Novel unidirectional three-phase three-level rectifier based on soft switching technology

A three-level rectification, soft-switching technology, applied in electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., to achieve the effects of harmonic suppression, cost reduction, and stable system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

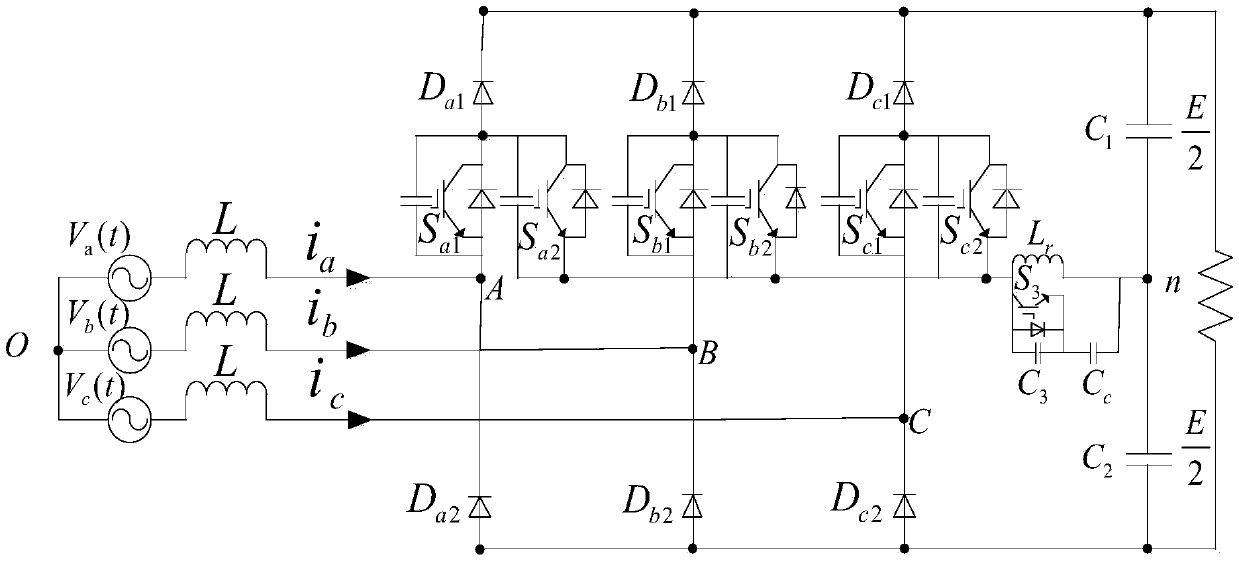

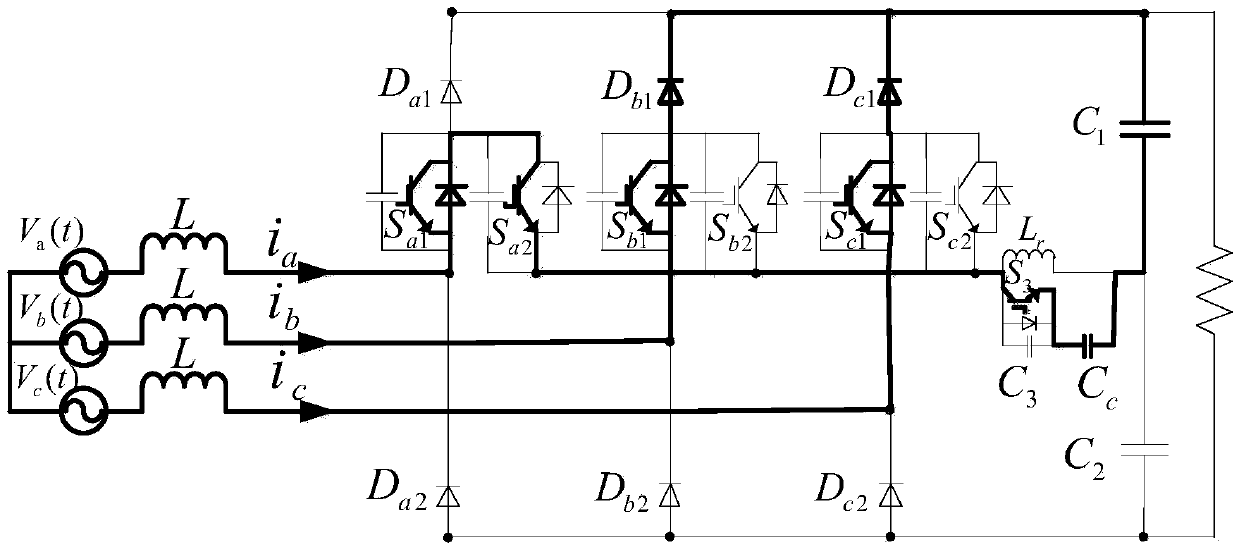

[0033] figure 1Shown is the main topology of a novel unidirectional three-phase three-level rectifier based on soft switching technology in the present invention, V a (t), V b (t), V c (t) are three-phase grid voltage respectively, i a i b i c is the grid-side input current, L is the grid-side filter inductance, the three-phase filter inductance L is equal in size, C 1 、C 2 is the upper and lower capacitors on the DC side, S a1 , S a2 , S b1 , S b2 , S c1 , S c2 For the six IGBT switch tubes that constitute the rectifier bridge, D a1 、D a2 、D b1 、D b2 、D c1 、D c2 6 fast recovery diodes that constitute the rectifier bridge.

[0034] The novel unidirectional three-phase three-level rectifier based on the soft switching technology of the present invention has three rectification states: state 1 is through the switch S X1 and diode D X1 The conduction is obtained; state 2 is when the switch S X1 and S X2 while on; state 3 is obtained by switch S X2 and diode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com