Arsenic removal and desulfurization device and method for arsenic-containing and sulfur-containing metal ores

A technology of desulfurization device and sulfur metal, which is applied in the field of arsenic and desulfurization devices for arsenic-containing and sulfur-containing metal ores, and can solve problems such as difficulty, large investment, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

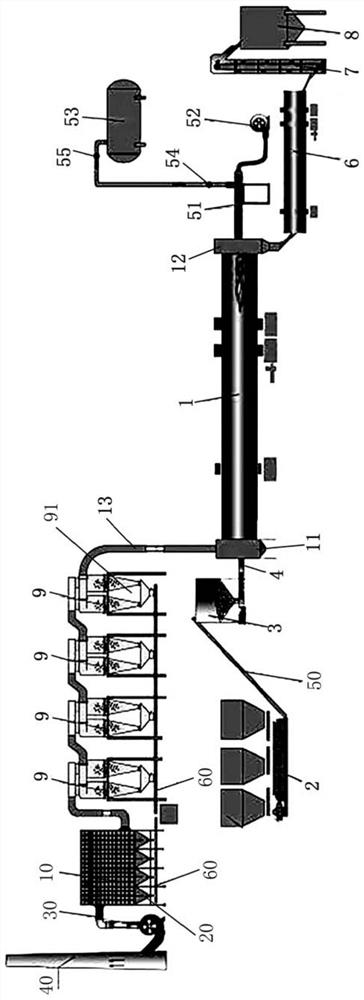

Image

Examples

Embodiment 1

[0066]This embodiment is mainly applied to copper-gold ore with high arsenic content, and it is required that the arsenic content and sulfur content in the clinker obtained should be low; the method is as follows:

[0067] After being ground into copper-gold ore powder, the copper-gold ore powder, coke and sodium phosphite are put into a twin-shaft mixer according to the weight ratio of 95%, 2%, and 3%, and stirred to form a mixed material;

[0068] Then it is sent to the first silo through the belt conveyor, and then the mixed material is sent to the rotary kiln through the first conveying device, and is dried under 28 standard atmospheric pressure, and the burner is used to cooperate with the gas source and the fan. Combustion is generated for heating, the drying temperature is 250 degrees, and the drying time is 2 hours, and the crystal water in the copper-gold ore powder is removed;

[0069] After drying, pre-reduction treatment is carried out, and the burner continues to ...

Embodiment 2

[0074] This embodiment is mainly used in the clinker that requires low arsenic content but high sulfur content. This is because the high sulfur content of copper concentrate helps the fluidity of the furnace. For this special Requirements, adjust the method as follows:

[0075] After the copper-gold ore containing arsenic and sulfur is ground into copper-gold ore powder, the copper-gold ore powder, coke and sodium phosphite are put into a twin-shaft mixer according to the weight ratio of 95%, 2% and 3% to form a uniform mixture. material;

[0076] Then it is sent to the first silo through the belt conveyor, and then the mixed material is sent to the rotary kiln through the first conveying device, and is dried under 28 standard atmospheric pressure, and the burner is used to cooperate with the gas source and the fan. Combustion is generated for heating, the drying temperature is 250 degrees, and the drying time is 1 hour to remove the crystal water in the copper-gold ore powde...

Embodiment 3

[0125] After the copper-gold ore containing arsenic and sulfur is ground into copper-gold ore powder, the copper-gold ore powder, coke and sodium phosphite are put into a twin-shaft mixer according to the weight ratio of 95%, 2% and 3% to form a uniform mixture. material;

[0126] Then it is sent to the first silo through the belt conveyor, and then the mixed material is sent to the rotary kiln through the first conveying device, and is dried under 30 standard atmospheric pressure, and the burner is used to cooperate with the gas source and the fan. Combustion is generated for heating, the drying temperature is 250 degrees, and the drying time is 1.5 hours to remove the crystal water in the copper-gold ore powder;

[0127] After drying, pre-reduction treatment is carried out, and the burner continues to heat to form a multi-stage temperature zone in the rotary kiln. When the temperature reaches 500 degrees, the pre-reduction treatment starts, and the time is 1.5 hours;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com