Lattice structure with high energy dissipation capacity based on laser additive manufacturing

A lattice structure and laser additive technology, which is applied in the direction of additive processing, special data processing applications, instruments, etc., can solve the problems of uneven material performance and difficult quality control, and achieve the effect of rapid and accurate preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

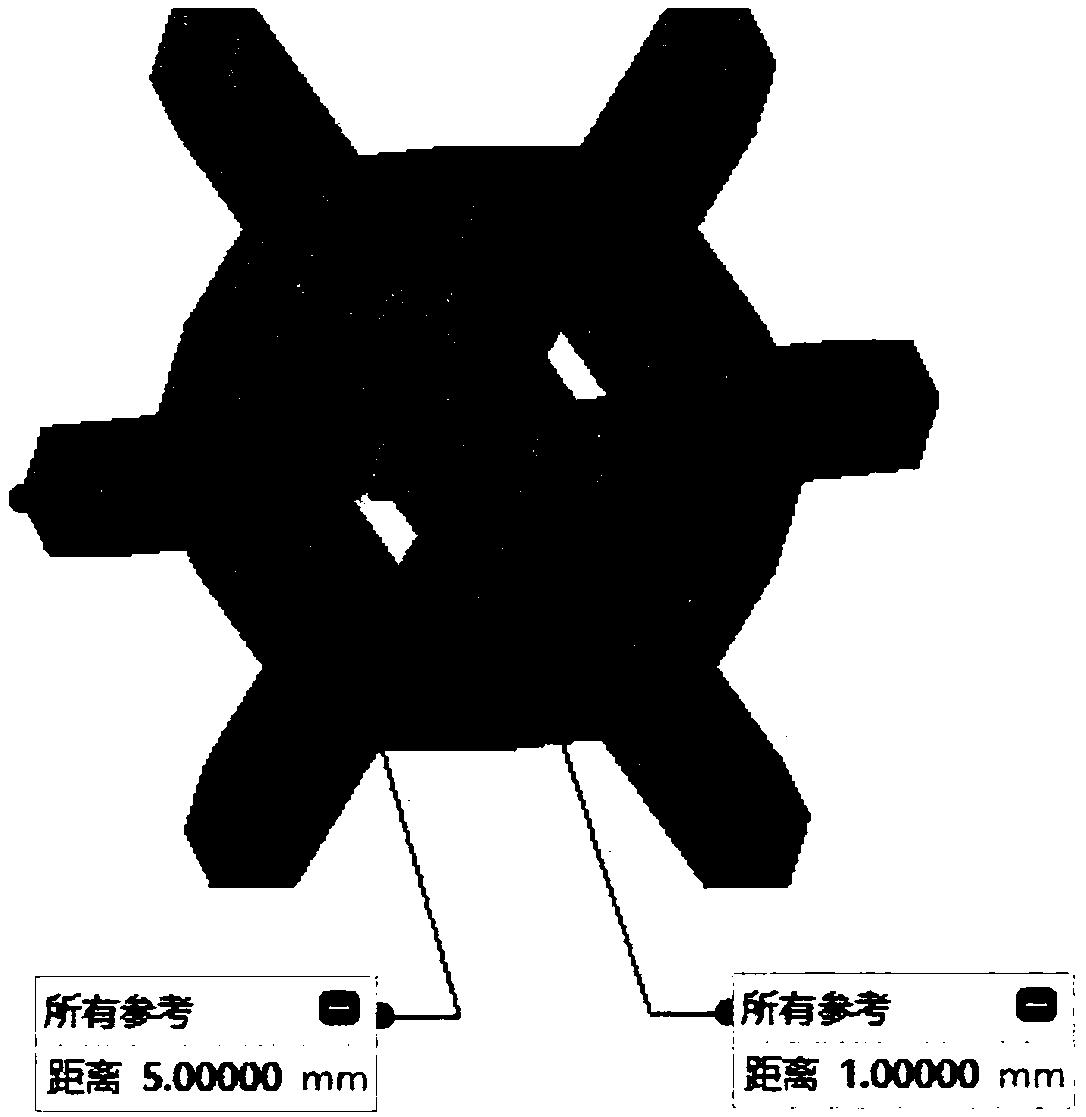

Embodiment 1

[0019] A lattice structure with high energy dissipation capability based on laser additive manufacturing. Determine the length of the lattice structure as 120mm, width 40mm, and height 10mm according to the needs, and then array multiple cell structures along three directions to obtain the required lattice structure.

[0020] The construction method of the cell structure is as follows:

[0021] Step 1. Given a virtual cube arbitrarily, the side length of the virtual cube is 5mm; the diameter is 1mm;

[0022] Step 2, construct 8 regular tetrahedrons; choose the vertex of a cube as a vertex of the regular tetrahedron; the center points of the three faces of the cube adjacent to the vertex are the other three vertices of the regular tetrahedron; repeat In this step, 8 regular tetrahedrons can be constructed;

[0023] Step 3: Connect the center of gravity of each regular tetrahedron to the vertices to obtain 4 cell rods; repeat this step to obtain 32 cell rods; then the cell str...

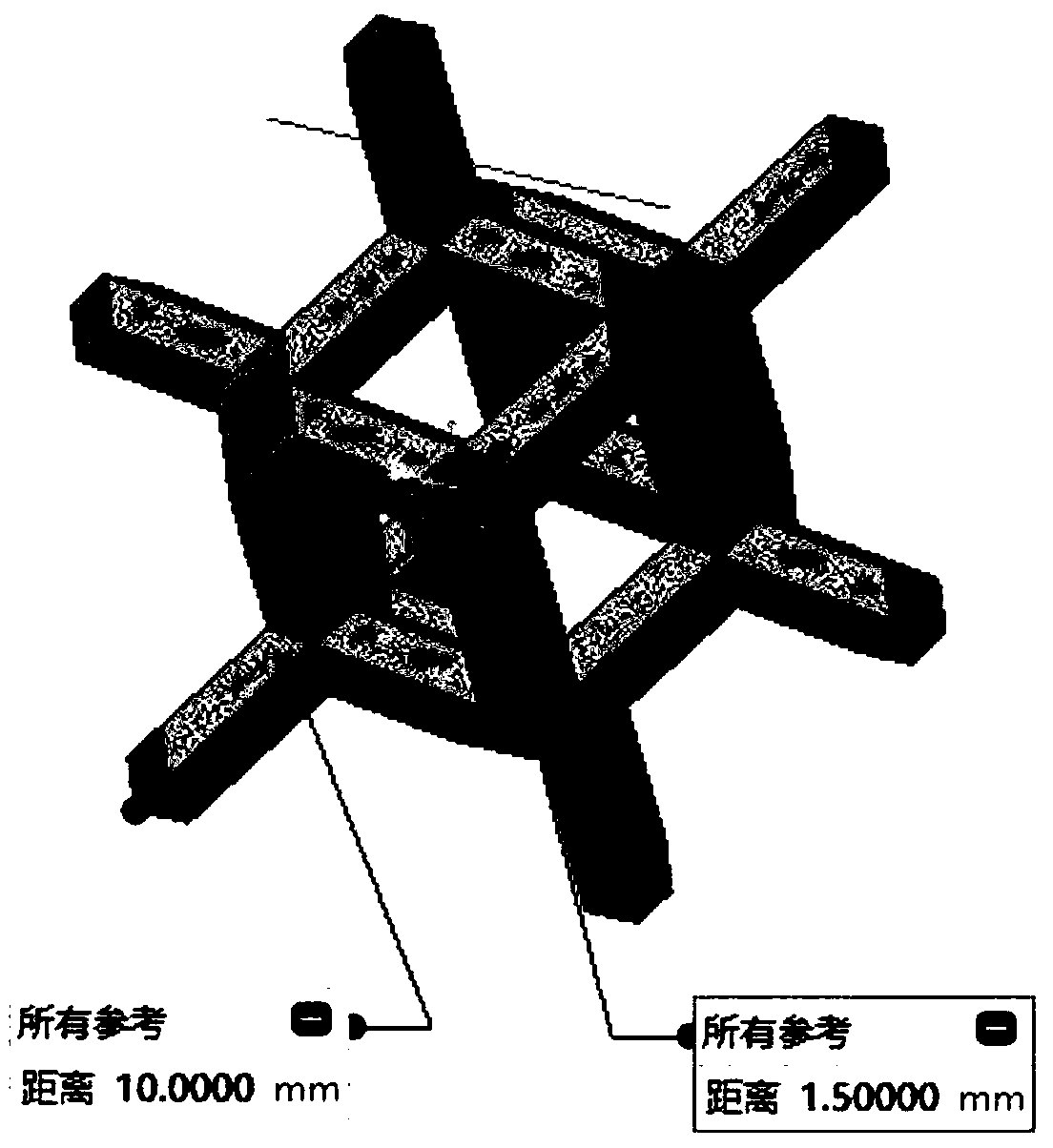

Embodiment 2

[0027] A lattice structure with high energy dissipation capability based on laser additive manufacturing. Determine the length of the lattice structure as 120mm, width 40mm, and height 10mm according to the needs, and then array multiple cell structures along three directions to obtain the required lattice structure.

[0028] The construction method of the cell structure is as follows:

[0029] Step 1. Given a virtual cube arbitrarily, the side length of the virtual cube is 10mm; the diameter is 1.5mm;

[0030] Step 2, construct 8 regular tetrahedrons; choose the vertex of a cube as a vertex of the regular tetrahedron; the center points of the three faces of the cube adjacent to the vertex are the other three vertices of the regular tetrahedron; repeat In this step, 8 regular tetrahedrons can be constructed;

[0031] Step 3: Connect the center of gravity of each regular tetrahedron to the vertices to obtain 4 cell rods; repeat this step to obtain 32 cell rods; then the cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com