A method for producing antimony white by removing arsenic from high antimony secondary soot

A technology of antimony white and arsenic removal, which is applied in the direction of improving process efficiency, etc., can solve the problems of low antimony direct recovery rate, declining benefit, low production efficiency of antimony white, etc., and achieve the effect of reducing production cost and widening resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

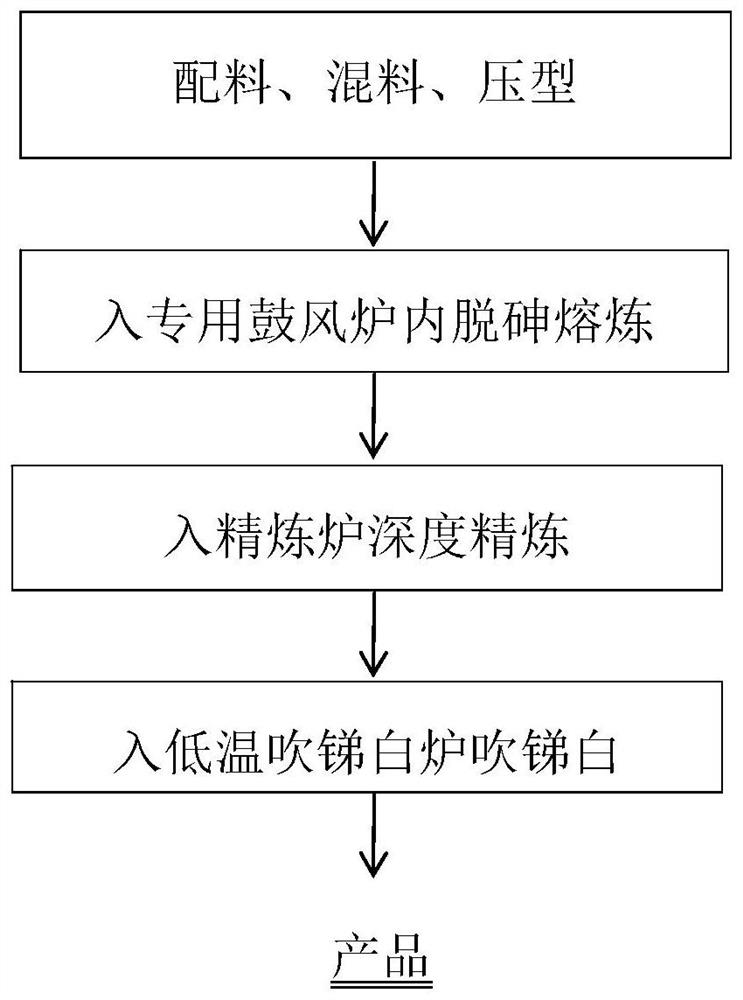

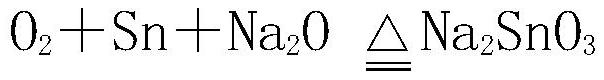

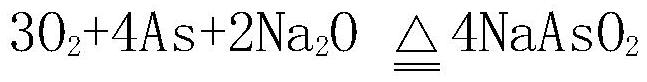

Method used

Image

Examples

Embodiment 1

[0024] Carry out trial production with a certain company in Leiyang by the method of the present invention, the specific circumstances are as follows: prepare the raw materials for production and see the following table for details:

[0025] Table 1 production raw material standby table

[0026]

[0027] Step 1, utilize the company's lead smelting system equipment to batch and press according to the method of the present invention. The specific ingredient ratio is: ①High antimony secondary smoke: ②Flux soda ash: ③Low temperature carbon reducing agent starch=79︰16︰5. According to this recipe, adjust the water to 12%, press it into a cylindrical material ball of φ120×H120, and air dry it for later use.

[0028] Step 2: Improve the blast furnace, the tuyere is set to 5 layers of tuyeres, the tuyere layer spacing is 0.6m, the bottom coke layer adopts a blast furnace system with 3.0m high coke columns, the hearth area is 0.78㎡, φ1.0m. Add the bottom focus fire, and control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com