Sewage water body refuse type cement and method of preparing the same

A mud and sewage technology, applied in cement production, clay products, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]Its preferred and practical preparation method is: add appropriate amount of water to the raw materials of the above-mentioned components by weight, process them into balls in a mixer molding machine (or other mixer), and dry them naturally to form raw balls; then put the raw balls in In the drying and roasting kiln (such as tunnel kiln, etc.), it is first dried in a low-temperature drying belt at 100-200°C for 20-40 minutes, then roasted in a high-temperature baking belt at 500-1000°C for 50-100 minutes, and then cooled naturally after leaving the kiln. The mature material ball is the sewage cement slag product; finally, the sewage cement slag product and cement clinker are mixed together at a ratio of 30% to 5%: 70% to 95% and ground into powder, which is the sewage cement slag cement. Sewage cement slag products can be ground into powder and then mixed with cement at a ratio of 30% to 5%:70% to 95% to form sewage cement slag cement. The above-mentioned roasting temper...

Embodiment 2

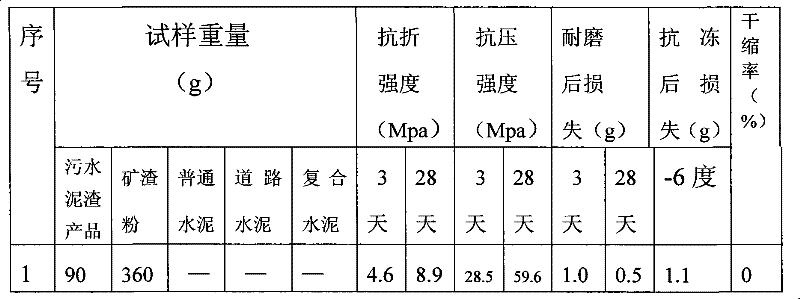

[0044] The sewage cement slag cement mixed with the slag powder of the existing commercial cementing material and the sewage cement slag product in a certain proportion is used as the cementitious material. For performance comparison, the results are shown in Table 2:

[0045] Table 2: Performance comparison between sewage cement slag cement and several commonly used cements

[0046]

[0047]

[0048] It can be seen from Table 2 that the sewage cement slag cement that is formed by mixing a certain proportion of sewage cement products into the existing commercial slag powder is used as a cementitious material, and its flexural strength, compressive strength and wear resistance, frost resistance, The drying shrinkage performance is higher than that of ordinary cement, road cement and composite cement not mixed with sewage cement slag products. It can be seen that it can be used in place of ordinary cement, road cement and composite cement.

Embodiment 3

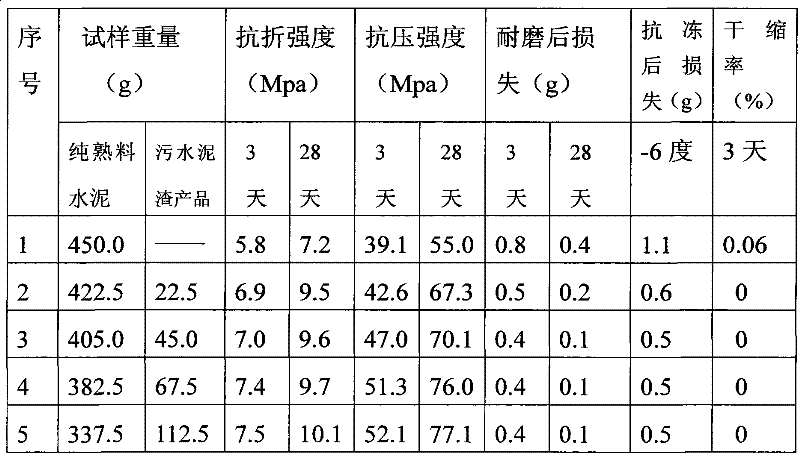

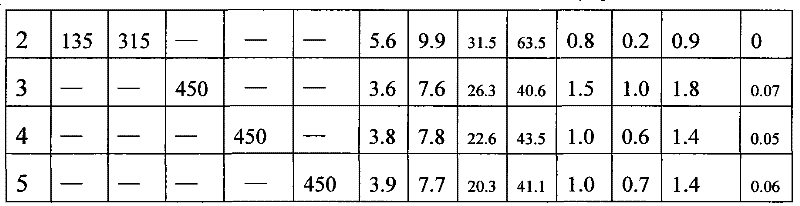

[0050] Sewage cement slag cement (serial number 2-5 in the table) mixed by adding a certain proportion of sewage cement slag products into the commercial slag cement is used as the cementitious material and commercial slag cement (serial number 1 in the table) is used as the glue respectively. Concrete materials were tested and compared in terms of physical properties such as strength, wear resistance, frost resistance, and dry shrinkage according to the ISO relevant cement physical property test standards. The test results are shown in Table 3:

[0051] Table 3: Performance comparison between sewage cement slag cement and slag cement with different mixing ratios

[0052]

[0053] It can be seen from Table 3 that the flexural strength, compressive strength, abrasion resistance, frost resistance, dry shrinkage and other properties of the sewage cement slag cement mixed with a certain proportion of sewage cement products in the existing commercial slag cement are higher than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com