A latent heat recovery water heater

A water heater and latent heat technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of no latent heat recovery, environmental pollution, inconvenient disassembly and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

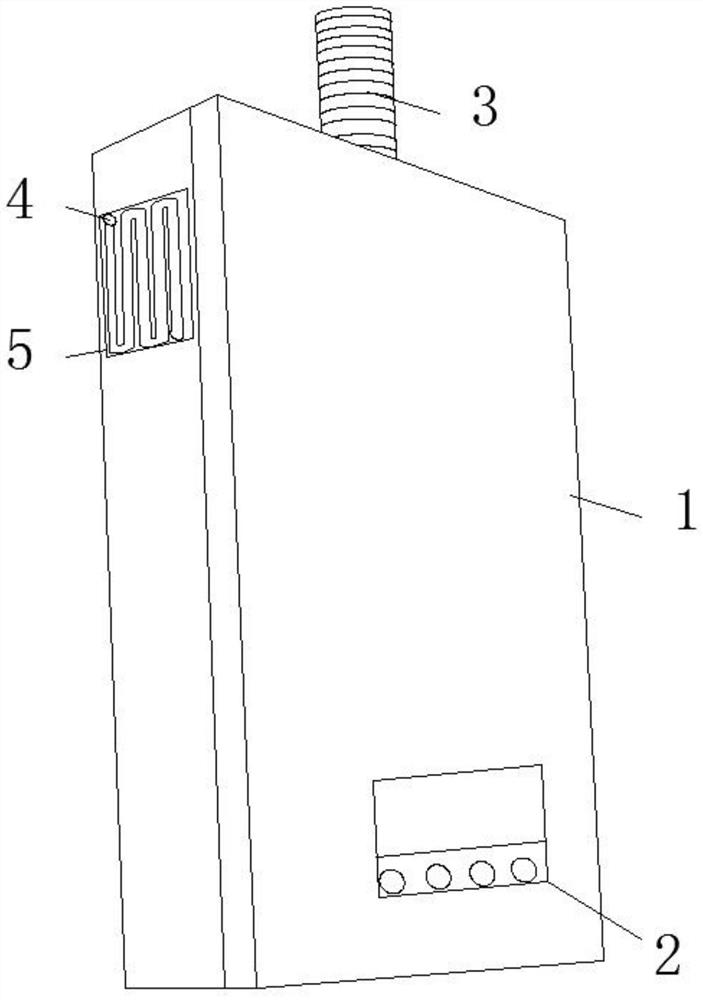

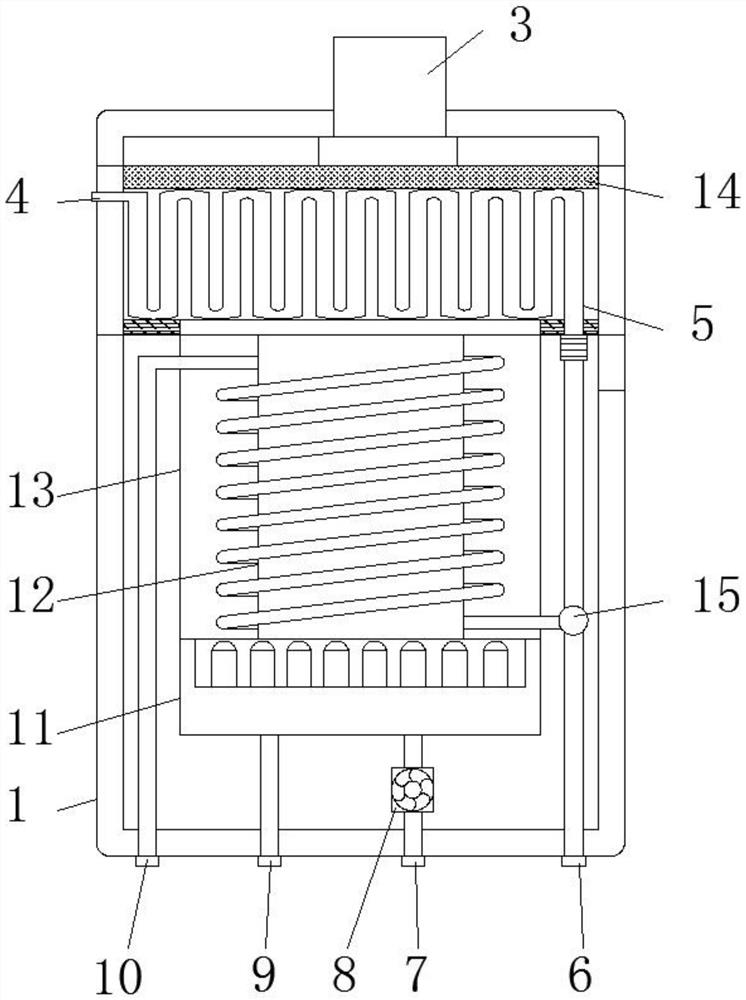

[0021] see Figure 1-2 , this embodiment provides a latent heat recovery type water heater, including a water heater shell 1, a microcomputer main controller 2 is embedded in one side of the water heater shell 1, a smoke exhaust pipe 3 is installed on the top of the water heater shell 1, and the water heater shell A second heat exchanger 5 is embedded on the side of the body 1 close to the exhaust pipe 3, a second heat exchanger water outlet 4 is arranged on one side of the second heat exchanger 5, and a second heat exchanger 5 is installed on the top of the second heat exchanger 5. The choke plate 14, the bottom of the smoke exhaust pipe 3 is provided with a filter inner core, the top of the choke plate 14 is provided with a return air cavity, the filter core is embedded in the return air cavity, and the bottom of the second heat exchanger 5 is provided with a combustion chamber. Chamber 13, the bottom of the second heat exchanger 5 is equipped with a thermal insulation board...

Embodiment 2

[0024] see Figure 1-2 , on the basis of Embodiment 1, a further improvement has been made: the interior of the burner 11 is provided with a plurality of flame nozzles, which accelerates the combustion efficiency and improves the instant hot water supply performance of the water heater, the water inlet 6, the air inlet 7, the gas One side of the inlet 9 and the hot water outlet 10 is provided with a mounting screw sleeve, threaded connection, stable connection, convenient installation, and the inside of the mounting screw sleeve is provided with a sealing gasket, which is sealed and protected, ensuring the stability of the material dredging process. Avoid leakage.

[0025]Wherein, the four corners of the water heater housing 1 are equipped with anti-collision foot pads, and the four corners are anti-collision protection. When the outer four corners are hit, the buffer performance can be improved to prevent the internal components from being damaged. The second heat exchanger 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com