Preparation method of high-dispersion modified nano zinc oxide

A nano-zinc oxide and nano-tin antimony oxide technology is applied in the field of preparation of highly dispersed modified nano-zinc oxide, which can solve the problems of poor safety performance, difficult to uniformly disperse, easy to reduce stability, etc., so as to improve the uniformity of structure distribution. , good safety performance, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a preparation method of highly dispersed modified nano-zinc oxide, the specific preparation steps are as follows:

[0026] Step 1: adding nano-zinc oxide into the modified disperser for 30 minutes to obtain modified nano-zinc oxide;

[0027] Step 2: adding the modified nano-zinc oxide prepared in step 1 to the modified immersion solution a for soaking treatment for 20 minutes, and performing ultrasonic oscillation treatment while soaking to obtain soaked modified nano-zinc oxide A;

[0028] Step 3: adding the soaked modified nano-zinc oxide A prepared in step 2 into the modified immersion solution b for soaking treatment for 20 minutes, and performing ultrasonic oscillation treatment while soaking to obtain soaked modified nano-zinc oxide B;

[0029] Step 4: Add the soaked modified nano-zinc oxide B prepared in step 3 to the modified immersion solution c for soaking treatment for 20 minutes, and perform ultrasonic oscillation treatment while soaki...

Embodiment 2

[0038] The difference from Example 1 is that the treatment was performed for 40 minutes in Step 1, and 30 minutes in Step 2, Step 3 and Step 4.

Embodiment 3

[0040] All different from Examples 1-2, the treatment was performed for 35 minutes in Step 1, and 25 minutes in Step 2, Step 3 and Step 4.

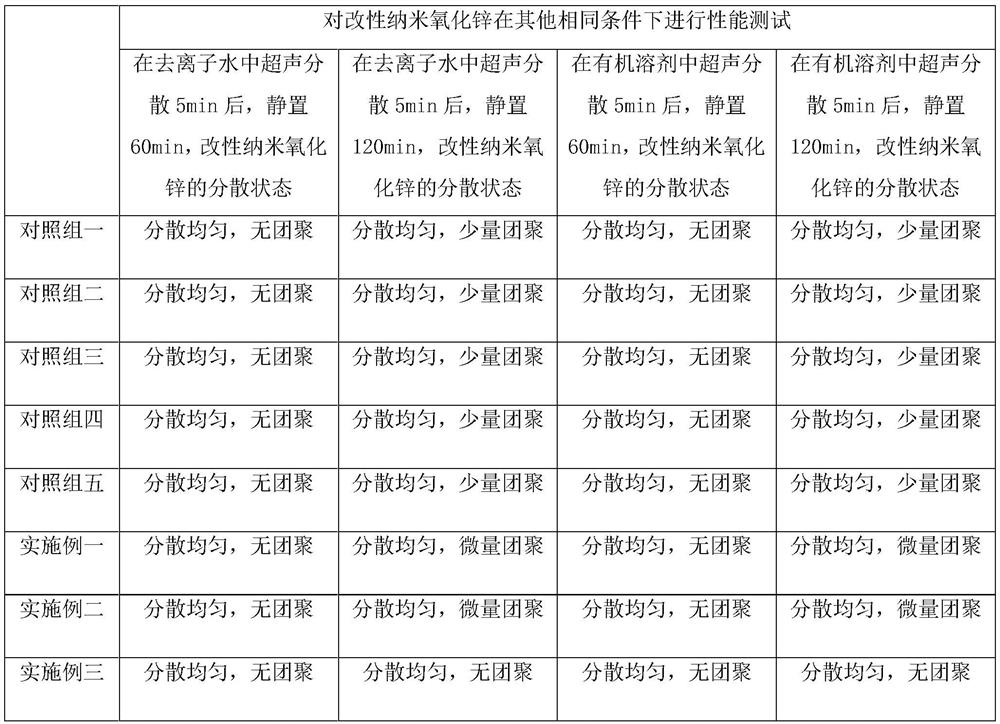

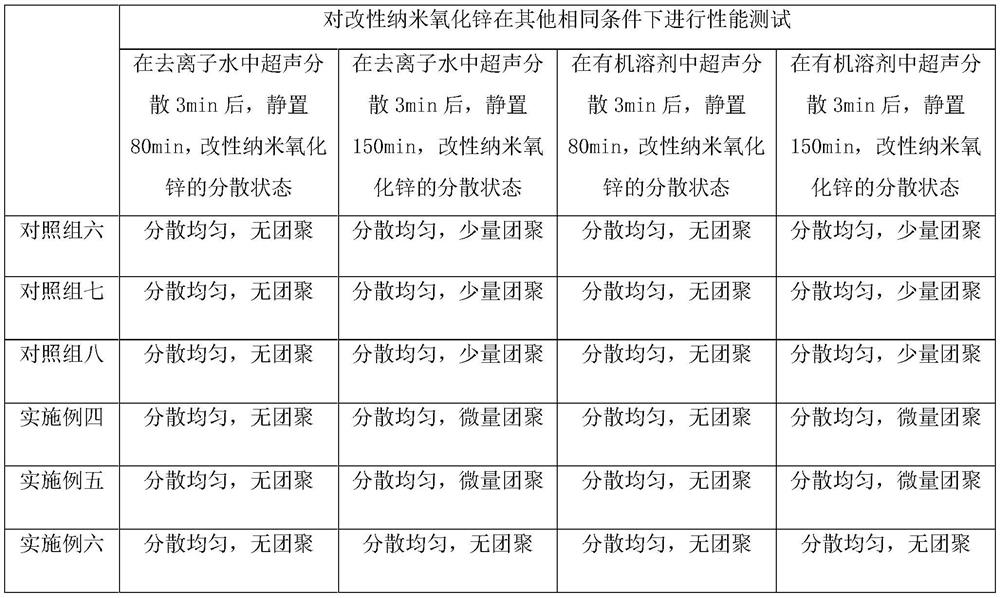

[0041]Get respectively the modified nano-zinc oxide prepared by above-mentioned embodiment 1-3 and the modified nano-zinc oxide of control group one, the modified nano-zinc oxide of control group two, the modified nano-zinc oxide of control group three, the control group The modified nano-zinc oxide of four, the modified nano-zinc oxide of the matched group five, the modified nano-zinc oxide of the matched group one does not have the operation in step one compared with the embodiment, the modified nano-zinc oxide of the matched group two and the implementation Compared with the operation in step 2, the modified nano-zinc oxide of the control group 3 does not have the operation in the step 3 compared with the embodiment, and the modified nano-zinc oxide of the control group 4 does not have the operation in the step 4 compared with the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com