MEMS capacitor film vacuum gauge

A thin film and vacuum technology, applied in vacuum gauges, measuring devices, instruments, etc., can solve the problems of long distance between the front-end measurement circuit and the vacuum gauge, limited vacuum measurement range, and not integrated together, so as to suppress the influence on the measurement , compact structure, and the effect of increasing the basic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

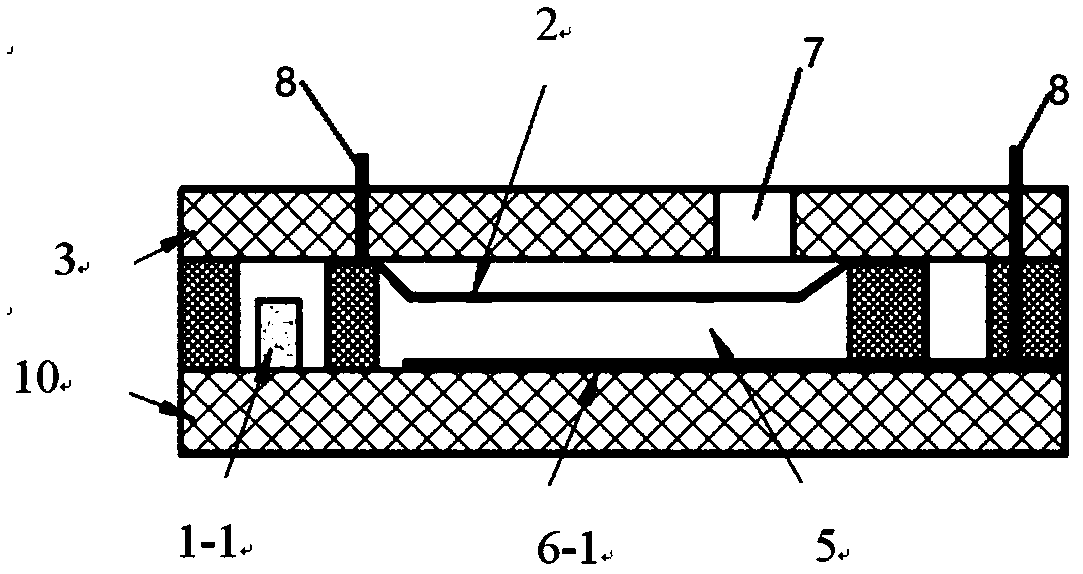

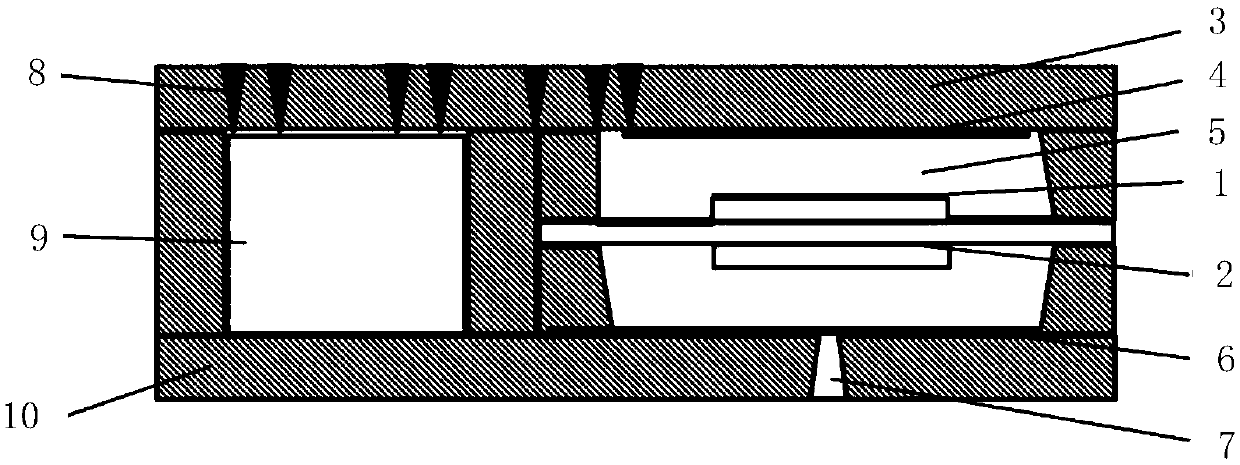

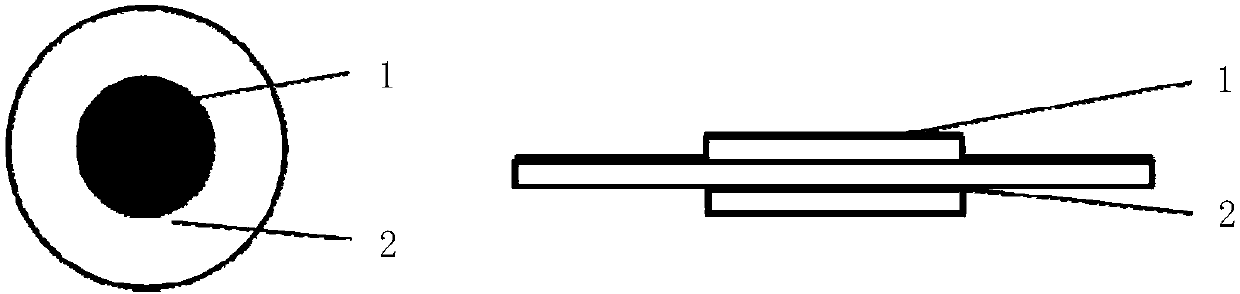

[0022] At present, the pressure-sensitive films of MEMS capacitive film vacuum gauges are mostly square or rectangular films, such as figure 1 As shown, the air inlet 7 is arranged on the upper substrate 3, the pressure-sensitive film 2 is located below the air inlet 7 as a moving electrode, and the metal electrode plated on the lower substrate 10 by coating technology is used as a fixed electrode 6-1. A vacuum chamber 5 is formed between the pressure-sensitive film 2 and the lower substrate 10 through silicon wafer bonding under high temperature conditions, and the getter 1-1 is concentrated on one side of the vacuum chamber to maintain the vacuum degree of the vacuum chamber 5 . The distance between the front-end measurement circuit and the vacuum gauge is relatively long, and they are not integrated together. The vacuum gauge with this struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com