Material for high-efficient removal of non-methane total hydrocarbon from oil fume

A high-efficiency, methane technology, applied in gas treatment, membrane technology, other chemical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Multi-functional high specific surface honeycomb activated carbon with iodine value of 2600-2700 mg / g and specific surface area of 2800-3000 m 2 / g, ash <2 wt%;

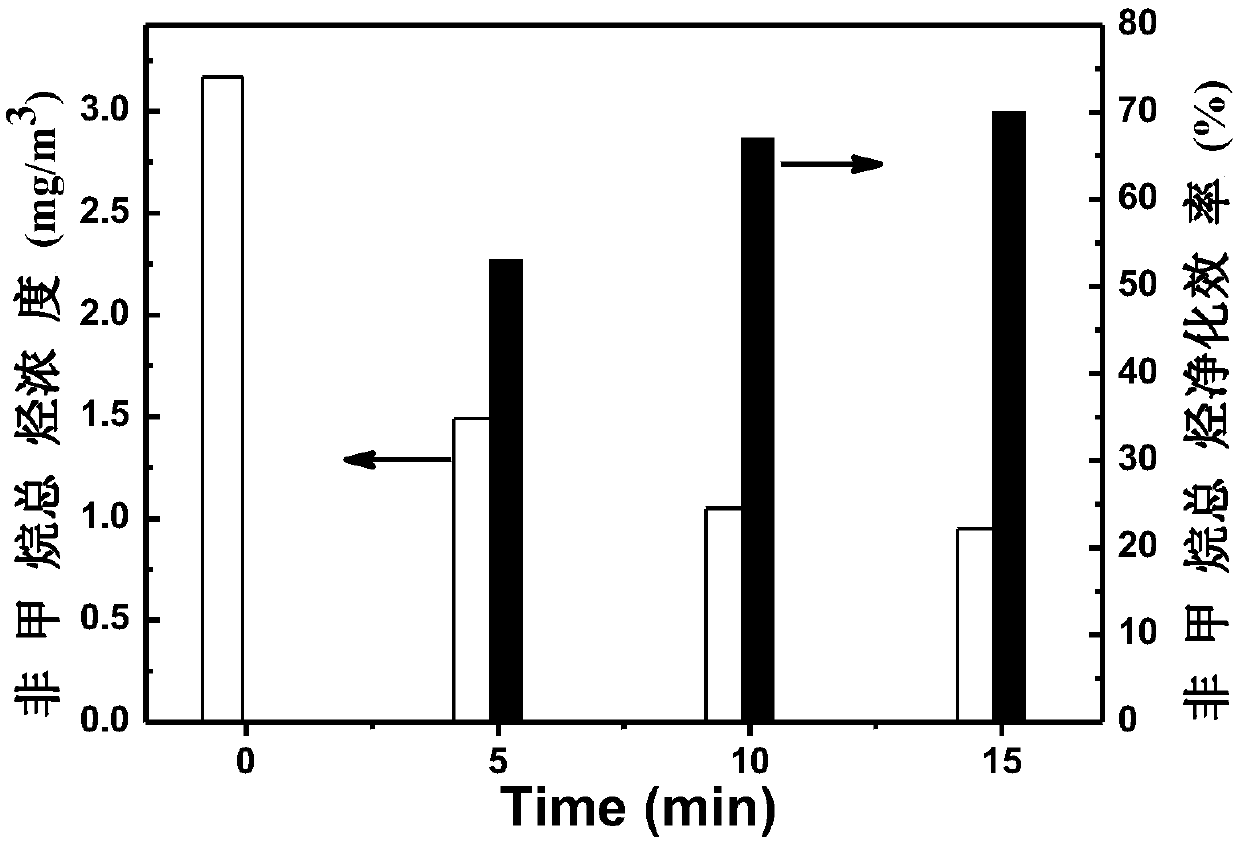

[0025] Prepare an aqueous solution with a concentration of sodium alginate of 14.3 mg / mL, a concentration of urea of 3.5 mg / mL, and a concentration of chitosan of 0.7 mg / mL, and soak the above-mentioned multifunctional high-specific surface honeycomb activated carbon in the solution for 5 minutes, and take out After that, it was dried naturally and dried in an oven at 80 °C for 6 h to obtain a high-performance MHCC honeycomb material. According to the data of the third-party testing agency, 900 g of the MHCC high-performance honeycomb material 3 / h air volume, within 15 minutes to 30 m 3 3.2 mg / m in the environment 3 The purification efficiency of non-methane total hydrocarbons reaches 70%.

Embodiment 2

[0027] Multifunctional high specific surface honeycomb activated carbon, iodine value 1900-2000 mg / g, specific surface area 2300-2500 m 2 / g, ash <2 wt%;

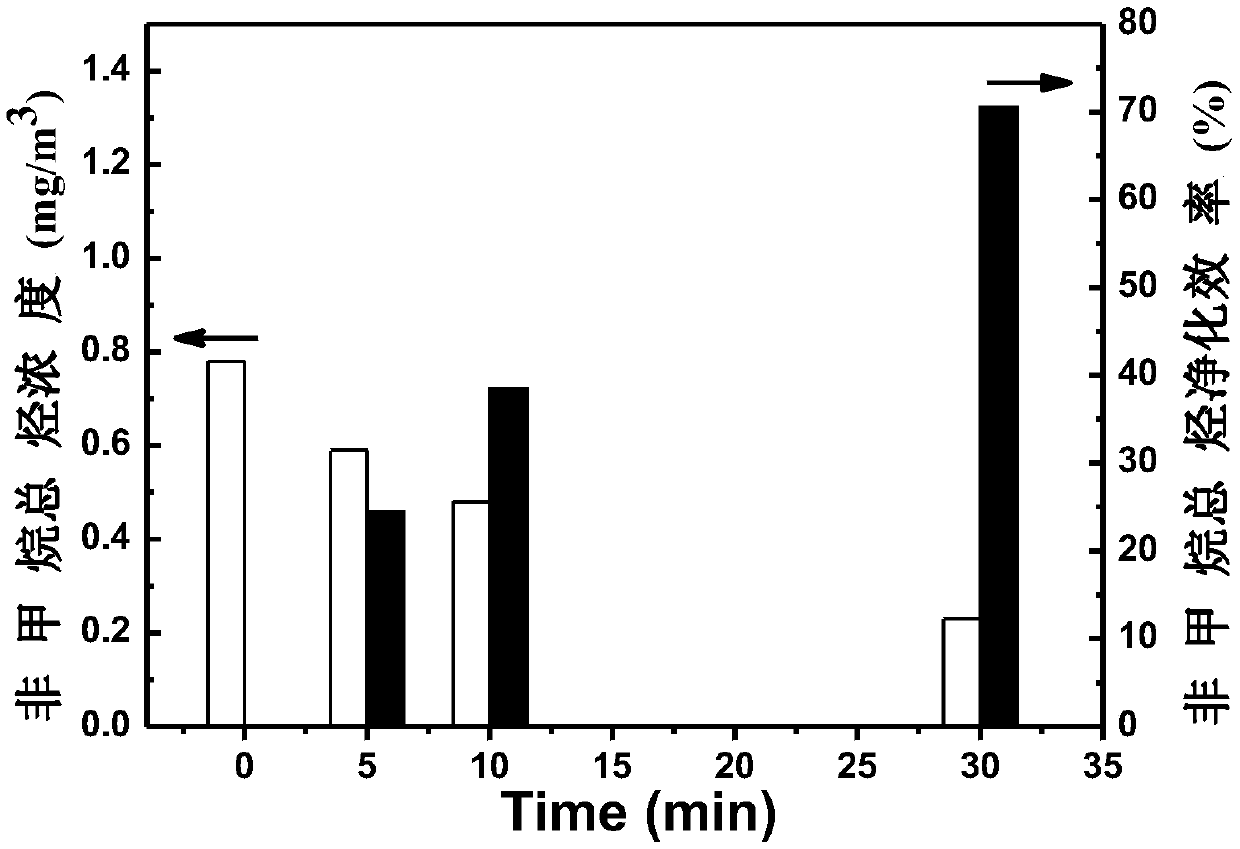

[0028] Prepare an aqueous solution with an oxalic acid concentration of 14.3 mg / mL, a nano-silver concentration of 0.35 mg / mL, and a hexadecyltrimethylammonium bromide concentration of 0.2 mg / mL, immerse the above carrier in the solution for 5 minutes, and take it out Naturally air-dried and dried in an oven at 80 °C for 6 h to obtain a high-performance MHCC honeycomb material. According to the data of the third-party testing agency, 900 g of the MHCC high-performance honeycomb material is 3 / h air volume, within 30 minutes to 30 m 3 0.76 mg / m in the environment 3 The purification efficiency of non-methane total hydrocarbons reaches 70%.

Embodiment 3

[0030] Multifunctional high specific surface honeycomb activated carbon, iodine value 1800-1900 mg / g, specific surface area 2000-2100 m 2 / g, ash <2 wt%;

[0031] Prepare an ethanol solution with a hexadecane bromide concentration of 7.15 mg / mL and a dodecyldimethylbenzyl ammonium bromide concentration of 0.9 mg / mL, soak the above carrier in the solution for 5 minutes, take it out and dry it naturally , and dried in an oven at 60 °C for 6 h to obtain a high-performance MHCC honeycomb material. According to the data of the third-party testing agency, 900 g of the MHCC high-performance honeycomb material 3 / h air volume, within 40 minutes to 30 m 3 1.5 mg / m in the environment 3 The purification efficiency of non-methane total hydrocarbons reaches 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com