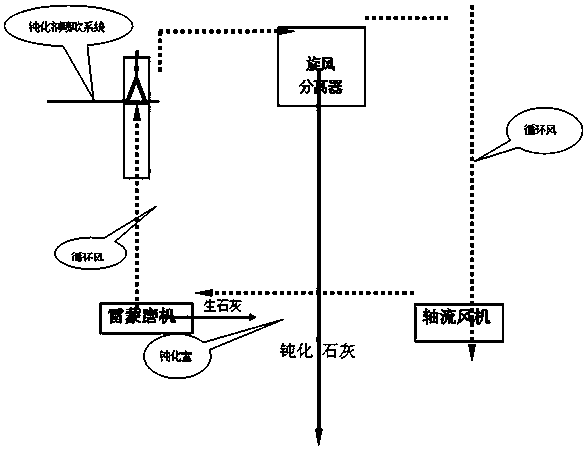

[0052] Such as figure 1 As shown, a passivated lime reverse passivation process, which includes quicklime grinding, two-fluid atomization injection, reverse injection, final passivation steps,

[0053] 1), quicklime grinding

[0054] The grinding of quicklime is composed of a mill-air separation system, and the specific process features are as follows:

[0055](1) Select raw lime with a particle size of 20-40mm, and send it to the Raymond mill for grinding through the feeding and conveying mechanism; select the excitation electric vibration feeder for feeding, the frequency is adjustable from 0-50Hz, and the feeding amount is 0-12t / h;

[0056] (2) Set the frequency of the mill separator to be adjustable from 0-50Hz, the passing rate of 325 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com