A kind of preparation method of MNO2/carbon fiber tube composite electrode material

A carbon fiber tube and composite electrode technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of long time and reduce material synthesis efficiency, and achieve simple steps, short synthesis time and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In this embodiment, 33mg carbon fiber tube, 17mg KMnO 4 Add it to 20ml of deionized water successively, ultrasonically disperse for 10min, then transfer it to the reaction bottle, then put the reaction bottle into a microwave synthesis instrument, set the temperature at 185°C, and the reaction time is 10min; after the reaction, the obtained sample is centrifuged ( 6000rpm) were collected, washed twice with deionized water and ethanol, and dried at 60°C for 12h to prepare the obtained MnO 2 / carbon fiber tube composite electrode material.

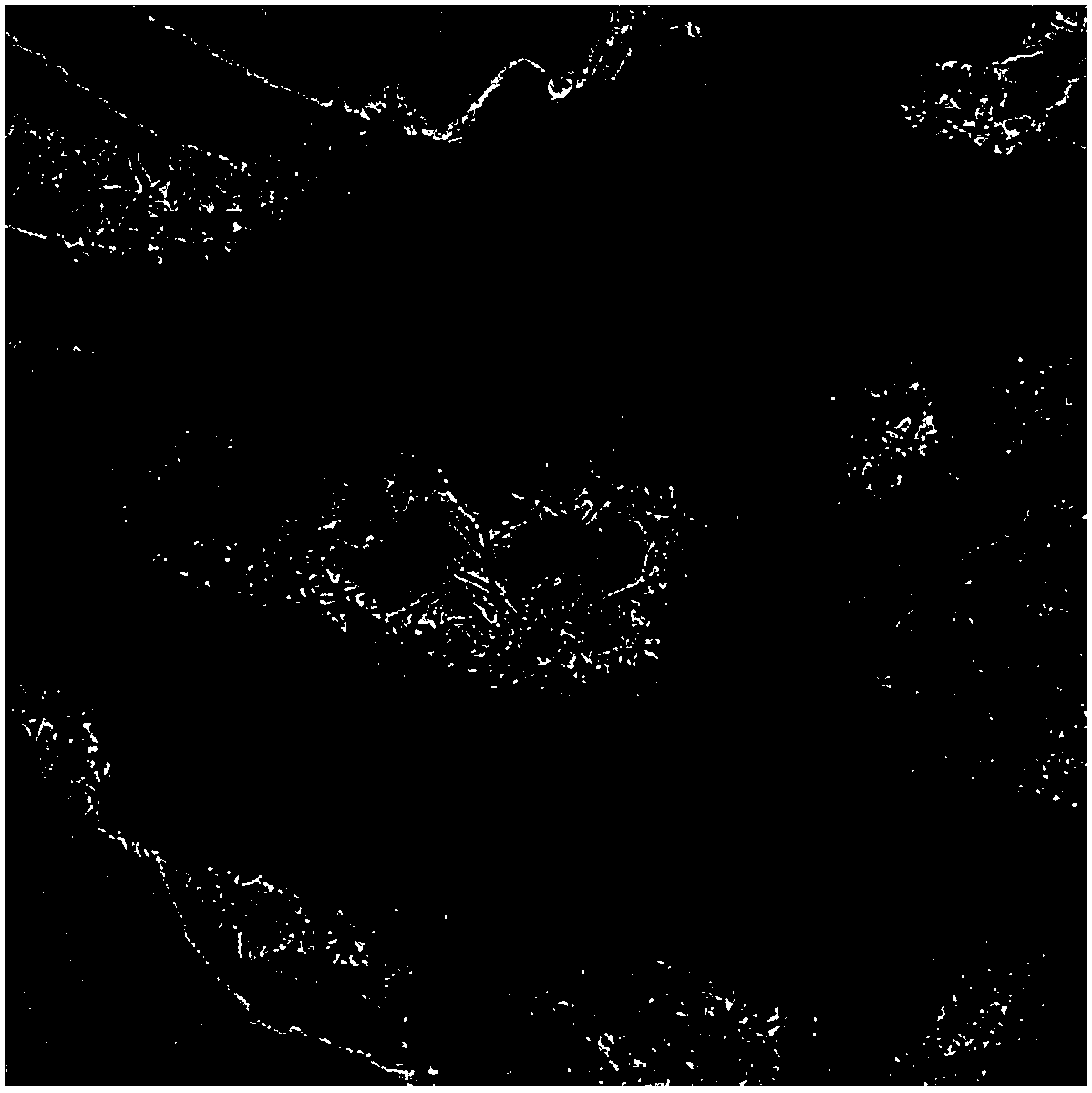

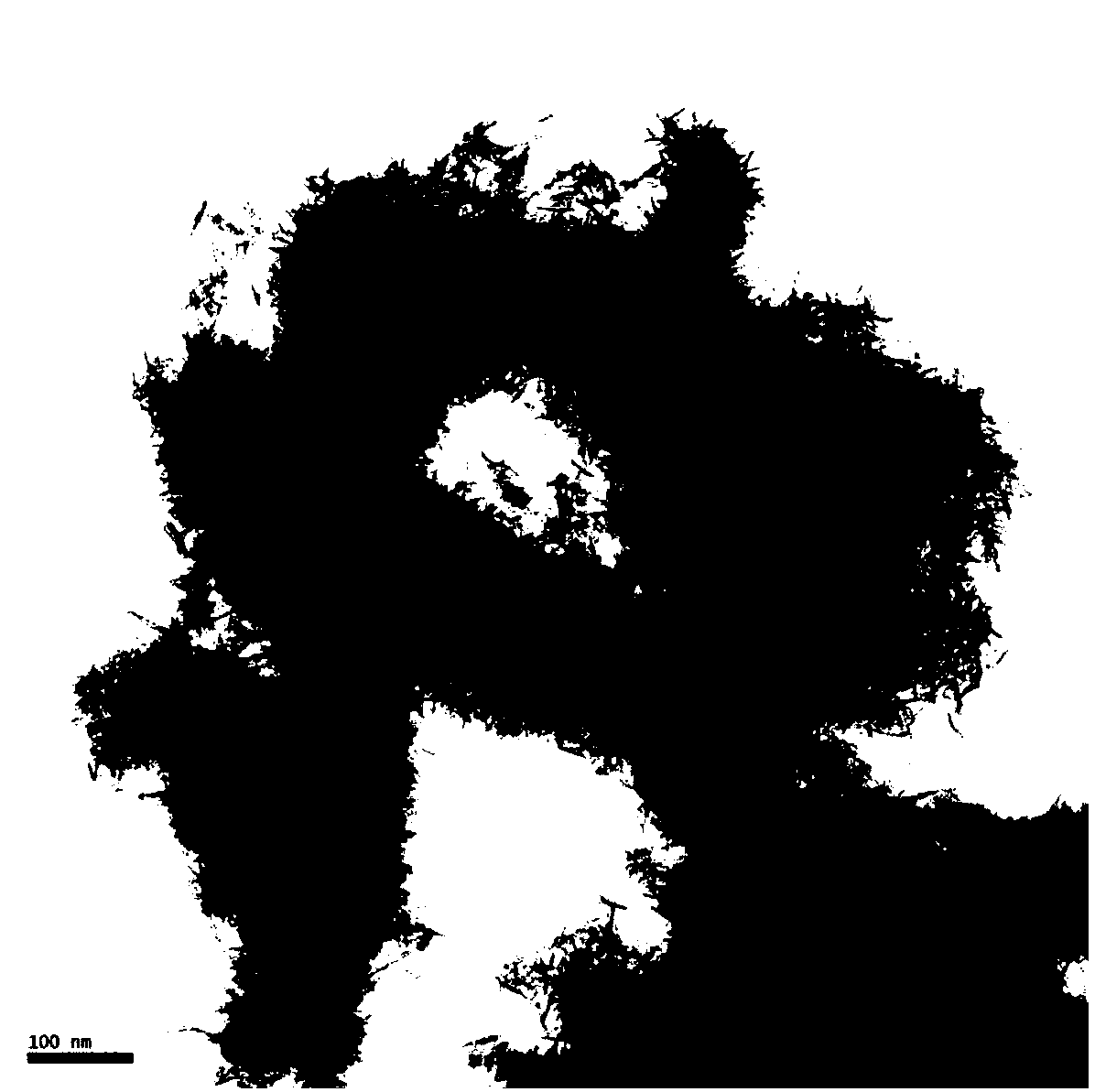

[0017] This embodiment is to the prepared MnO 2 / Carbon fiber tube composite electrode material for TEM characterization, such as figure 1 Shown, MnO 2 It is a nanorod structure with a diameter of 6-8nm and a length of 20-70nm, which is evenly attached to the surface of the carbon fiber tube.

Embodiment 2

[0019] In this embodiment, 33mg carbon fiber tube, 34mg KMnO 4 Add it to 20ml of deionized water successively, ultrasonically disperse for 10min, then transfer it to the reaction bottle, then put the reaction bottle into a microwave synthesis instrument, set the temperature at 185°C, and the reaction time is 10min; after the reaction, the obtained sample is centrifuged ( 6000rpm) were collected, washed twice with deionized water and ethanol in turn, and dried at 60°C for 12h to prepare MnO 2 / carbon fiber tube composite electrode material.

[0020] This embodiment is to the prepared MnO 2 / Carbon fiber tube composite electrode material for TEM characterization, such as figure 1 Shown, MnO 2 It is a nanorod structure with a diameter of 6-8nm and a length of 20-70nm, which is densely attached to the surface of the carbon fiber tube. Compared with the sample obtained in Example 1, MnO 2 content increased significantly.

[0021] The MnO that this embodiment will prepare 2 / ...

Embodiment 3

[0023] In this embodiment, 33mg carbon fiber tube, 51mg KMnO 4 Add it into 20ml deionized water successively, ultrasonically disperse it for 10min, then transfer it to the reaction bottle, then put the reaction bottle into the microwave synthesis instrument, set the temperature at 185°C, and the reaction time is 10min; after the reaction, the obtained sample is centrifuged ( 6000rpm) were collected, washed twice with deionized water and ethanol in turn, and dried at 60°C for 12h to prepare MnO 2 / carbon fiber tube composite electrode material.

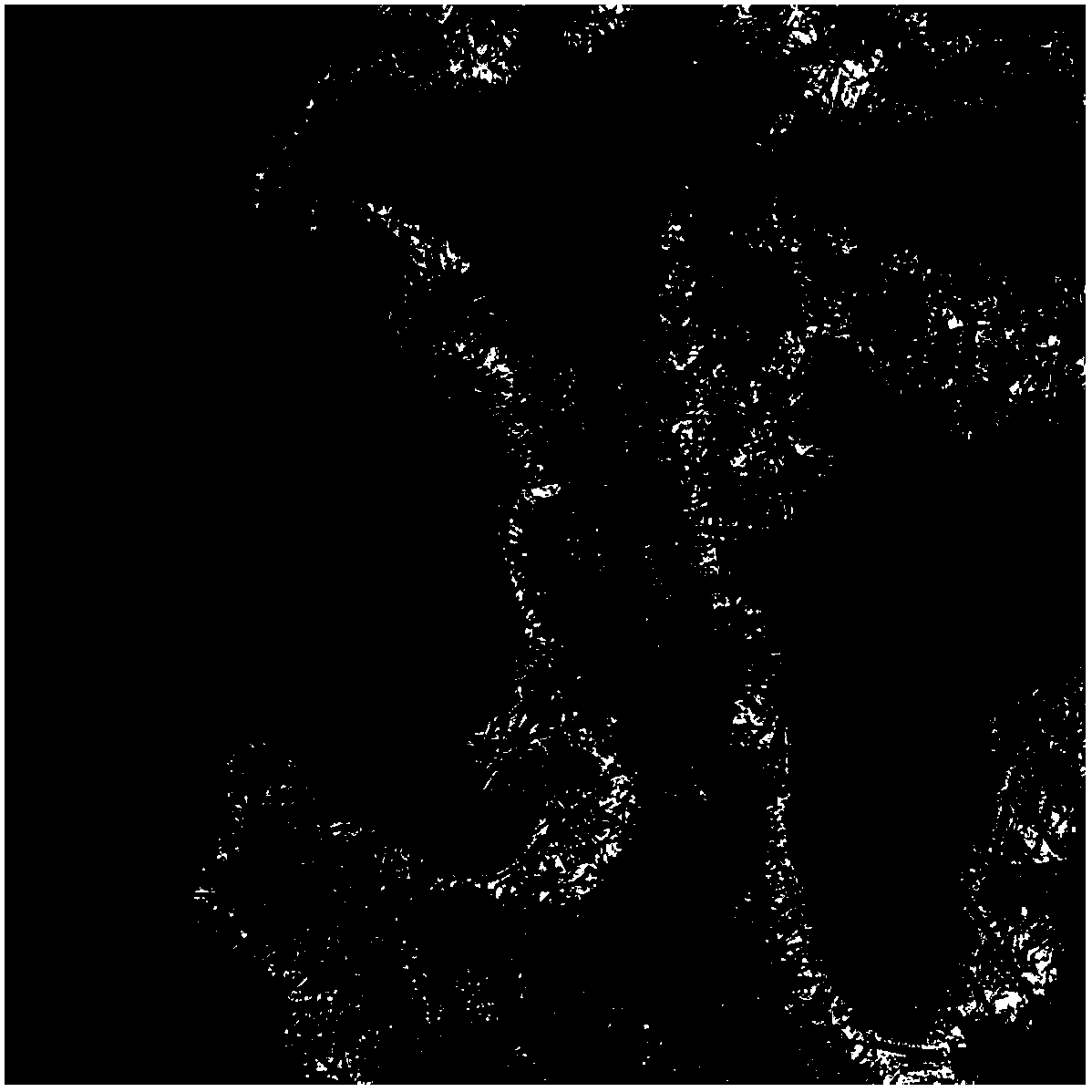

[0024] This embodiment is to the prepared MnO 2 / Carbon fiber tube composite electrode material for TEM characterization, such as image 3 Shown, MnO 2 It is a nanorod structure with a diameter of 6-10nm and a length of 50-150nm, which is densely attached to the surface of the carbon fiber tube. Compared with the sample obtained in Example 2, MnO 2 The content is further increased, and the growth is more intensive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com